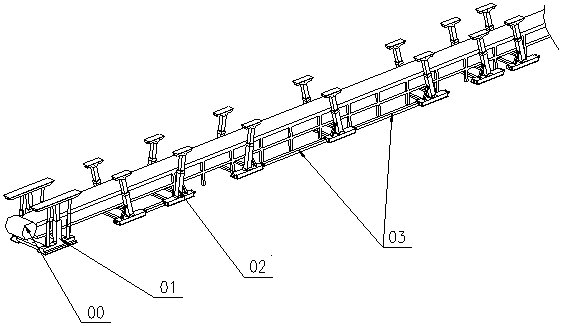

Crossheading belt conveyor foundation-free anchoring device

A belt conveyor and anchoring device technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of large engineering volume, no foundation anchoring device for down-trough belt conveyors, time-consuming and labor-intensive problems, and achieve reliable anchoring, convenient removal, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better illustrate the present invention, the implementation manners of the present invention are explained in detail below in conjunction with the accompanying drawings.

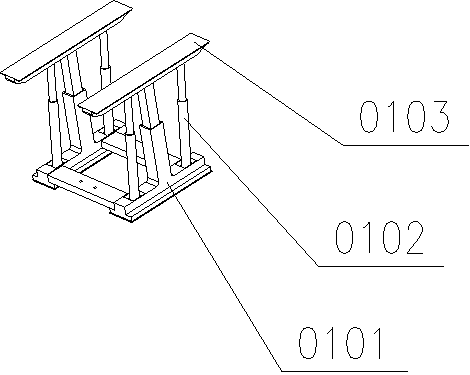

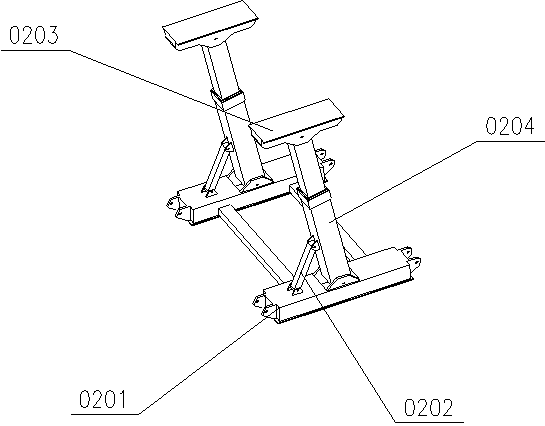

[0023] During installation, the special hydraulic support anchor unit is used to anchor the unloading frame of the head of the belt conveyor, and the column auxiliary rod anchor unit is used to anchor the belt conveyor driving part, tensioning part and take-up part; the special hydraulic support anchor unit and the column auxiliary The rod anchoring units are in the form of two rows, which are respectively arranged on the left and right sides of the belt conveyor, and are connected to the belt conveyor through connectors; the special hydraulic support and the column auxiliary rod anchoring unit are placed in the coal mine transportation trough, and the base is placed in the trough floor , supply fluid to the oil cylinder of the anchoring unit through the hydraulic pump station, the top beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com