Uncovered steel cable net tensioning operation platform used for constructing steel structures of high-altitude and medium-altitude buildings

A technology of operating platforms and steel cable nets, which is applied to building components, building structures, scaffolding supported by building structures, etc., can solve the problems of increased construction period, consumption, large material and labor costs, etc., to save construction period, simple process, The effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below according to the drawings and embodiments.

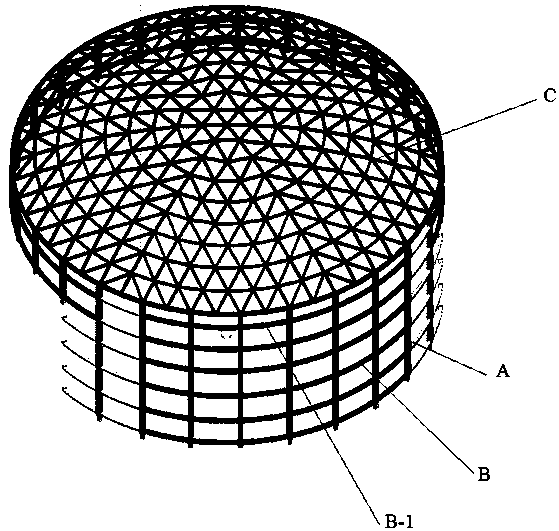

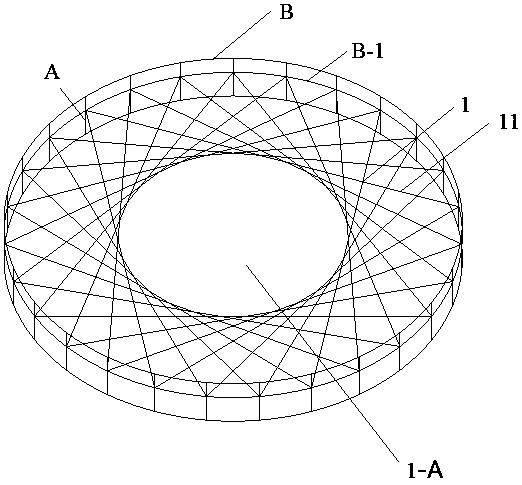

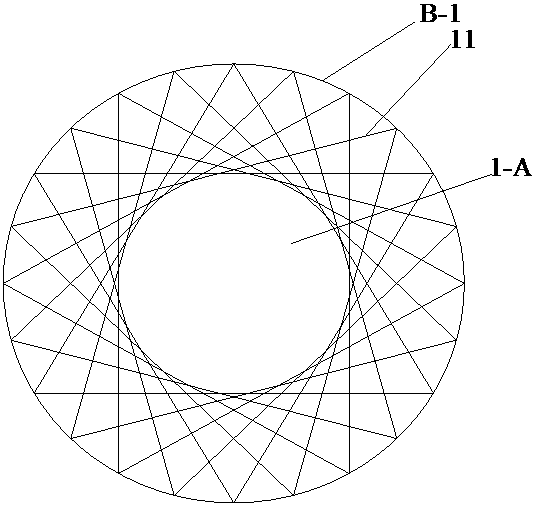

[0036] refer to Figure 1-Figure 8 , the present invention, a steel cable net 1 tensioning operation platform without a cover for construction of high and medium hollow building steel structures, is suitable for circular dome structure projects with a construction operation surface span of 18m to 40m and a construction load of no more than 3kN / m2 Project construction; at the same time, the main force steel cable 11 of the aerial operation platform needs to be fixed with the surrounding existing structures, and the bearing capacity of the existing structure should meet the bearing capacity requirements of the steel cable 11 platform. For this implementation case, the straw strips are set on the main body of the steel structure, the main body of the steel structure includes a plurality of steel columns A, a plurality of steel beams B, and an upper dome C, the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com