Equipment pipeline detection and control system based on LabVIEW

A pipeline detection and control system technology, applied in the pipeline system, mechanical equipment, electrical program control, etc., can solve the problems of lack of real-time alarm and automation, and achieve the effect of protecting the safety of the valve itself and enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

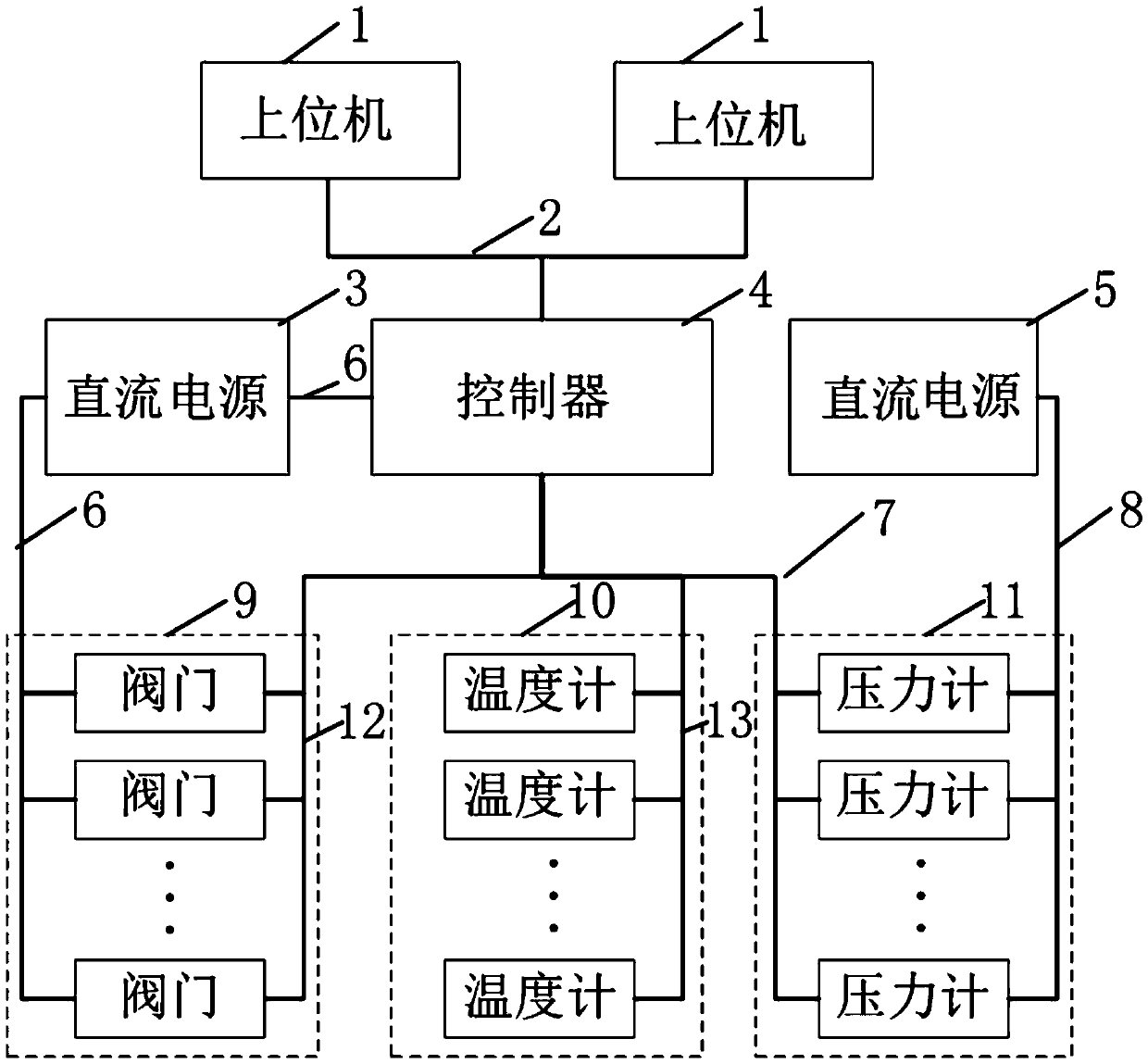

[0031] Such as figure 1 As shown, a LabVIEW-based equipment pipeline detection and control system includes at least one host computer 1, No. I DC power supply 3, controller 4, No. II DC power supply 5, valves 9, thermometers 10 and pressure gauges 11; Machine 1 is connected to controller 4, No. Ⅰ DC power supply 3 supplies power to controller 4 and valve 9, No. Ⅱ DC power supply 5 supplies power to pressure gauge 11; valve 9, thermometer 10 and pressure gauge 11 are respectively connected to controller 4 for electrical signals .

[0032] The upper computer 1 and the controller 4 are connected through an Ethernet cable 2, and the Ethernet cable 2 is a standard Ethernet twisted pair network cable.

[0033] The No. 1 DC power supply 3 provides DC 24V power supply for the controller 4 and the valve 9 through the power line 6, and the power line 6 is 2*1mm 2 cables.

[0034] The No. Ⅱ DC power supply 5 provides DC 24V power supply for the pressure gauge 11 through the shielded t...

Embodiment 2

[0046] Based on Embodiment 1, a method for equipment pipeline detection and control based on LabVIEW includes:

[0047] (I) data interaction between the controller 4 and the monitoring interface in the host computer 1;

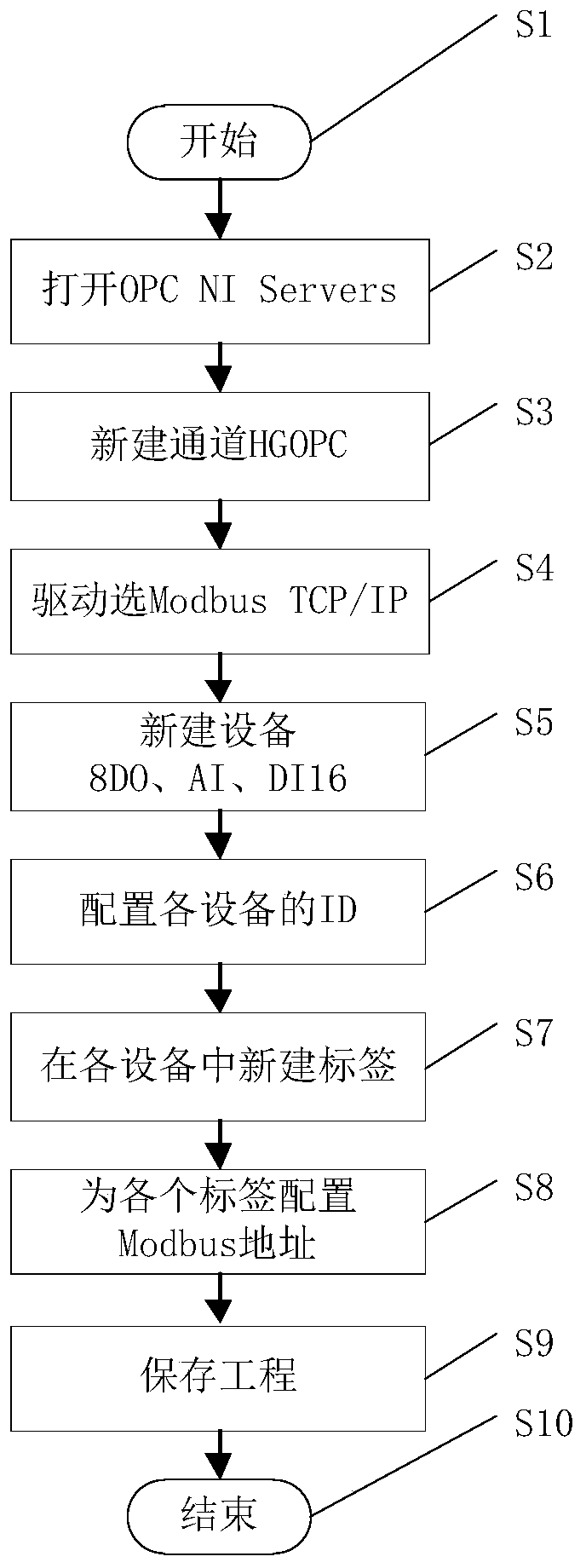

[0048] Such as figure 2 As shown, the real-time communication between the controller 4 and the upper computer 1 is realized through NI OPC Servers.

[0049] The data interaction between the controller 4 and the monitoring interface in the host computer 1 includes the following steps:

[0050] S1: start

[0051] S2: Open OPC NI Servers in NI of the start menu;

[0052] S3: Right-click the blank space, and name the new channel "HGOPC";

[0053] S4: Select Modbus TCP / IP Ethernet in the driver drop-down menu, keep clicking Next, and finally click "Finish";

[0054] S5: Create 3 new devices in the newly created channel "HGOPC" and name them "8DO", "AI" and "DI16" respectively;

[0055] S6: Configure the IDs of the newly created 3 devices;

[0056] S7: Creat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com