Orbital Automatic Phased Array Ultrasonic Scanner

A phased array and ultrasonic technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. Meet production needs and other issues to ensure stability and applicability, enhance flexibility, and reduce labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

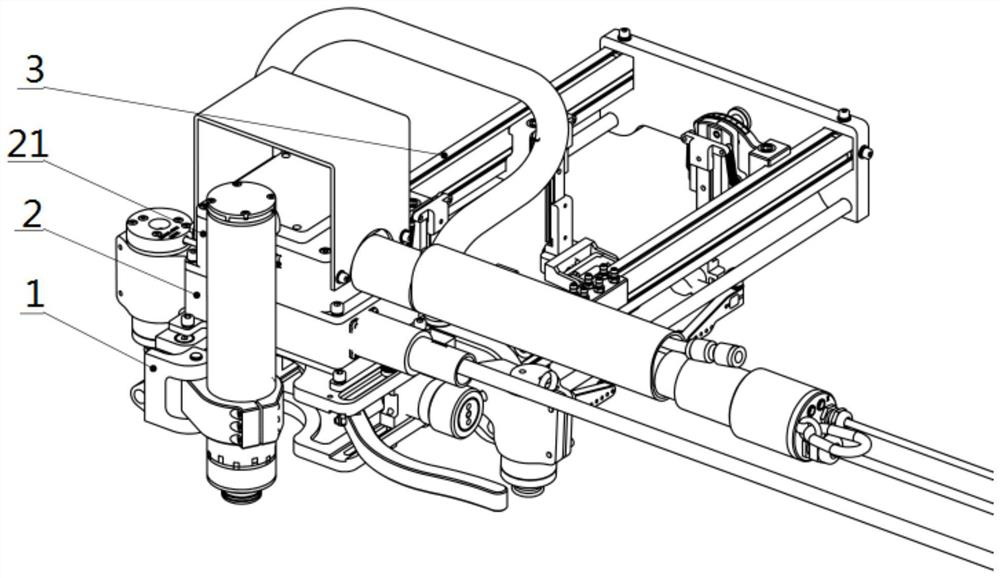

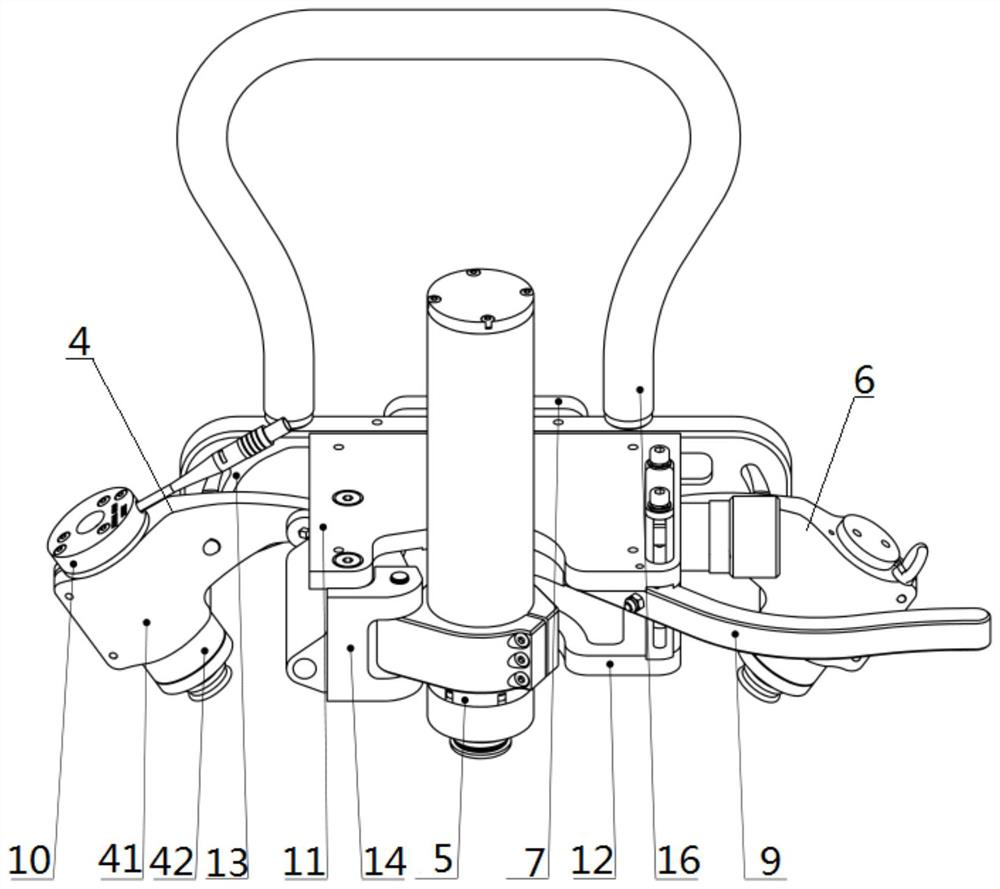

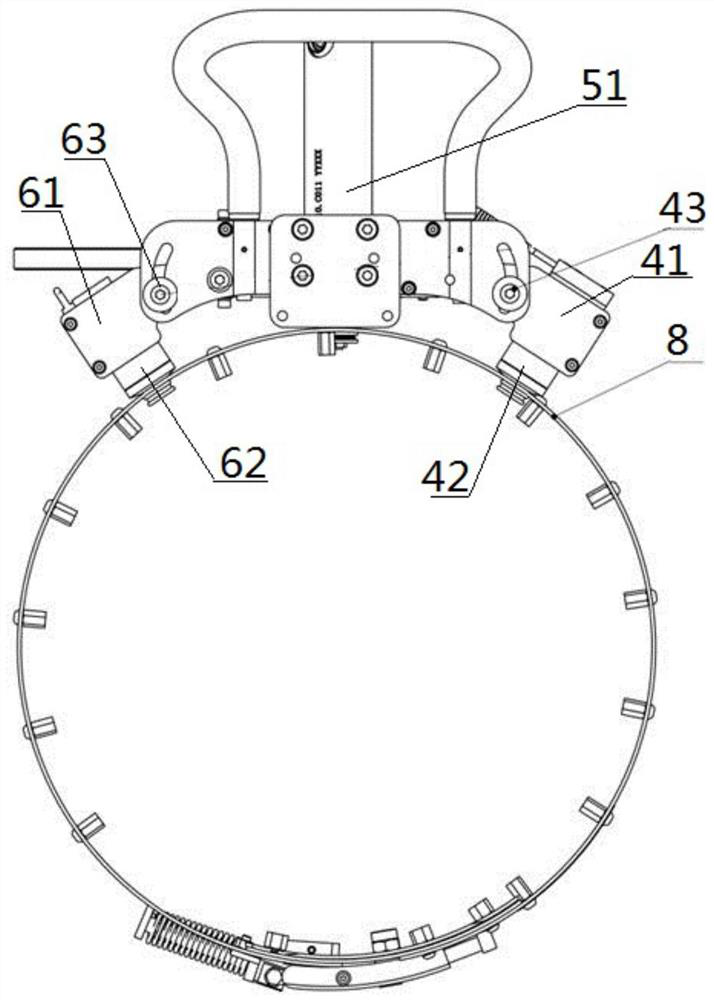

[0022] like Figure 1 to Figure 5 As shown, an orbital automatic phased array ultrasonic scanner includes: a main frame 1, a control box 2 and a probe frame 3, and four sides of the main frame 1 are sequentially provided with a first idler assembly 4, a drive assembly 5. The second idler assembly 6 and the connecting plate 7, the first idler assembly 4 and the second idler assembly 6 are adjustable and connected relative to the main frame 1 and are snapped on the same side of the track 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com