Solid electrolyte sheet and preparation method of sulfide solid electrolyte sheet

A technology of solid electrolyte and sulfide, which is applied in the direction of solid electrolyte fuel cells, solid electrolytes, non-aqueous electrolytes, etc., can solve the problem that solid electrolyte sheets are easily broken, achieve uniformity of sulfide solid electrolyte sheets, reduce thickness, and improve preparation success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a sulfide solid electrolyte sheet, comprising the following steps:

[0029] Step 1, the Li 2 S and P 2 S 5 The raw materials are mixed according to the set molar ratio, and ball milled to obtain the mixed powder; Li 2 S and P 2 S 5 The molar ratio of Li 2 S:P 2 S 5 =2.0~4.0; adopt ball mill to carry out ball milling, the rotating speed of ball milling is 370-510rpm, the time of ball milling is 30-40h;

[0030] Step 2, the mixed powder obtained in step 1 is crushed under a protective atmosphere and then sealed in a vacuum environment, and then heat-treated to obtain an electrolyte powder; the mixed powder is sealed in a vacuum quartz glass tube, and the vacuum degree of the vacuum quartz glass tube is lower than 0.1MPa; heat treatment temperature is 240-260℃, heat treatment time is 2-4h;

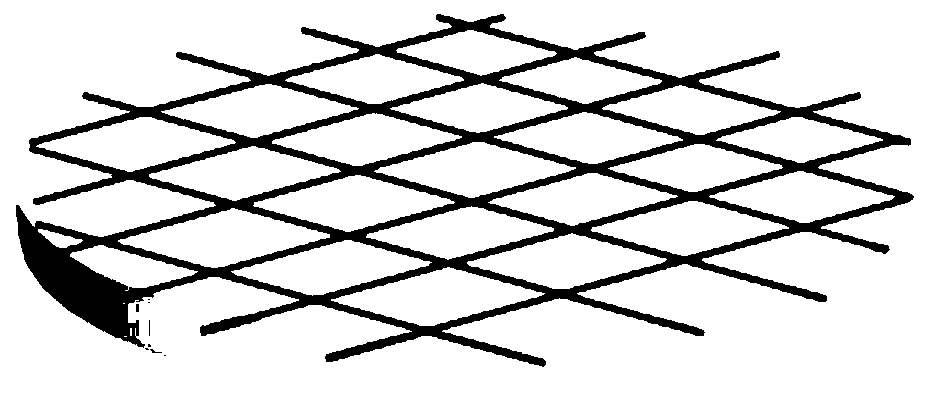

[0031] Step 3, take the polymer fiber skeleton and place it in a tableting mold, take out the electrolyte powder obtained in step 2 under a protective a...

Embodiment 1

[0034] Will Li 2 S and P 2 S 5 As the initial raw material, weigh Li 2 S mass 0.9827g, P 2 S 5 Mass 2.0173g, then Li 2 S and P 2 S 5 Place it in a 50mL zirconia ball mill jar (contains 10 ZrO particles with a diameter of 10mm) 2 Ball milling beads), and placed in the high-energy ball mill of the ball mill, the ball milling time is 40h, the ball milling speed is 370rpm, and the ball milling temperature is normal temperature; 2 2 (07 P 3 S 11 Sulfide solid electrolyte. After heat treatment and cooling, take out the powder in the glove box, and use a 450-mesh sieve to screen out the powder that meets the particle size.

[0035] The polymer fiber skeleton is cut and cut, and then placed in a tableting mold, the fired powder is evenly spread on the polymer fiber skeleton, and then directly compressed into a tablet under a tablet machine at a pressure of 400 MPa to obtain a polymer Li supported by the fibrous skeleton 7 P 3 S 11 Sulfide solid-state electrolyte sheet, ...

Embodiment 2

[0039] Will Li 2 S and P 2 S 5 As the initial raw material, weigh Li 2 S mass 1.1554g, P 2 S 5 Mass 1.8445g, then Li 2 S and P 2 S 5 Place it in a 50mL zirconia ball mill jar (contains 10 ZrO particles with a diameter of 10mm) 2 ball milling beads), and placed in a ball mill for high-energy ball milling, the ball milling time was 30 h, the ball milling speed was 510 rpm, and the ball milling temperature was normal temperature. After ball milling, in an argon-filled glove box (O 2 2 O3 P.S. 4 Sulfide solid electrolyte. After heat treatment and cooling, take out the powder in the glove box, and use a 600-mesh sieve to screen out the powder that meets the particle size.

[0040] The polymer fiber backbone is trimmed and placed in a tablet mold. Spread the fired powder evenly on the polymer fiber skeleton. Then it was directly compressed into tablets under a tablet press at a pressure of 360 MPa to obtain Li 3 P.S. 4 A sulfide solid electrolyte sheet, which has exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap