Undaria pinnatifida stem and leaf separator

A technology for stem-leaf separation and wakame, applied in the fields of application, food processing, food science, etc., can solve the problems of skin hazards, low separation efficiency, high labor cost, etc., and achieve the effects of preventing injury, simple production process, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

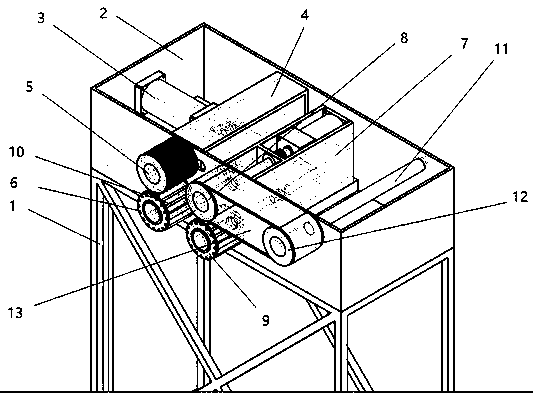

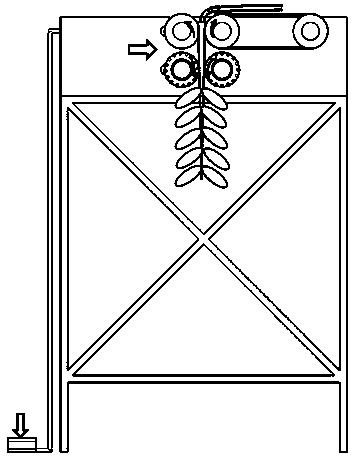

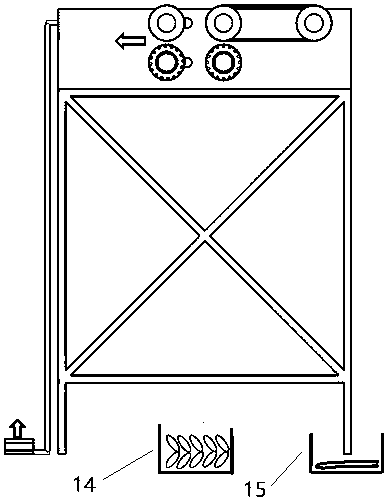

[0010] The specific embodiments of the present invention will be described below in conjunction with the drawings. Such as figure 1 , figure 2 , image 3 Shown: A wakame stem and leaf separator includes a frame 1 as a foundation, a shell 2 is supported on the top of the frame 1, and a traverse cylinder 3 is provided at one end of the shell 2; The working end of the traverse cylinder 3 is connected to the side wall of the traverse box 4, and the traverse box 4 is slidably connected in the housing 2, and the traverse box 4 can be in the length direction of the housing 2. The upper and lower reciprocating movement, the upper and lower traverse motors are arranged in the traverse box 4, the working end of the upper traverse motor is connected with the traverse stem drum 5, the work of the lower traverse motor The end is connected with the traverse blade roller 6, and the side wall of the housing 2 is also provided with long grooves matching the working shafts of the upper travers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com