Dental implant and method for its preparation

A dental implant and additive manufacturing technology, which is applied in the direction of prosthesis, additive manufacturing, pharmaceutical formulations, etc., can solve the problems of toxic elements, shedding, loosening of implants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Further, in the preparation method of the present embodiment, the specific steps of melting the titanium alloy powder using a laser selection method for melt the additive manufacturing process include:

[0037] S0, the titanium alloy rib is prepared by gas atomization method or an equal centrifugation method; wherein the gas atomization method comprises: pulling the smelting chamber to evacuate, titanium alloy rod before smelt Put the induction coil, melting power 100KW, after the rod is completely melted, passed into high purity argon, purity 4n, atomized pressure 3 to 7 MPa, collect powder; the like, the concentrate rotation, the method includes: indoor access is high purity Argon, purity 4n, pressure 0.04 MPa, rotational speed 26000 rpm, and collect powder.

[0038] S1, a three-dimensional model of the teeth implant, cutting the thickness of the slice to 10-30 μm, planning the scanning path, scanned by a nine-rich manifold, and the deflection angle is 36 ° -40 ° when sca...

Embodiment 1

[0043] A dental implant is made of titanium alloy powder, wherein the titanium alloy powder is composed of elements of the following mass fraction:

[0044] 16.5% TA, 4.5% Nb, 4.2% Zr, 0.0005% O, the rest is Ti.

[0045] In this embodiment, a method of preparing a tooth implant is specifically prepared by melting the titanium alloy powder, melting a reducing material manufacturing process, forming the dental implant;

[0046] Wherein, the titanium alloy powder is composed of an element such as a mass fraction:

[0047] 16.5% TA, 4.5% Nb, 4.2% Zr, 0.0005% O, the rest is Ti.

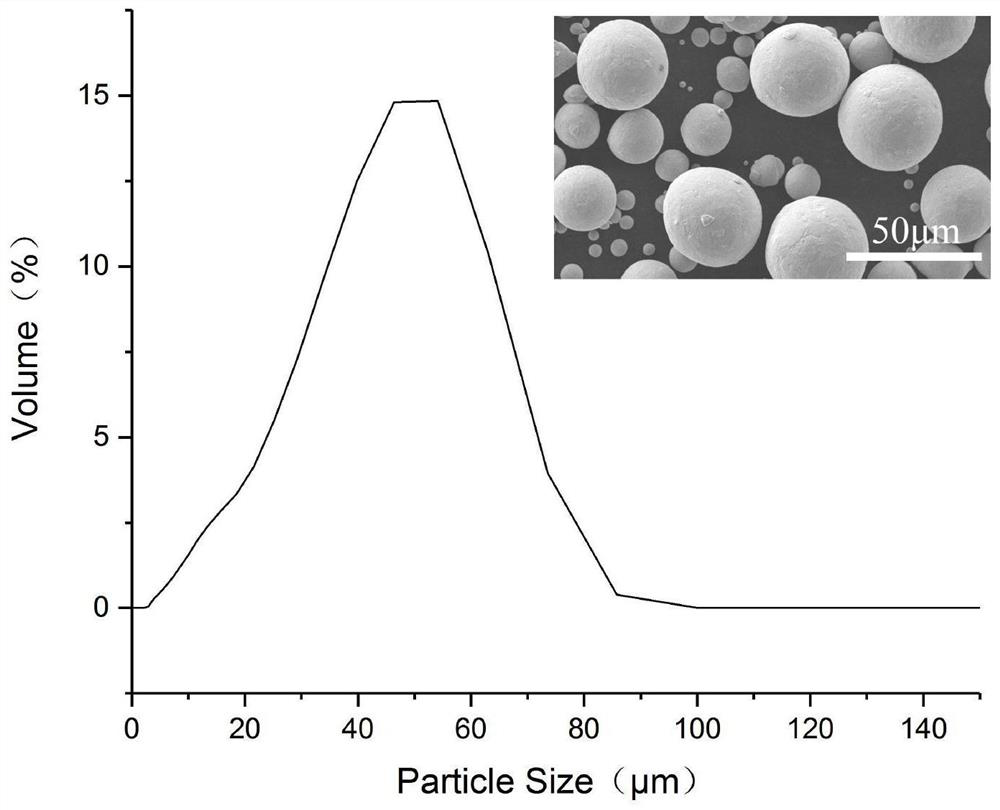

[0048] Further, in the preparation method of the present embodiment, the fluidity ≤ 25s / 50g of the titanium alloy powder is satisfied with the laser selection melting powder requirements; and / or, the titanium alloy powder has a particle size of 10-100 μm, further , D 10 Controlled 12μm, D 50 Controlled 40μm, D 90 Controlled at 64 μm.

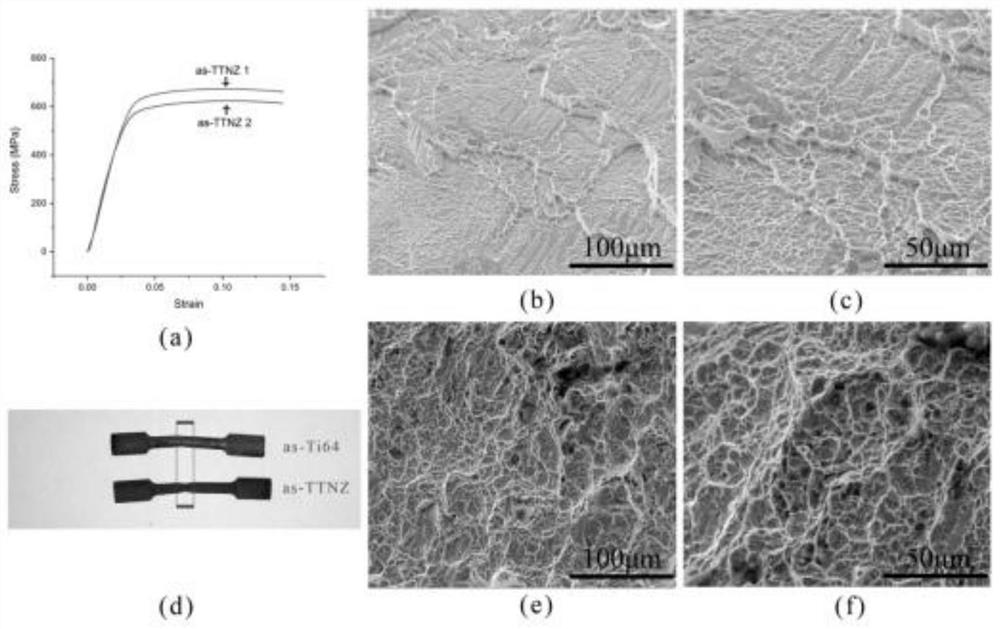

[0049] The titanium alloy powder in this example is combined figure 1 I...

Embodiment 2

[0063] A dental implant is made of titanium alloy powder, wherein the titanium alloy powder is composed of elements of the following mass fraction:

[0064] 15.5% TA, 3% Nb, 3% Zr, 0.0002% O, the rest is Ti.

[0065] In this embodiment, a method of preparing a tooth implant is specifically prepared by melting the titanium alloy powder, melting a reducing material manufacturing process, forming the dental implant;

[0066] Wherein, the titanium alloy powder is composed of an element such as a mass fraction:

[0067] 15.5% TA, 3% Nb, 3% Zr, 0.0002%, the rest is Ti.

[0068] Further, in the preparation method of the present embodiment, the fluidity ≤ 25s / 50g of the titanium alloy powder is satisfied with the laser selection melting powder requirements; and / or, the titanium alloy powder has a particle size of 10-100 μm, further , D 10 Control at 15μm, D 50 Controlled 43μm, D 90 Controlled at 67 μm.

[0069] Further, the step of preparing the titanium alloy powder to melt the addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap