Atomizing nozzle for lift pipe of catalytic cracking device

A catalytic cracking device and atomizing nozzle technology, which is applied in catalytic cracking, cracking, chemical instruments and methods, etc., can solve the problem that nozzles cannot produce fine droplet spray patterns, shutdown and replacement costs are unfavorable, nozzles are difficult to obtain performance, etc. problem, to achieve the effect of cutting oil and gas molecules, improving the atomization effect, and good pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

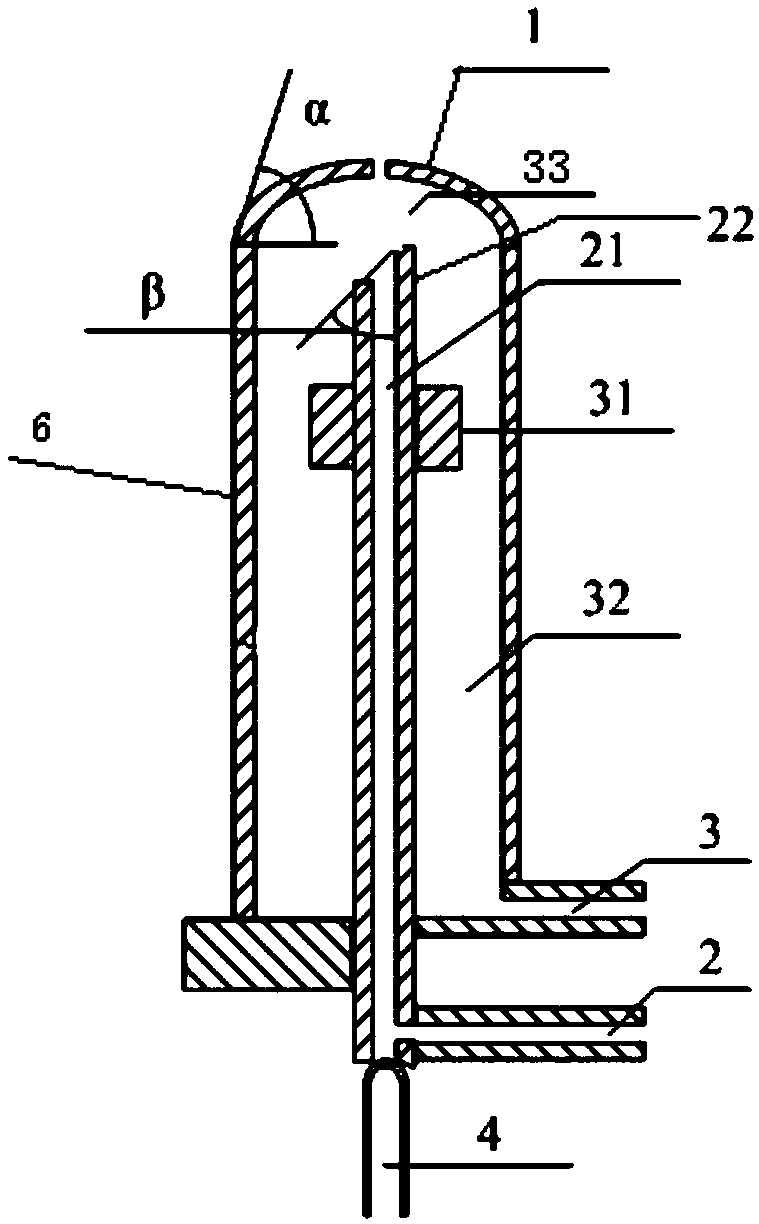

[0078] The atomizing nozzle for the riser of the catalytic cracking device adopted in this embodiment includes a nozzle main body, and the nozzle main body is a two-layer casing composed of an inner pipe 21 and an outer pipe 6, and the two ends of the two-layer casing are respectively It is an inlet port and an outlet port, the inlet port of the inner tube 21 is located outside the outer tube 6, and the outlet end of the inner tube 21 is located inside the outer tube 6;

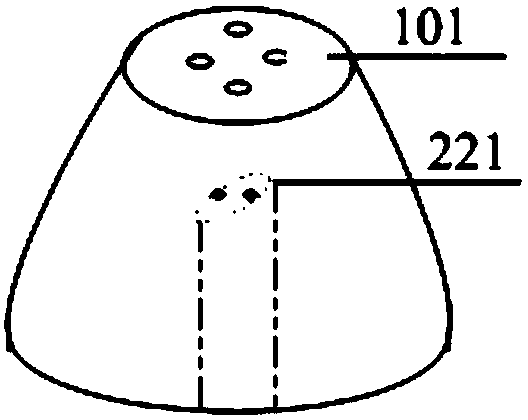

[0079]The outlet end of the outer tube 6 is provided with a second nozzle head 1, the second nozzle head 1 is a half-drum shape, the outlet end of the inner pipe 21 is provided with a first nozzle head 22, and the inlet end of the first nozzle head 22 is connected to the inner The outlet end of the pipe 21 is connected, the outlet end of the first nozzle head 22 is close to the outlet end of the second nozzle head 1, and the distance between the outlet end of the first nozzle head 22 and the outlet end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com