Preparation method of oil-conducting material

A slurry and graphene technology, applied in textiles and papermaking, tobacco, fiber chemical characteristics, etc., can solve the problems of low thermal conductivity, oil conductivity and oil storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0060] One embodiment, the preparation method of the oil-conducting material of powdery pure graphene, comprises the steps:

[0061] S1, forming, crushing the graphene to form a powder structure.

[0062] One embodiment, the preparation method of the oil-conducting material of powdery pure graphene, comprises the steps:

[0063] S1, forming, crushing the graphene to form a powder structure;

[0064] S2, annealing the shaped graphene oxide to form graphene.

[0065] One embodiment, the preparation method of the oil-conducting material of powdery pure graphene, comprises the steps:

[0066] S0, annealing unshaped graphene oxide to form graphene;

[0067] S1, forming, crushing the graphene to form a powder structure.

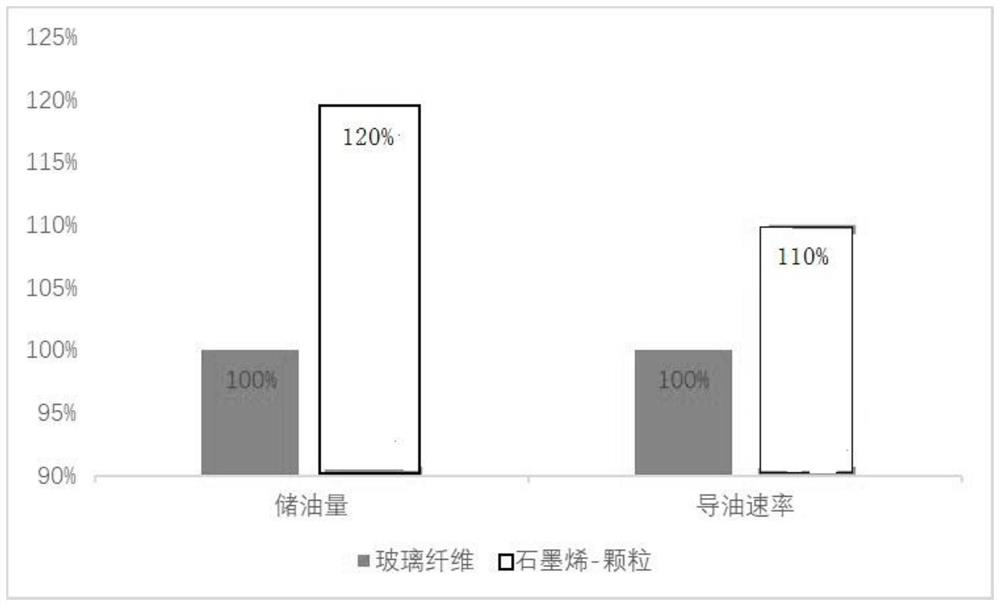

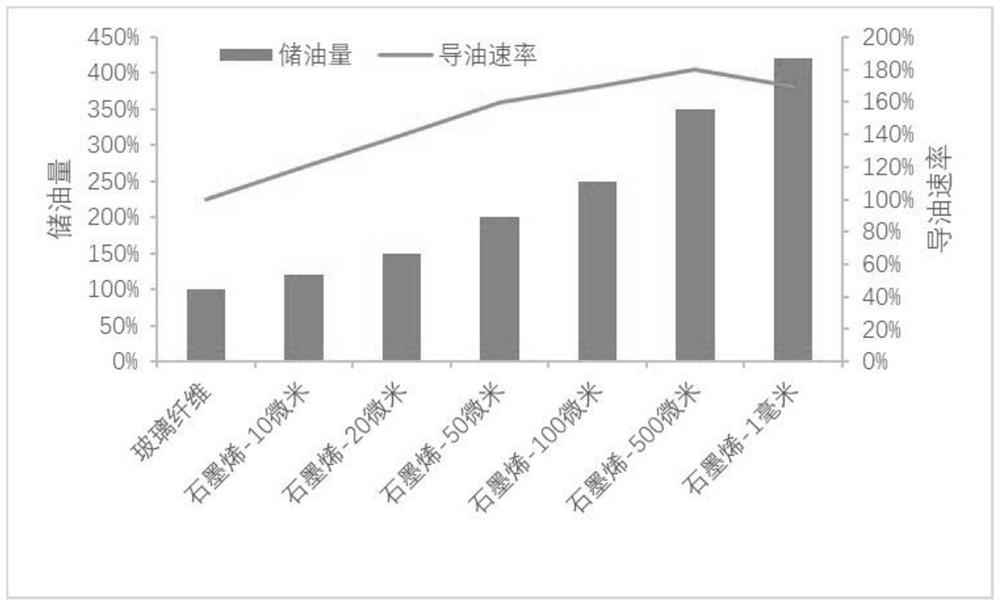

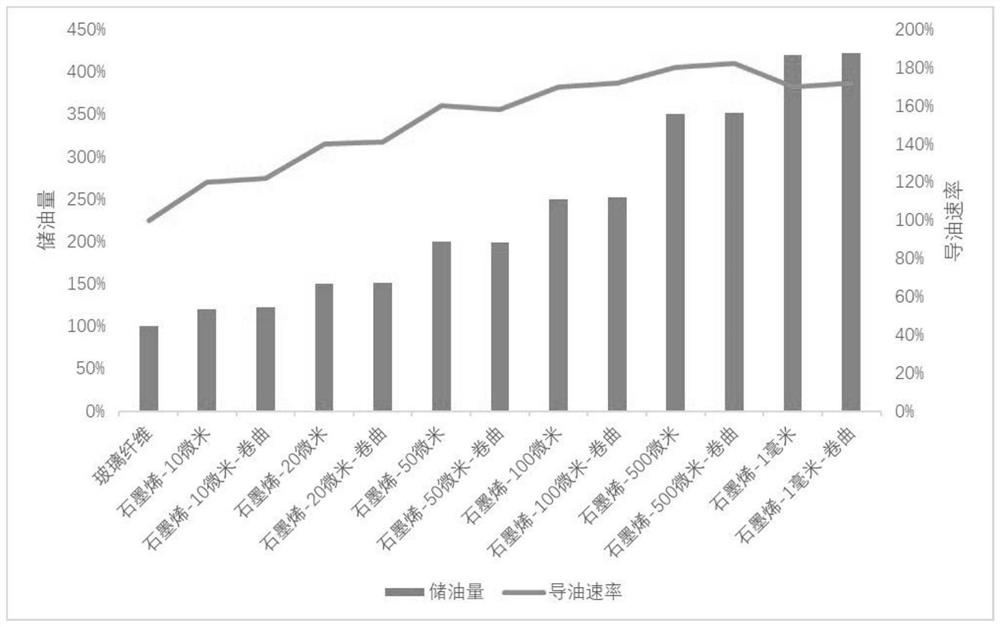

[0068] from figure 1 It can be seen that the oil storage capacity and oil conduction rate of graphene particles are higher than those of glass fibers.

[0069] A kind of embodiment, the preparation method of powdery pure graphene and band porous structure and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com