Vibration screening machine

A technology of vibrating screening machine and driving machine, which is applied in the fields of filtering, solid separation, dust removal, etc. It can solve the problems of working environment pollution, grain heat, mildew, deterioration, and mixing, etc., and achieves compact machine structure, simple structure principle, and unique design ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

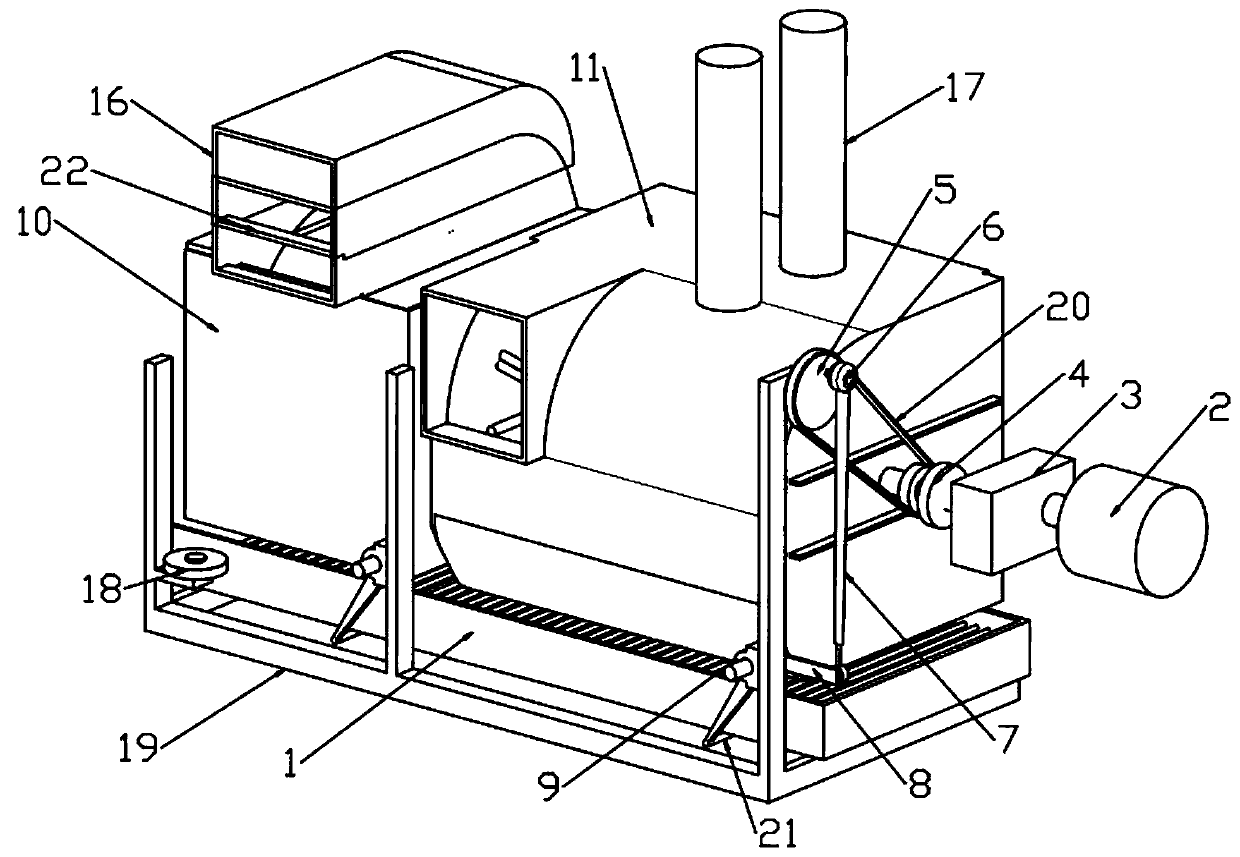

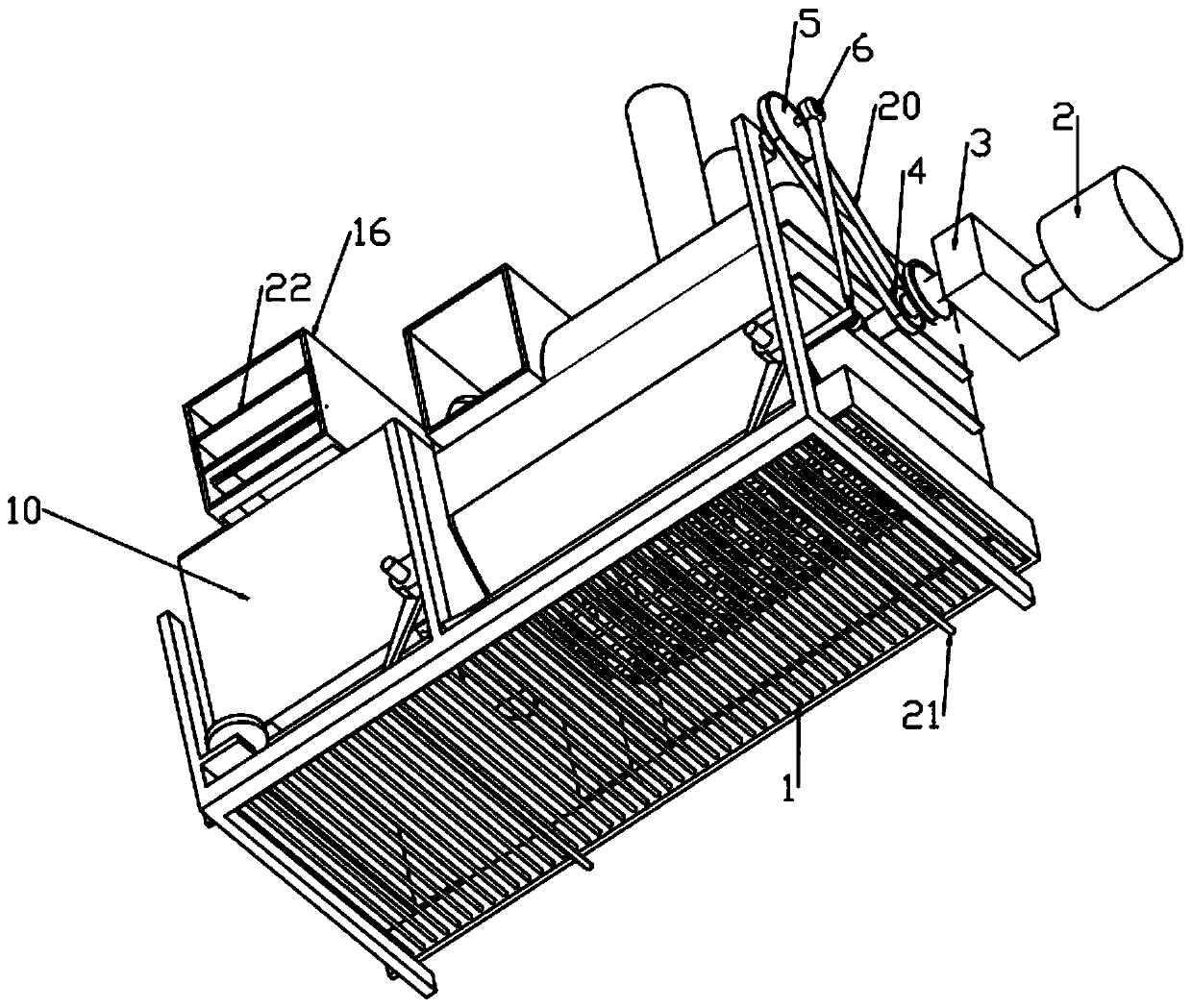

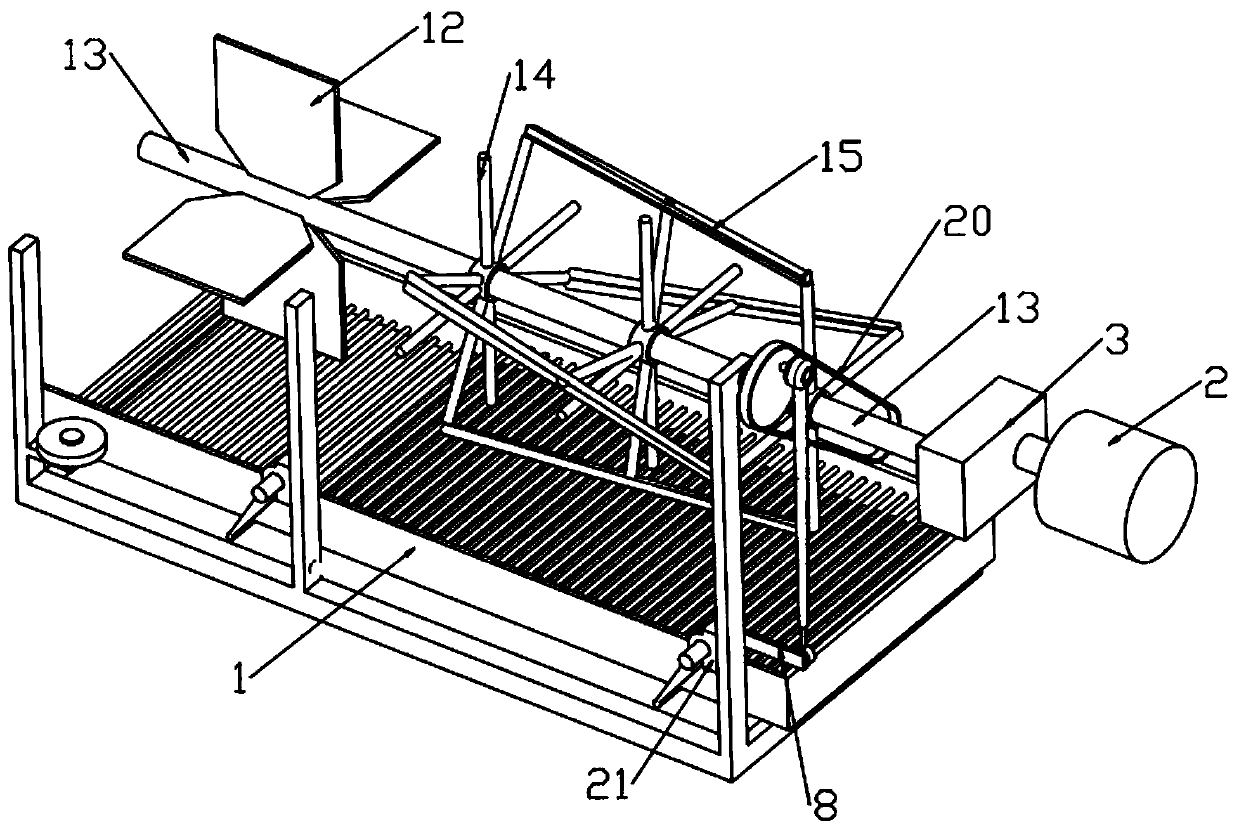

[0021] combined with Figure 1-Figure 4 , a vibration screening machine, comprising a mixing bin 11, a frame 19 arranged below the mixing bin 11, a sieve plate 1 is arranged between the mixing bin 11 and the base of the frame 19, one side of the mixing bin 11 is connected to the drum The air chamber 10 is fixedly connected, and the mixing chamber 11 is provided with a driving machine 2 on the side away from the blast chamber 10, and the output shaft of the driving machine 2 is axially connected with the driving wheel 4 through the gearbox 2, and the driving wheel 4 is in addition One end is connected with a drive shaft 13, and the end of the drive shaft 13 away from the driving wheel 4 runs through the mixing chamber 11 and the blast chamber 10 in turn;

[0022] The frame 19 is provided with a driven wheel 4 on the upper part of the side column near the driving wheel 4, and the driving wheel 5 and the driven wheel 4 are power connected through a transmission belt 20, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com