Auxiliary calibration device and method for tail end pose of mechanical arm

A calibration device and pose calibration technology, applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high manipulator operation requirements, lack of universal applicability, and long time-consuming, and achieve low operation difficulty and calibration The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

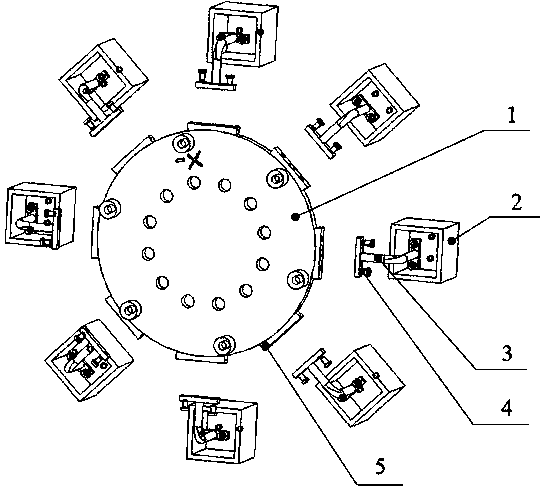

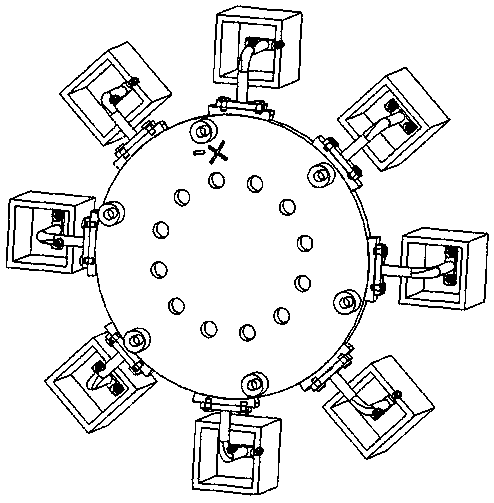

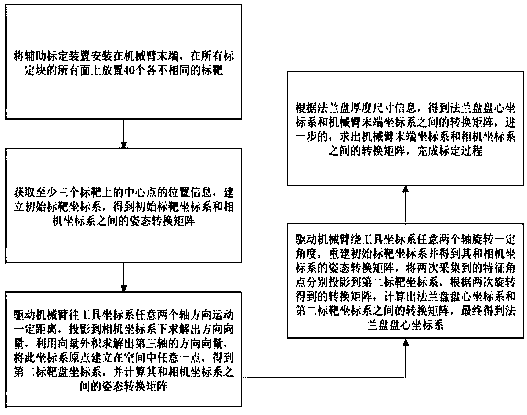

[0029]An auxiliary calibration device for the position and posture of the end of the mechanical arm in this embodiment is characterized in that it includes a flange 1, a calibration regular polyhedron 2 and a connecting rod 3, the center of the disk on one side of the flange 1 and the industrial mechanical arm The end effector is fixedly connected, and there are multiple calibration regular polyhedrons 2. The calibration regular polyhedron 2 is fixed on the outer side of the peripheral surface of the flange 1 through the connecting rod 3, except for the side connecting the calibration regular polyhedron 2 and the connecting rod 3, and the other surfaces Target paper is attached to each surface, and the codes of each target paper are different. The target paper is located within the visual range of the calibration vision equipment at the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com