Method for hard overhead construction of frame culvert of existing railway

A technology for existing railways and frame culverts, which is applied in the field of open-cut and cast-in-place construction of frame bridges passing through existing railways, can solve problems such as non-formation, and achieve the effects of saving construction costs, reducing overhead spans, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The construction method of the present invention will be described in more detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

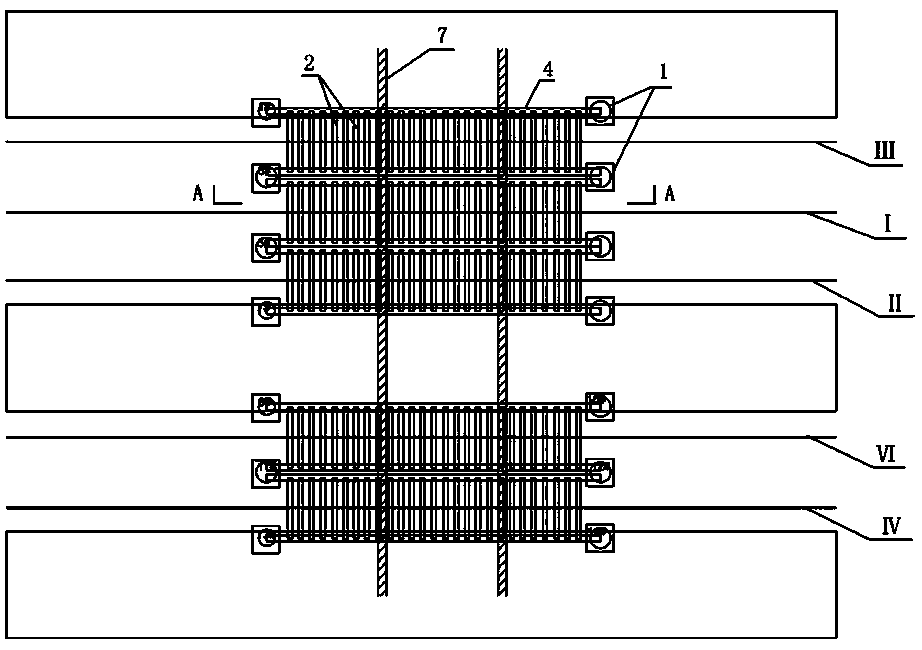

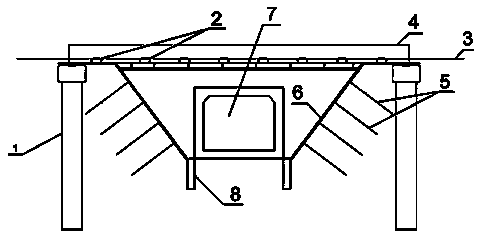

[0021] like figure 1 As shown, the present invention is to construct frame culverts under the existing lines of five roads (Ⅰ, Ⅱ, Ⅲ, Ⅵ, Ⅳ). After detection, the soil quality at this place is Class 1 or 2, and the stability is relatively poor. Slope support measures are required.

[0022] The method of existing railway hard overhead construction frame culvert described in the present invention, its construction steps are as follows:

[0023] In the first step, two rows of fulcrum bored piles 1 are arranged symmetrically at both ends of the existing line design and reconstruction position. A total of 14 fulcrum bored piles need to be laid out. The depth of the bored piles is not less than twice the depth of the foundation pit to be excavated. like figure 1 shown;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com