Novel geological stacked hole reamer

A hole reamer and geological technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc., can solve the problems of high equipment cost, inconvenient portability, and non-adjustable size, and achieve uniform water spraying of water holes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

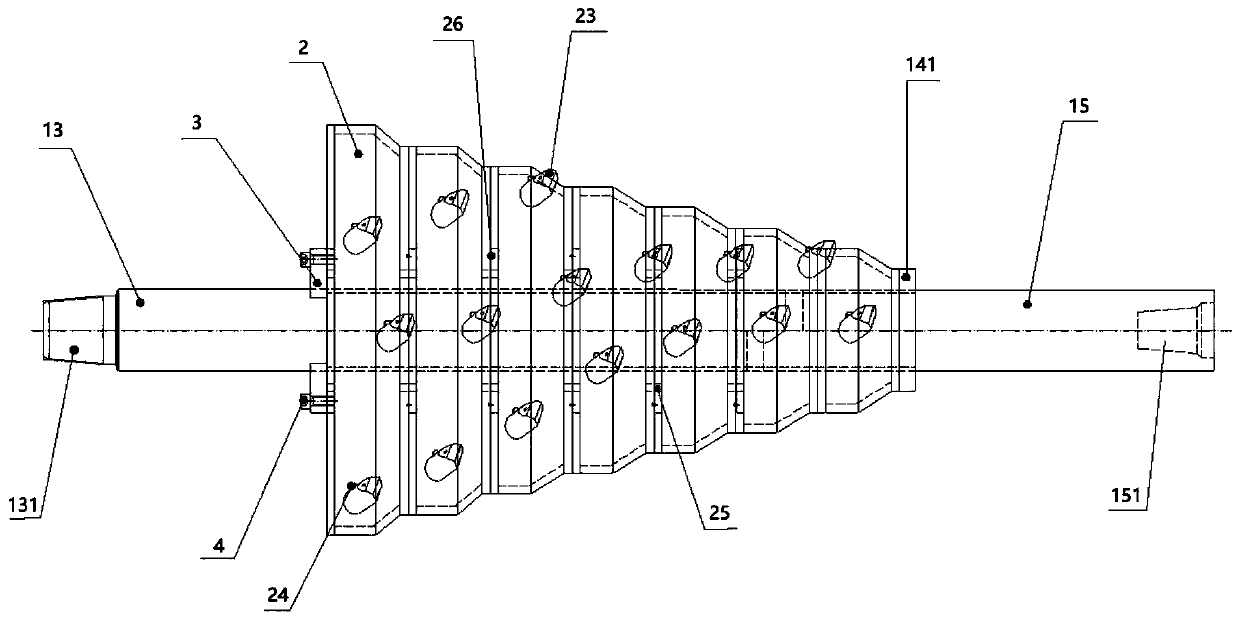

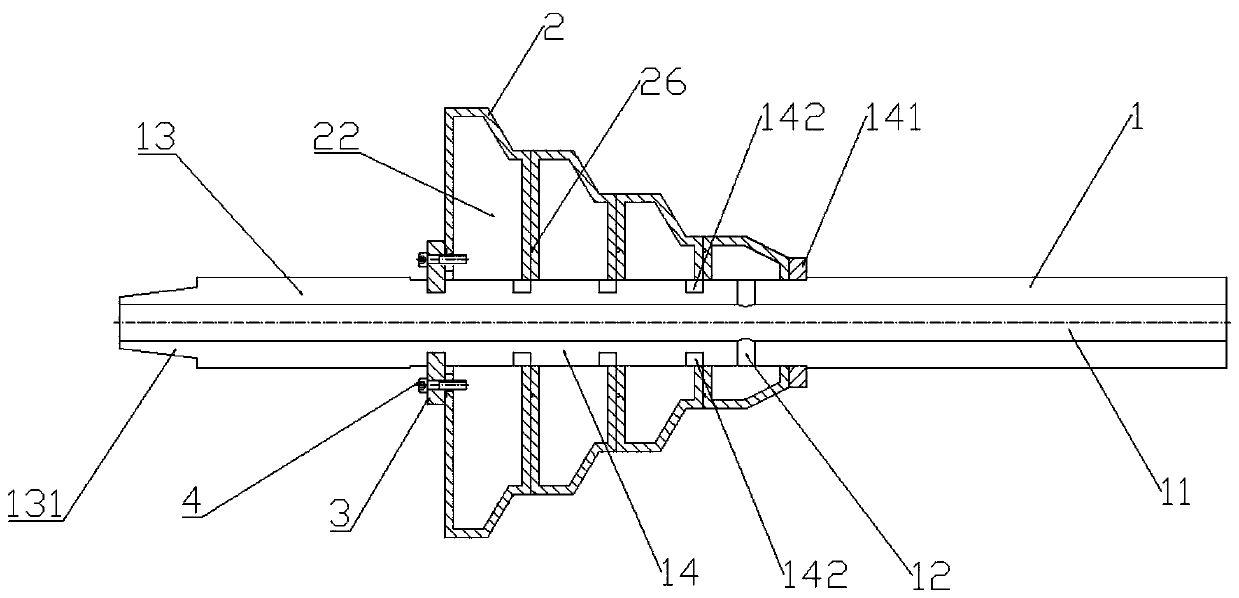

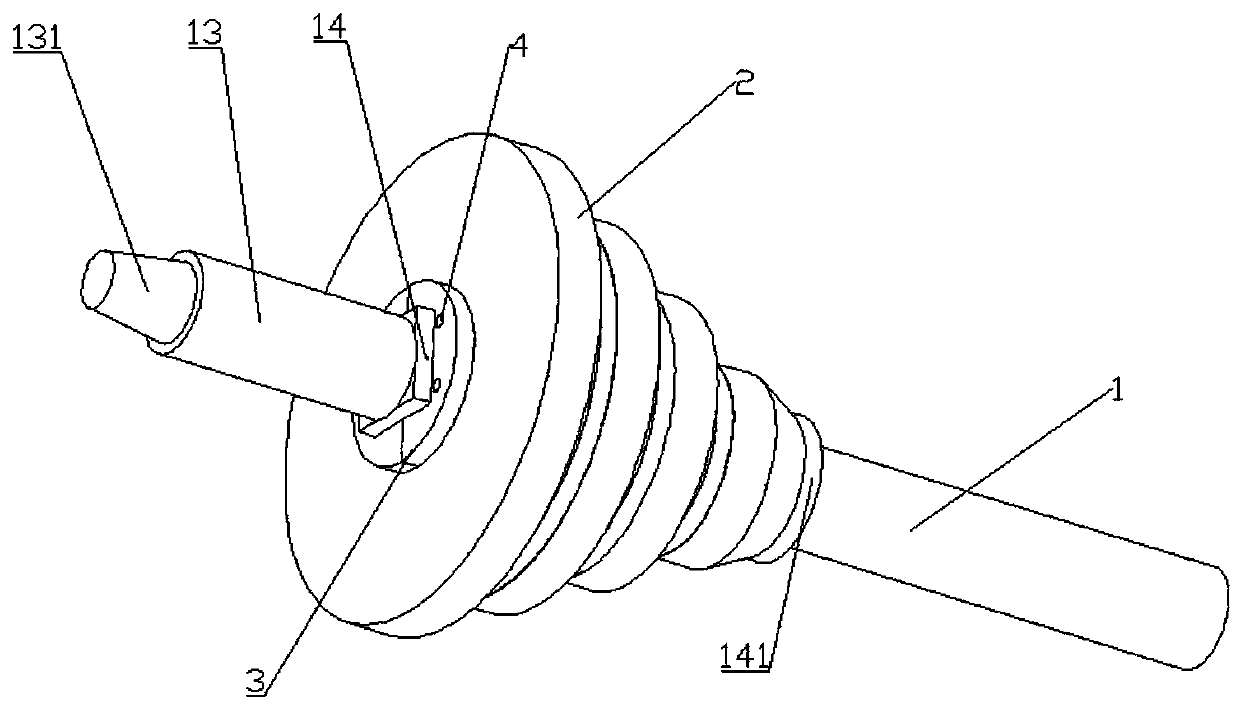

[0039] see Figure 1 to Figure 8 , figure 1 It is the structural representation of the split-stack reamer of the present embodiment; figure 2 It is a schematic cross-sectional structure diagram of the stacked reamer of the present embodiment; image 3 It is a schematic diagram of the three-dimensional structure of the stacked reamer of the present embodiment; Figure 4 is the structural representation of the connecting rod in this embodiment; Figure 5 is a schematic cross-sectional view of the connecting rod in this embodiment; Figure 6 is a schematic structural diagram of the limiting block in this embodiment; Figure 7 It is a structural schematic diagram of the tower block of the present embodiment; Figure 8 It is the installation diagram of the sub-stack reamer in this embodiment.

[0040] Such as Figure 1 to Figure 3 As shown, a new type of geological split reamer in this embodiment includes a connecting rod 1, a limit block 3 and a plurality of tower blocks 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com