Control system and control method applied to hydraulic variable valves

A control system and variable technology, applied in the direction of valve device, machine/engine, mechanical equipment, etc., can solve the problems of engine output increase and disadvantage, achieve the effect of reducing friction, reducing cost and improving fuel mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

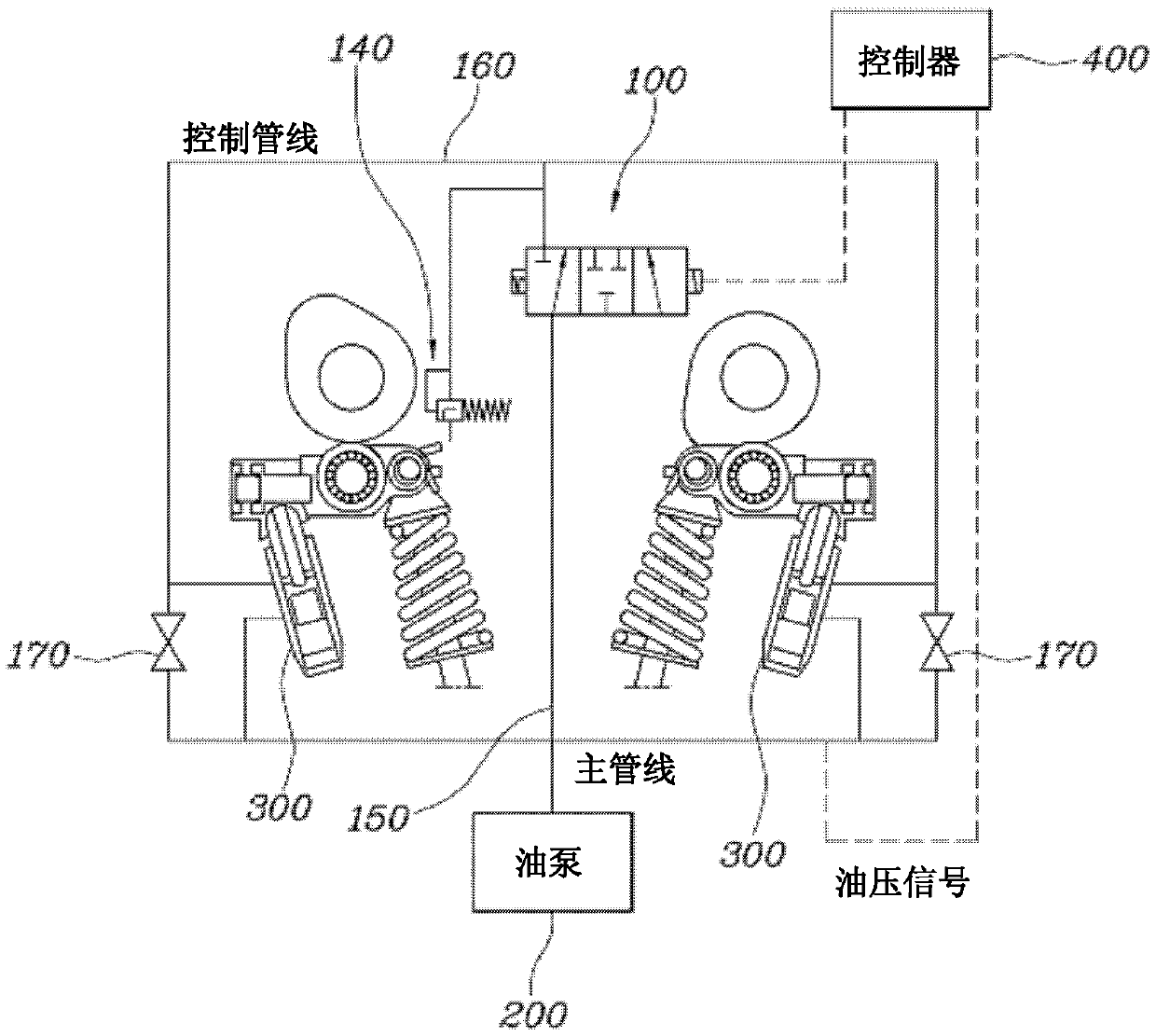

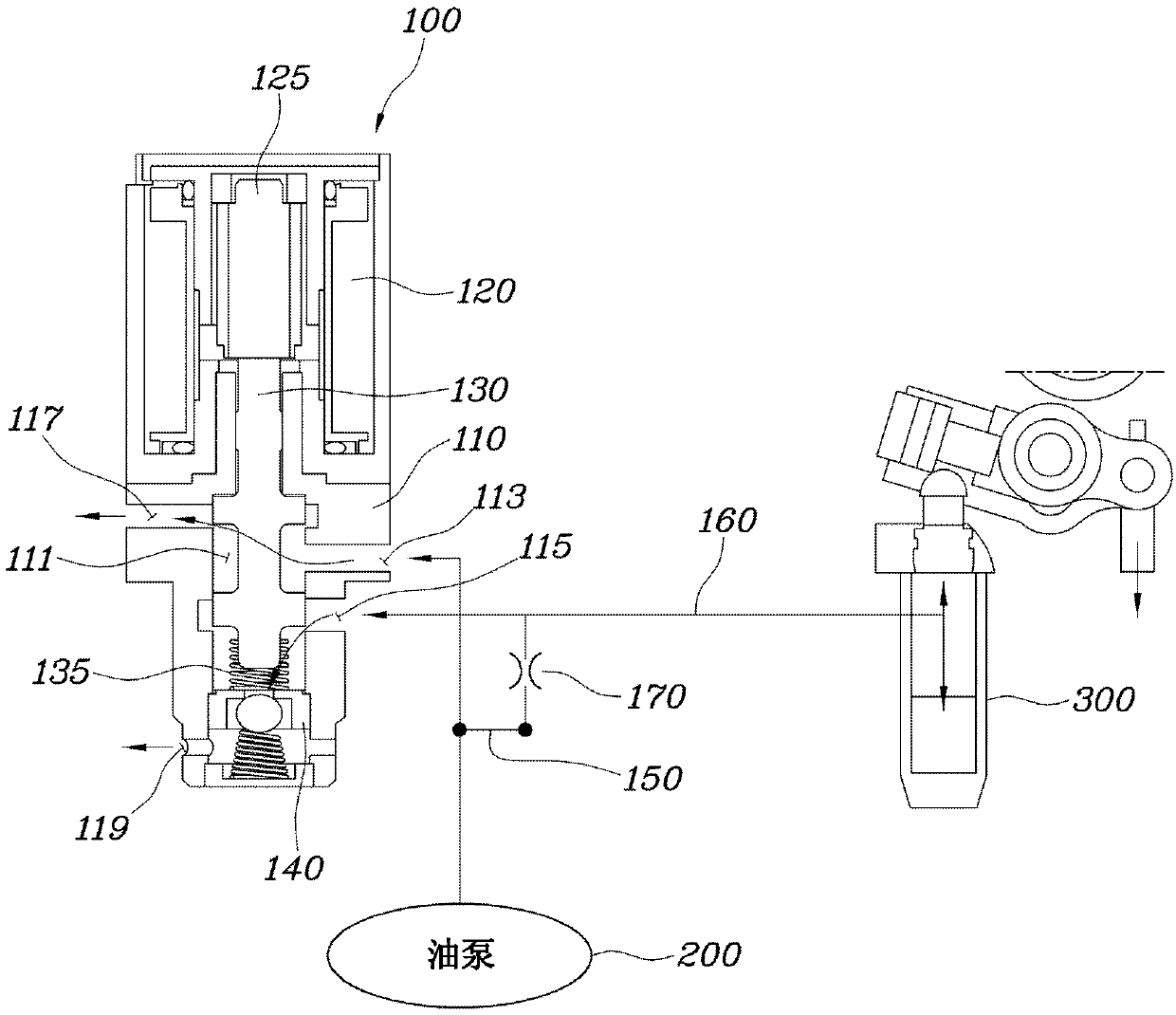

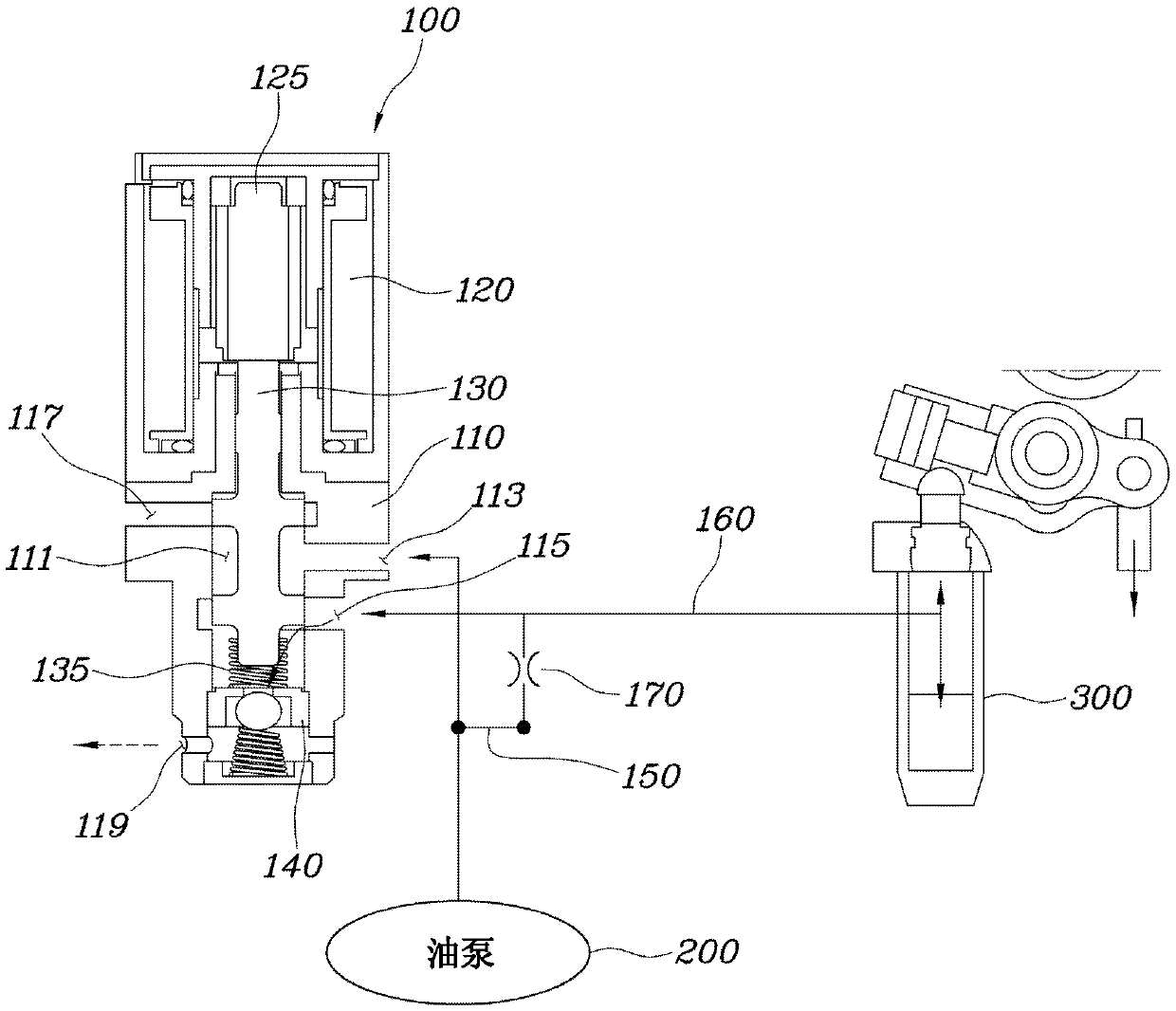

[0039] figure 1 is a block diagram schematically showing a control system for a hydraulically variable valve according to one form of the present disclosure, and Figure 2 to Figure 4 is a view showing oil flow and operation according to each control mode of the control system for a hydraulic variable valve according to the present disclosure.

[0040] refer to Figure 1 to Figure 4 , the control system for a hydraulic variable valve according to the present disclosure may include: an oil control valve (OCV) 100 configured with: a housing 110 in which a flow passage 111 is defined, provided on an outer peripheral surface of the housing 110 and The main port 113 that allows the flow passage 111 and the oil pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com