Tufted carpet comprising polyethylene glycol terephthalate bulked continuous filaments

A technology of ethylene glycol phthalate and tufted carpets, which is applied in the field of tufted carpets, can solve the problems of reduced yarn volume, low appearance quality, and low quality, and achieve increased volume, improved appearance, and volume. The effect of abrasion resistance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

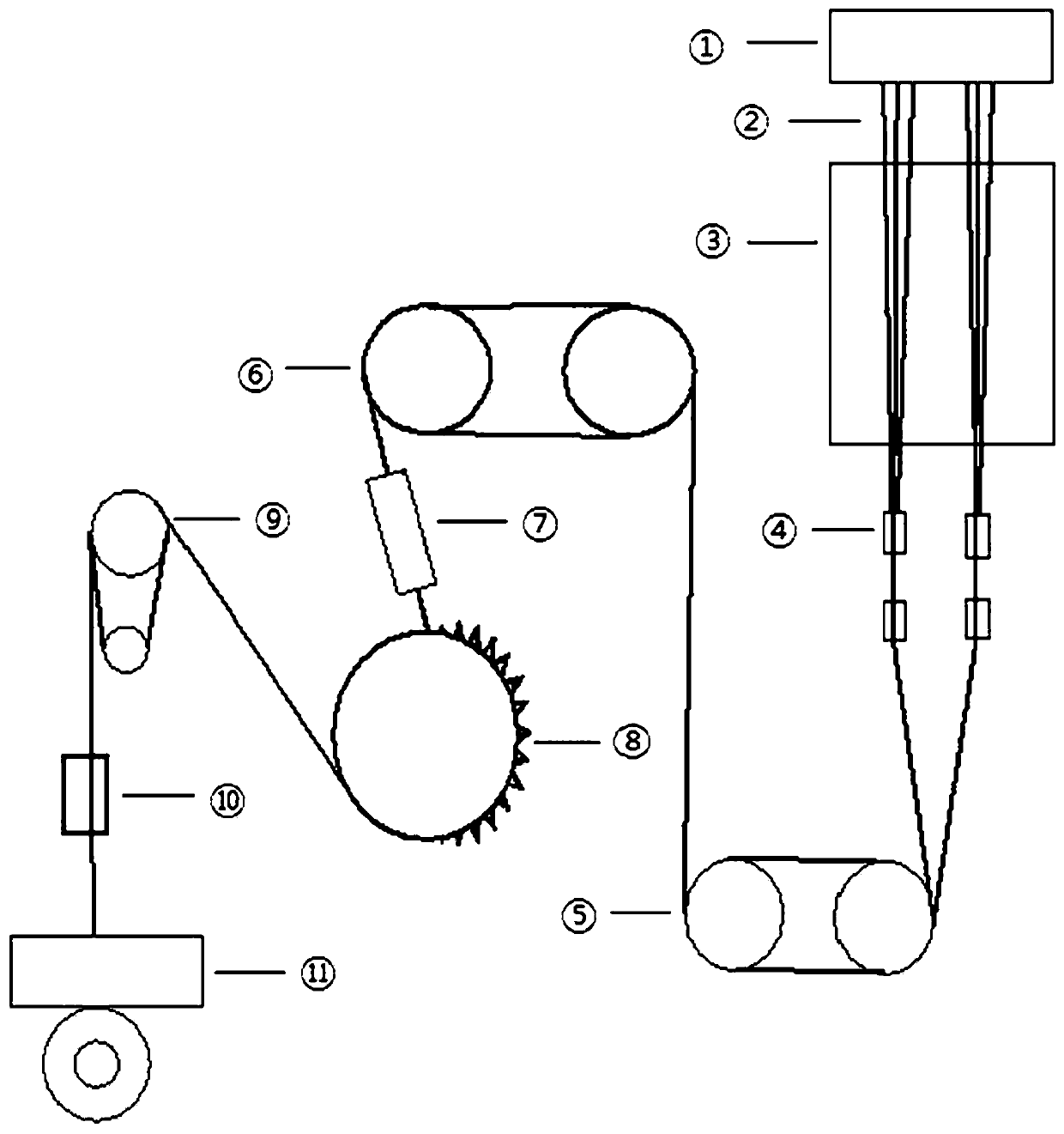

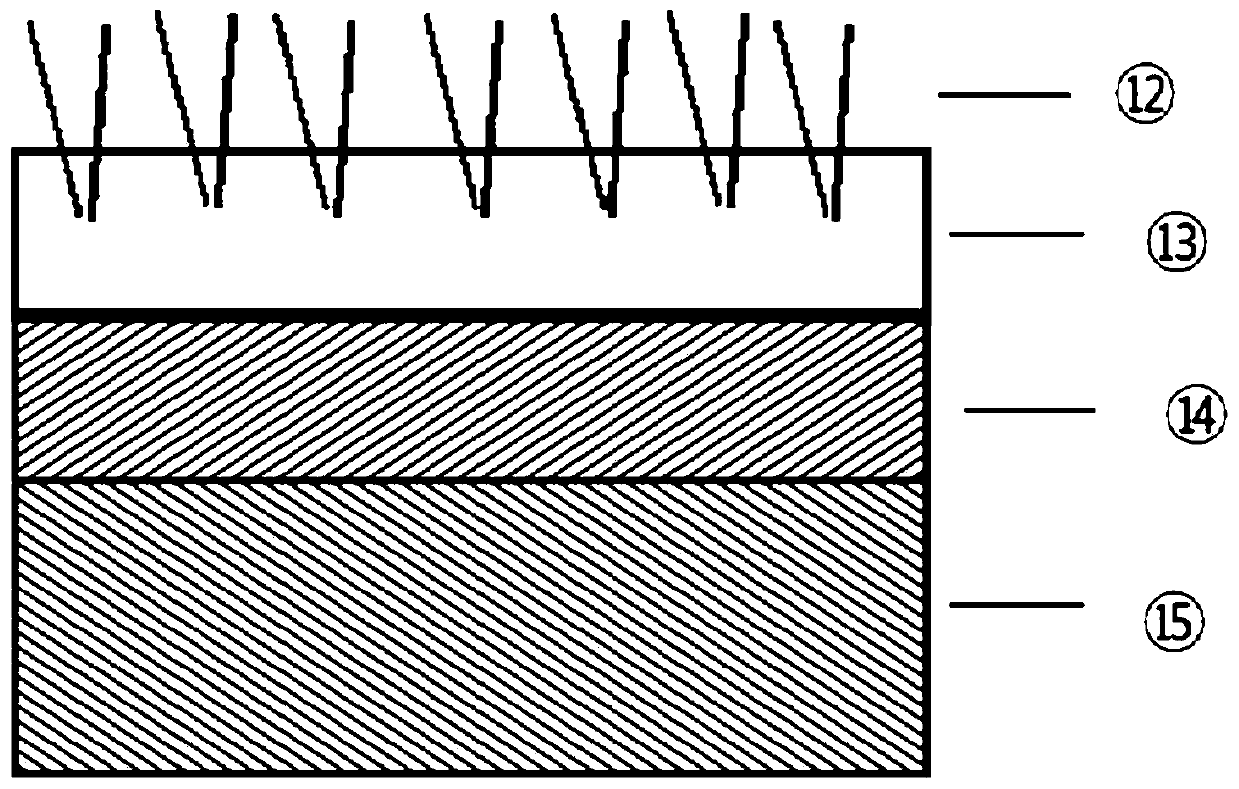

Method used

Image

Examples

Embodiment 1

[0050] A slurry prepared by mixing 50 parts by weight of ethylene glycol and 100 parts by weight of terephthalic acid was added to an esterification reactor and pressurized at 250° C. under a pressure of 0.5 Torr for 4 hours, so that water flowed out of the reactor and the esterification The reaction proceeds, thereby producing (2-hydroxyethyl)terephthalate. At this point, 300 ppm of phosphorus heat stabilizer was added at the end of the esterification reaction. After the esterification reaction, 300 ppm of an antimony catalyst was added as a polymerization catalyst at the beginning of the polycondensation reaction, and the temperature was increased from 250°C to 285°C at 60°C / hr, and the pressure was reduced to 0.5 Torr. Solid phase polymerization is performed to increase the viscosity of the liquid polymer. Typically a batch solid phase polymerizer is used during the solid phase polymerisation process to dry under vacuum at 140°C for 4 hours. The temperature was increased ...

Embodiment 2 and 3

[0053] The polyethylene terephthalate BCF yarn was prepared by the same procedure as in Example 1, except that the yarn was rapidly made at the outlet of the texturing nozzle with cooling air or cooling water at the temperature and pressure shown in Table 1 below. cool down.

Embodiment 4

[0055] A polyethylene terephthalate BCF yarn was prepared by the same procedure as in Example 1, except that the yarn was cooled by sucking air through a cooling drum placed within 1 cm slightly below the texturing nozzle to quench the air, whereas Instead of cooling the yarn with cooling air at the exit of the texturing nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com