Heating control method for cooking equipment and cooking equipment

A technology for heating control and cooking equipment, applied in the field of kitchen appliances, can solve the problems of reducing the service life of electric cookers, affecting user experience, poor food taste, etc., to achieve the effect of improving experience, simple and easy detection methods, and ensuring taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

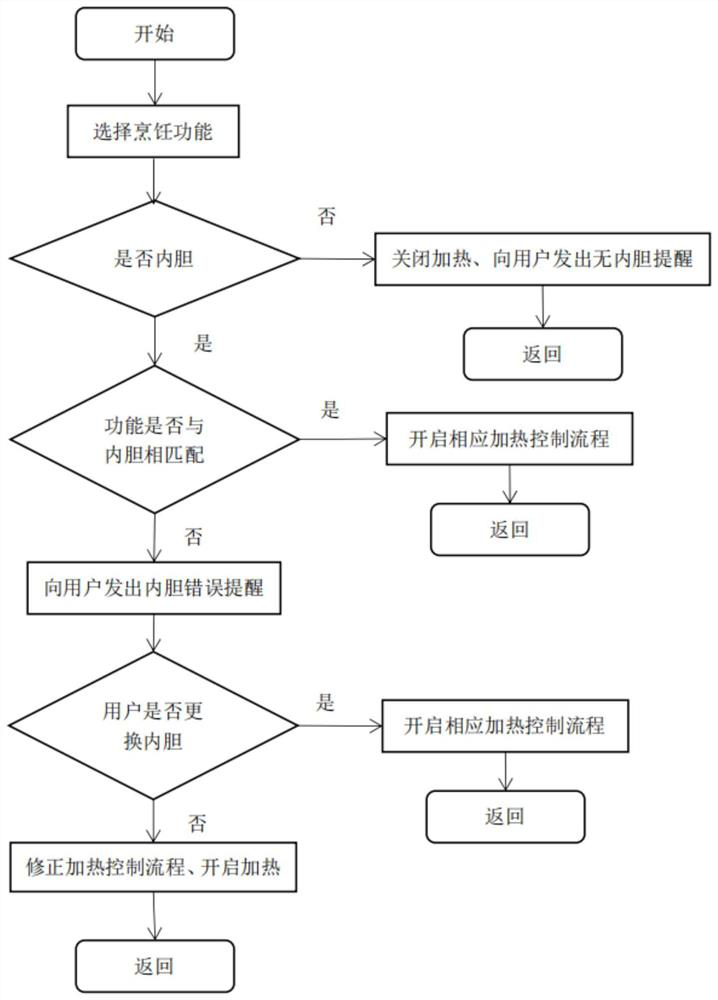

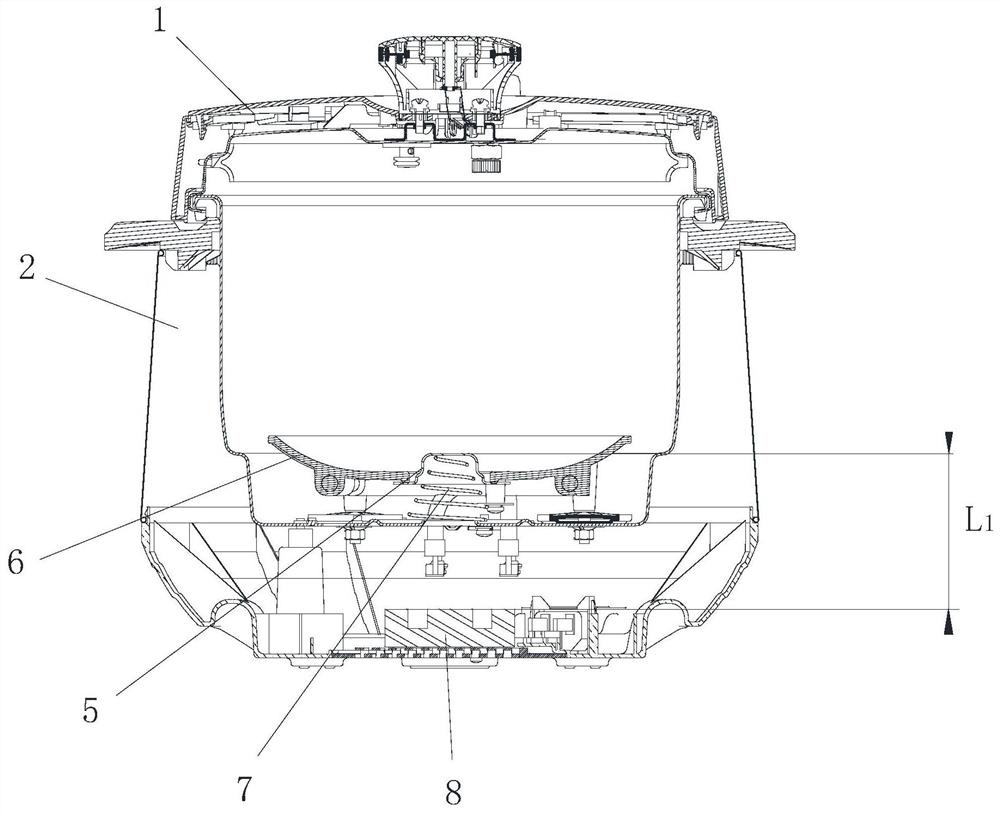

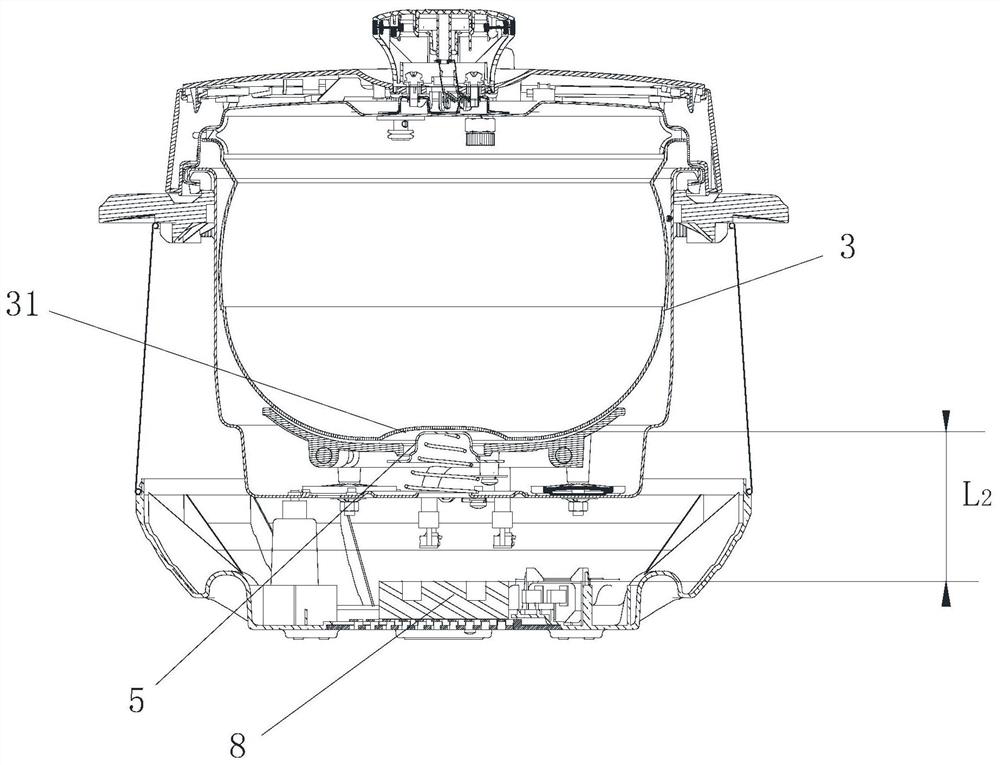

[0064] Embodiment 1: A heating plate 6 is arranged inside the pot body 2, and the bottom of each inner container has a support surface that abuts against the heating plate 6 for support, and the central part of the bottom of each inner container The distance from its own supporting surface is different; the center of the heating plate 6 is provided with a through hole, and the temperature measuring sensor 5 and the elastic member 7 connected with the temperature measuring sensor 5 are also arranged in the described pot body 2, so The temperature measuring sensor 5 can expand and contract along the through hole under the joint action of the elastic member 7 and the inner container; a distance measuring sensor 8 is also arranged in the pot body 2, and the distance measuring sensor 8 is used Measure the distance between the temperature measuring sensor 5 and the distance measuring sensor 8; the heating control method judges whether there is a liner in the pot body 2 through the di...

Embodiment approach 2

[0069]Embodiment 2: There are two kinds of inner pots, one of which is provided with magnetic parts, and the other is made of non-magnetic materials; A detection element of a magnetic field; the heating control method identifies the type of the liner through the signal detected by the detection element.

[0070] In the following, one of the inner pots is an aluminum non-stick pot inner pot 3, the other is a stainless steel inner pot 4 and it is provided with the magnetic parts, and the detection element is a reed switch or a Hall element as an example. This embodiment will be further described in detail.

[0071] As preferably, the detection element is arranged on the lid 1 of the cooking equipment, the magnetic part is arranged on the edge of the stainless steel liner 4, and the location of the magnetic part and the detection element should be In this way, when the lid 1 is closed to the body 2, the magnetic field generated by the magnetic member can act on the reed switch o...

Embodiment approach

[0074] In this embodiment, the cooking equipment further includes a micro switch. The micro switch is an external mechanical force acting on the action reed of the micro switch through the transmission element of the micro switch, so that the fixed contact at the end and the moving contact Point the switch for quick on or off. When the liner is placed on the pot body 2, the contact of the micro switch can be against the liner; the heating control method judges that there is Without liner. Preferably, the micro switch is arranged on the pot cover 1, and the upper edge of the liner is in a closed ring shape, and the position of the micro switch on the pot cover 1 makes the When the pot body 2 is closed and the liner is placed in the pot body 2, the transmission element of the micro switch can touch the upper edge of the liner and trigger the action reed action, thus it can be determined that there is an inner container in the pot body 2 . When the user forgets to put the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com