Nuclear power plant shellfish catcher and fluid filtering method thereof

A technology of traps and nuclear power plants, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problem that it is difficult to deal with a large number of impurities entering the shellfish trap at the same time, the processing capacity per unit time is small, and the backwashing of the mesh surface is difficult. Small and other problems, to achieve the effect of strong backwashing ability, guaranteed usability, and large filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

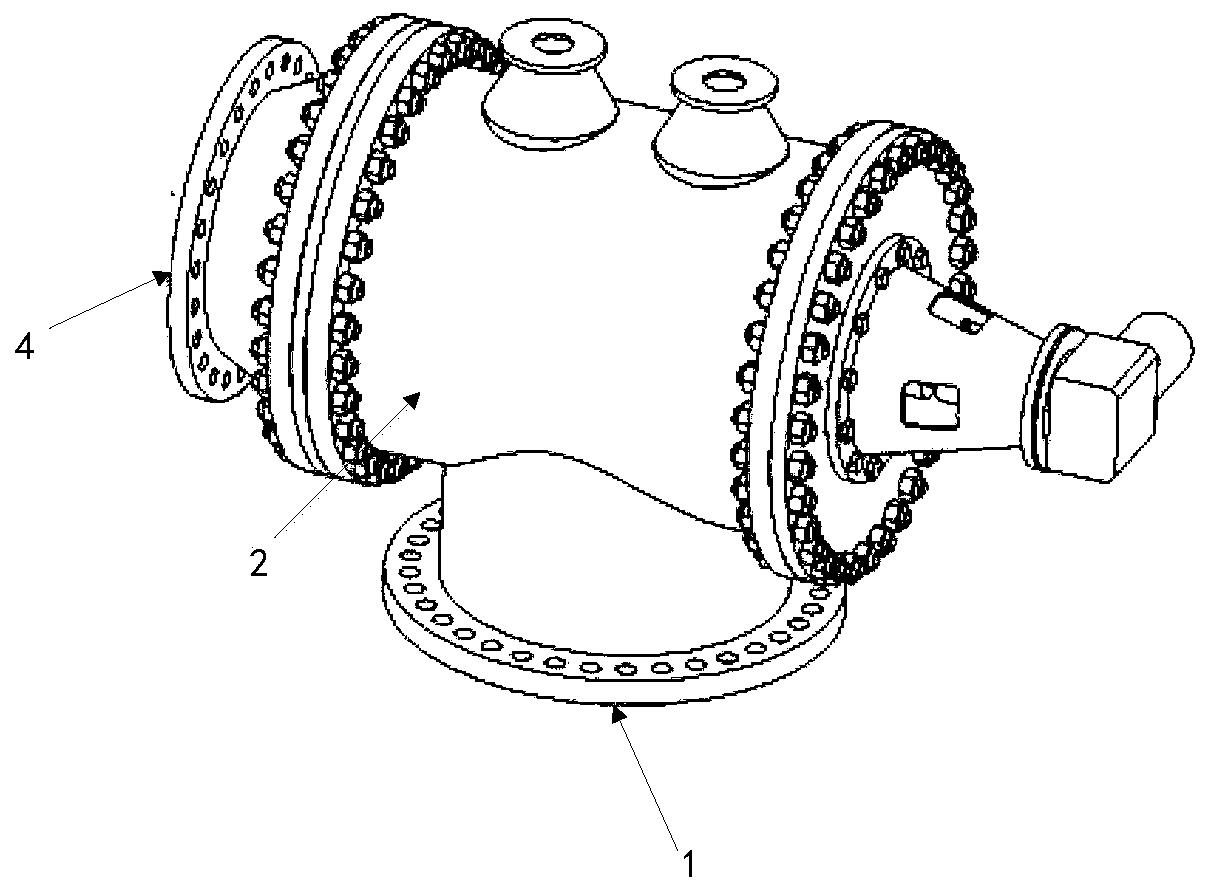

[0032] The invention provides a nuclear power plant shellfish catcher, such as figure 1 As shown, the nuclear power plant shellfish trap consists of:

[0033] The fluid inlet port 1 is used for the entry of sea water;

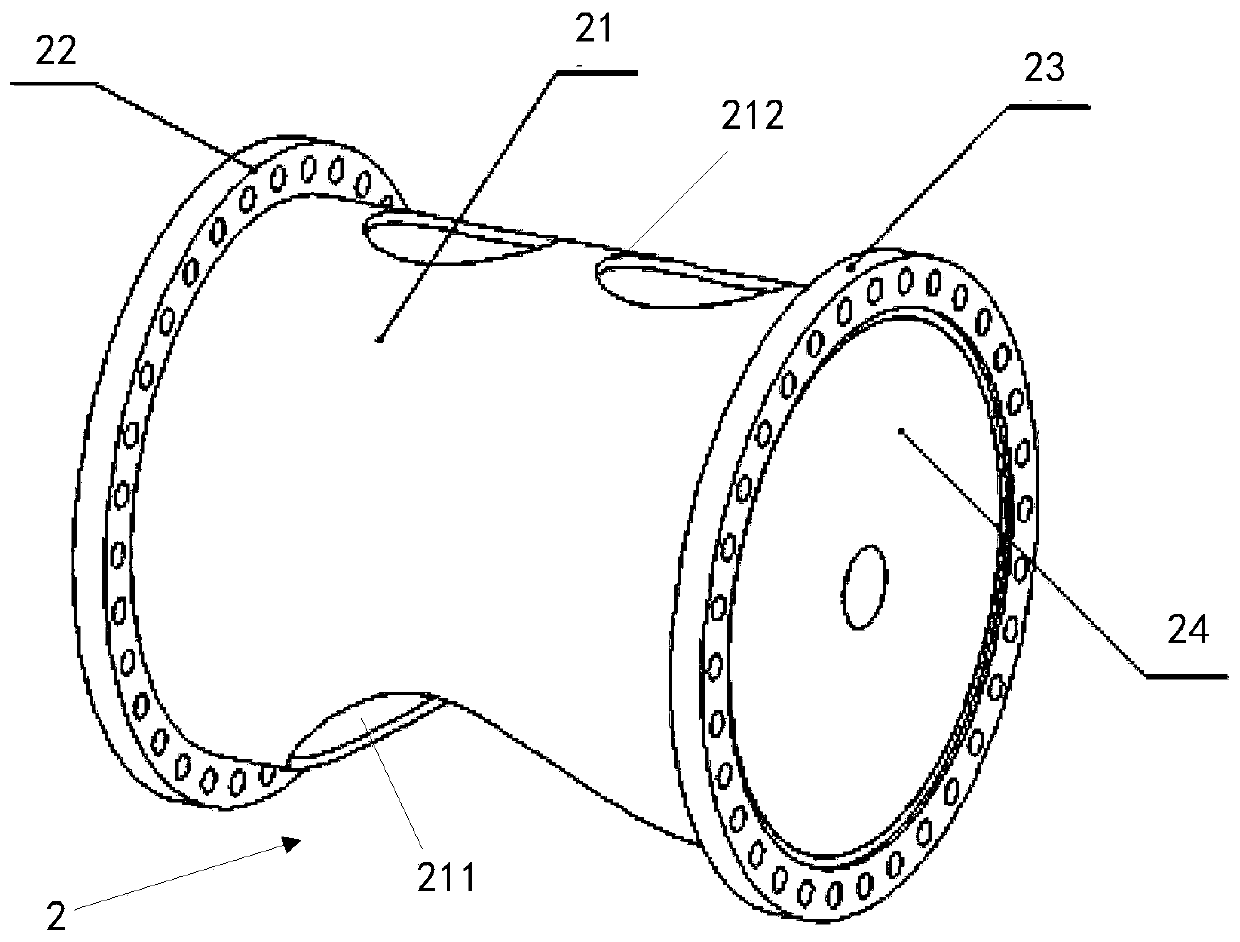

[0034] The cylinder body 2 is fixedly connected with the fluid inlet port 1, and is used to form a fluid channel to accommodate seawater;

[0035] The fluid outlet port 4 is fixedly connected to the cylinder body 2 and is perpendicular to the fluid inlet port 1 for the filtered seawater to flow out;

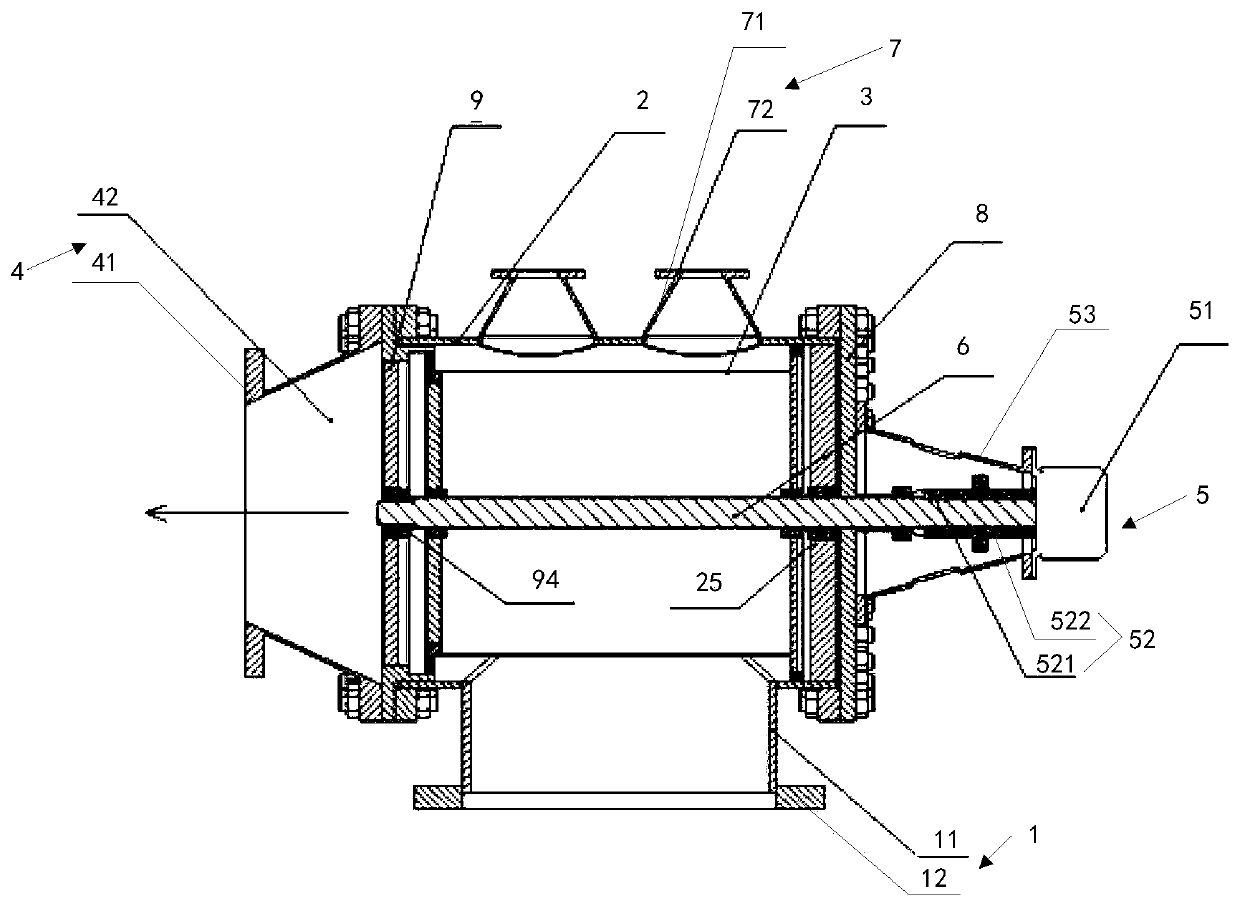

[0036] Further, as figure 2 As shown, the nuclear power plant shellfish trap also includes:

[0037] The filter cartridge 3 is arranged inside the cylinder body 2 for filtering seawater;

[0038] The power assembly 5 is fixedly connected with the cylinder body 2, and is used to provide rotational driving force through its rotating shaft in the backwashing mode of the filter cartridge;

[0039]The rotating shaft 6 is fixedly connected to the rotating shaft of...

Embodiment 2

[0072] The present invention also provides a fluid filtration method for shellfish traps in nuclear power plants, which is suitable for the shellfish traps in nuclear power plants in Embodiment 1, such as Figure 11 As shown, the fluid filtration method includes:

[0073]Step S1, judging whether the shellfish trap of the nuclear power plant is in the normal filtering mode or the filter cartridge backwashing mode;

[0074] Step S2. If it is in the normal filtering mode, close the connection between the cylinder body 2 and the backwash nozzle 7, the seawater enters the cylinder body 2 from the fluid inlet port 1, and enters the inside of the filter cartridge 3, and the filtered seawater moves along the axis of the filter cartridge 3 To flow, from the fluid outlet port 4 to flow out of the nuclear power plant shellfish trap; preferably, the connection between the cylinder body 2 and the backwash nozzle 7 can be closed by closing the valve between the cylinder body 2 and the backw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com