Microporous plate dust removal structure on dry desulfurization and denitrification equipment

A dry desulfurization, micro-plate technology, applied in separation methods, chemical instruments and methods, nitrous oxide capture, etc., can solve the problems of increased investment, large floor space, and insufficiently low export dust content. Improve dust removal efficiency, reduce equipment costs, and improve the effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

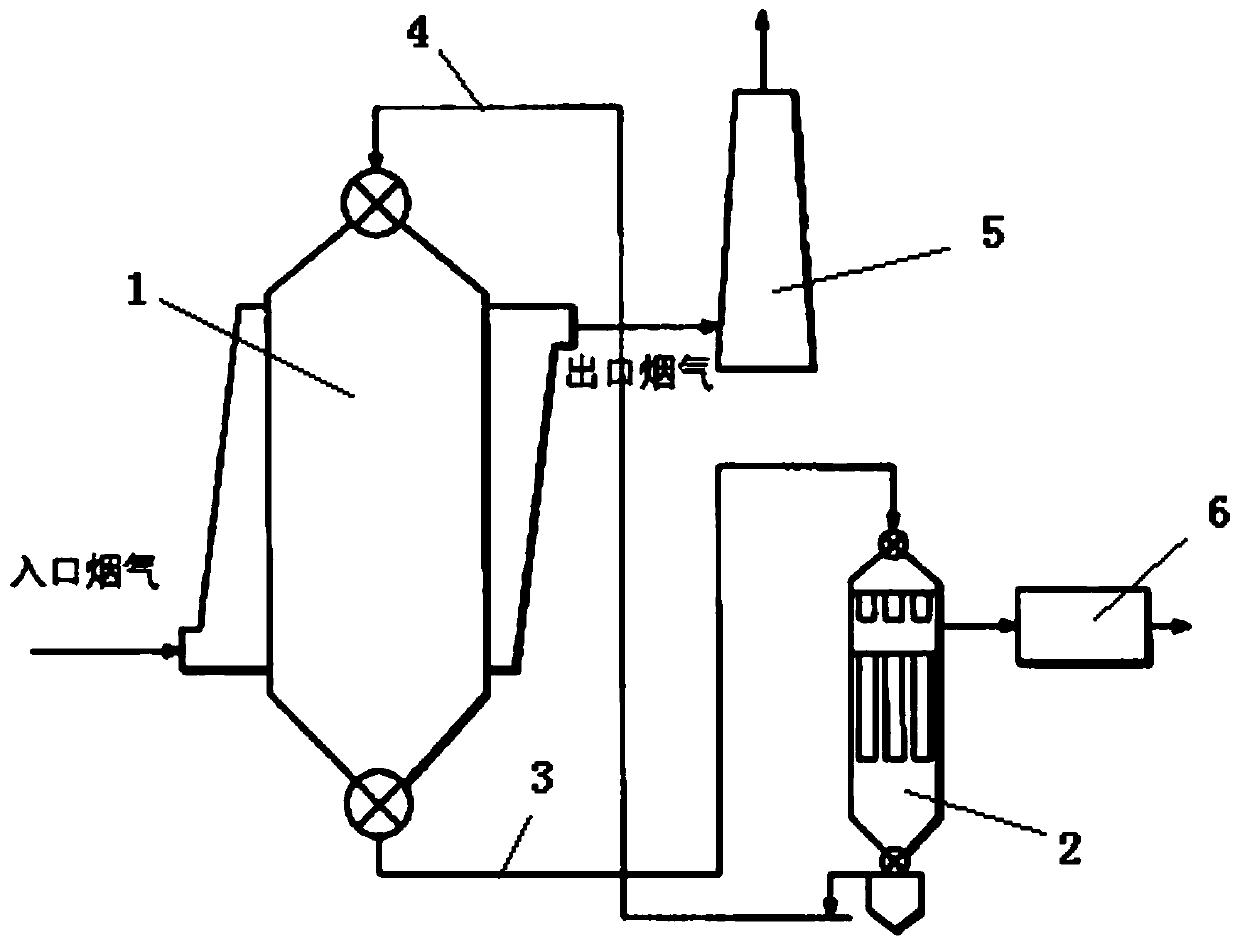

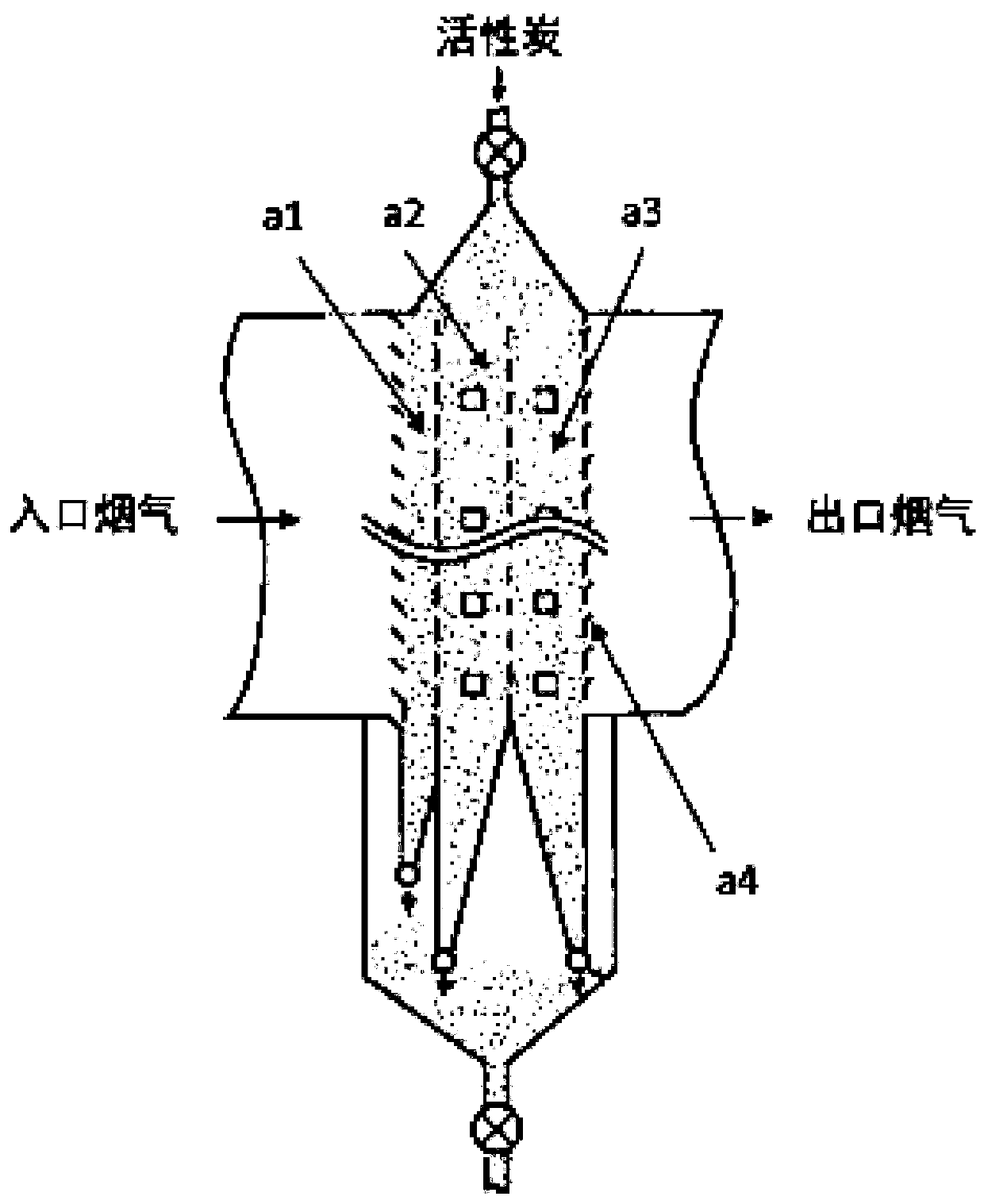

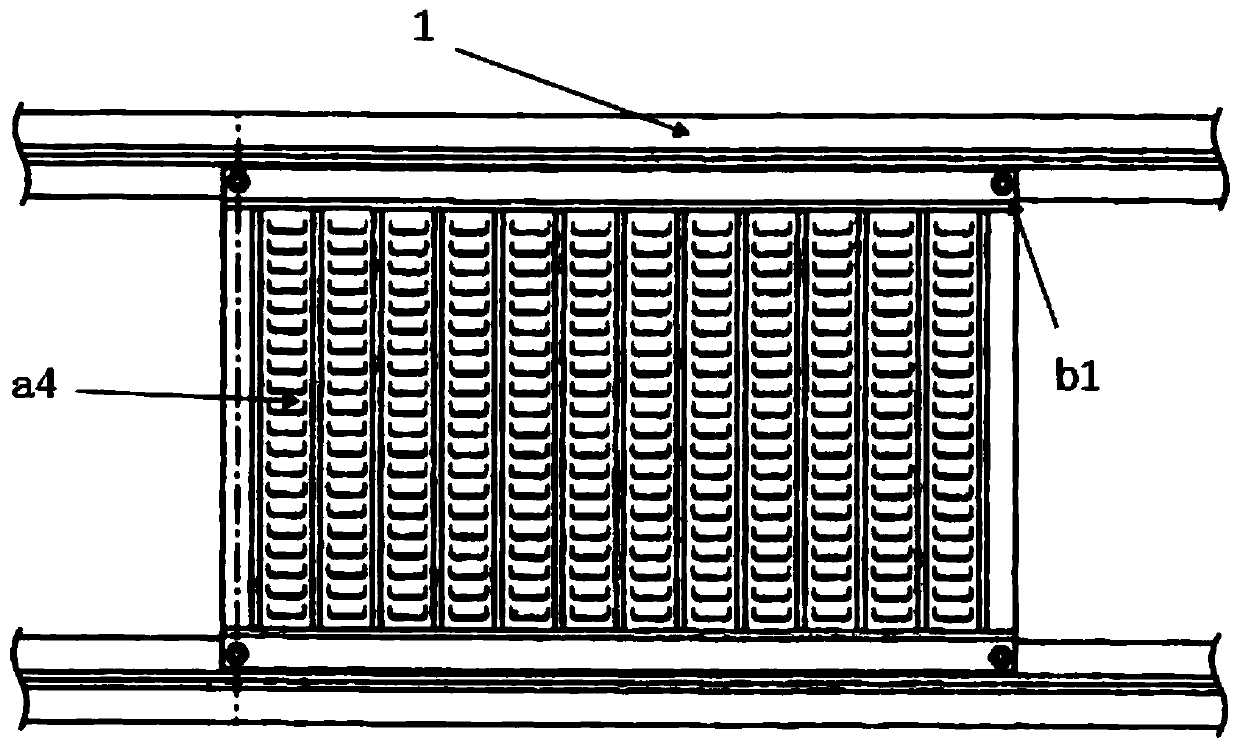

[0022] like Figure 1-5 As shown, the microporous plate dust removal structure on the dry desulfurization and denitrification equipment includes adsorption tower 1 and desorption tower 2. The bottom of the adsorption tower 1 is provided with a flue gas inlet, and the top is provided with a horizontal flue gas outlet. The adsorption tower 1 is provided with a front chamber a1, a middle chamber a2 and a rear chamber a3. Between the front chamber a1 and the middle chamber a2, and between the middle chamber a2 and the rear chamber a3, there are perforated plates, and between the rear chamber and the flue gas outlet, a microperforated plate a4 is arranged. The analysis tower 2 includes a heating section arranged in the upper part of the analysis tower and a cooling section arranged in the lower part of the analysis tower. The lower end of the adsorption tower is connected to the upper end of the analysis tower through the chain bucket machine 3 of the analysis tower that transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com