Oil pump copper sleeve automatic press-fitting equipment

An oil pump and copper sleeve technology is applied in the field of automatic press-fitting equipment for oil pump copper sleeves, which can solve problems such as misplacement, and achieve the effect of ensuring installation position, small size and preventing scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

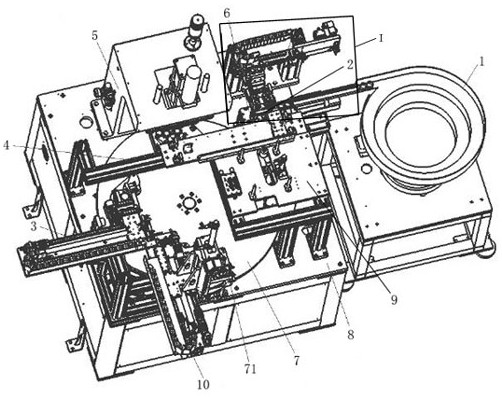

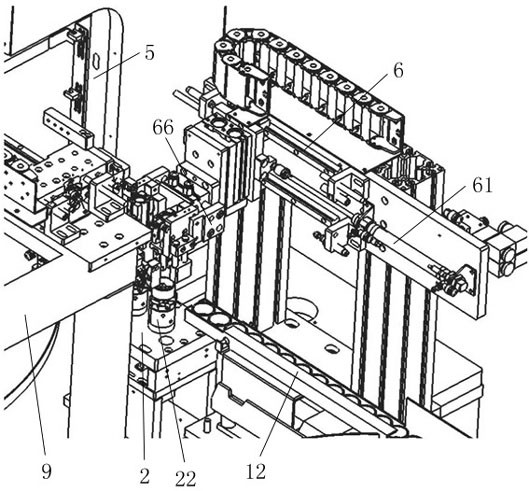

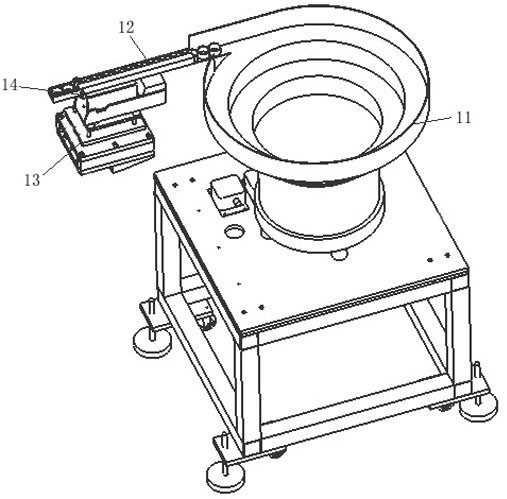

[0033] Such as figure 1 with figure 2 As shown, an automatic press-fitting equipment for copper sleeves of oil pumps, which includes a copper sleeve feeding mechanism 1, a copper sleeve gap identification mechanism 2, an end cover feeding mechanism 3, a copper sleeve unloading mechanism 4, and pressing the copper sleeve into the end The cover pressing mechanism 5, the transfer mechanism 6 that transfers the copper sleeve from the copper sleeve feeding mechanism to the copper sleeve gap identification mechanism, and the turntable mechanism 7 that undertakes the material transfer during the entire pressing process, all of the above mechanisms are installed on a workbench 8 On the top, a plurality of end cap positioning fixtures 71 are installed on the turntable mechanism 7, and the number of copper sleeves transferred by the transfer mechanism 7 is two at a time. The feeding mechanism 4 is used to transfer the two copper sleeves on the copper sleeve gap identification mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com