Tooling and method for removing burrs from aero-engine fuel injectors using abrasive flow technology

A technology for aero-engines and fuel injectors, applied in the aerospace field, can solve problems such as abrasive particle flow cannot remove burrs well, achieve the effects of improving efficiency and consistency, improving surface finish, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

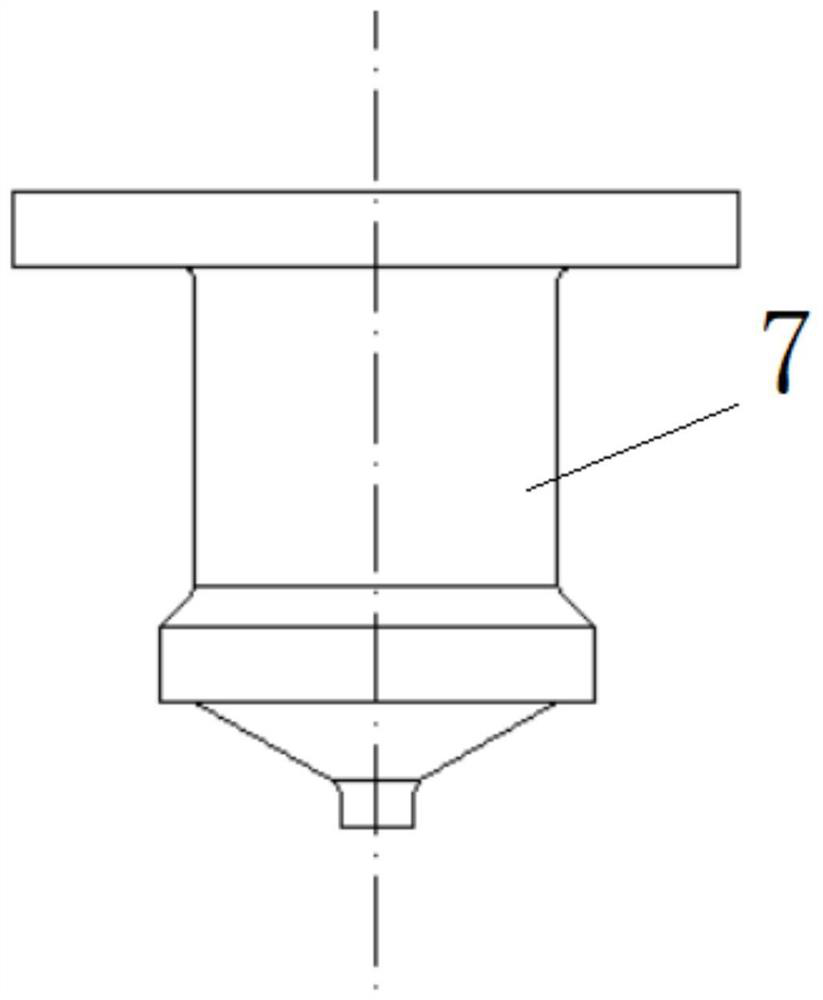

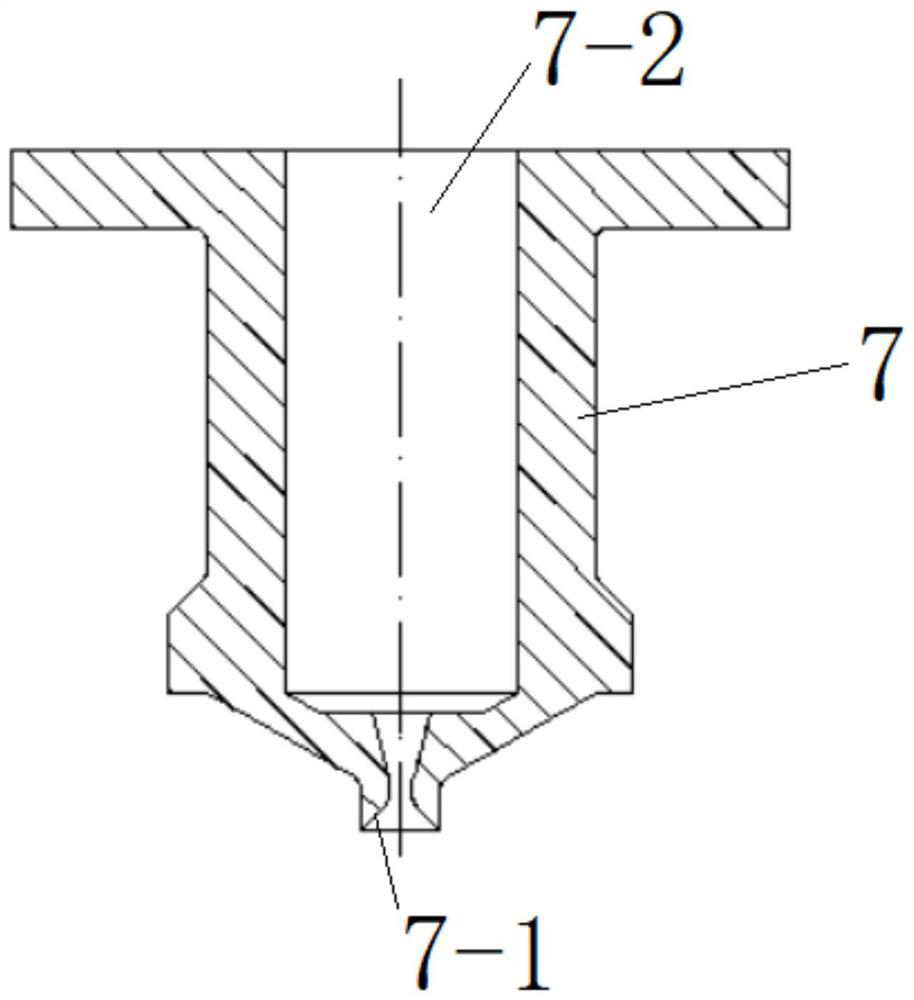

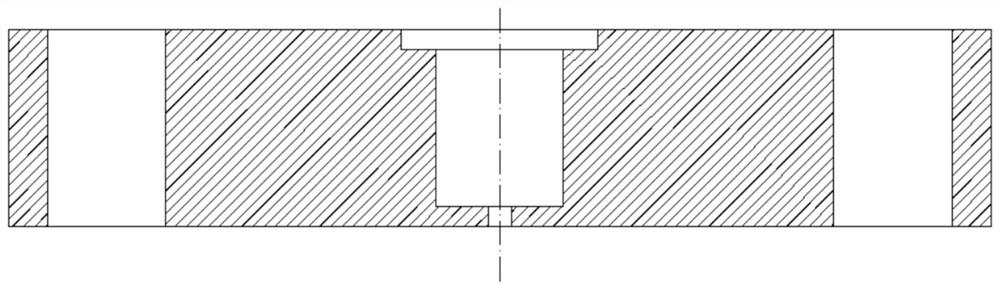

[0050] Such as Figure 6(a) ~ Figure 6(c) , Figure 7(a) ~ Figure 7(c) as well as Figure 8 As shown, in this embodiment, the tooling for removing burrs from aero-engine fuel injectors using the abrasive flow process adopts an upper and lower two-part structure, which are the upper fixture A and the lower fixture B respectively, wherein both the upper fixture A and the lower fixture B have two positioning The pin hole, the upper fixture A is made of nylon material, which is in soft contact with the upper surface of the fuel injector 7 to be processed, the cylinder boss 3 at the lower end of the upper fixture A can be inserted into the oil inlet at the upper end of the fuel injector 7, and the cylinder convex There is a seamless fit between platform 3 and the oil inlet of the fuel injector. The height of the cylindrical boss 3 is low. The cylindrical boss 3 can prevent the abrasive from flowing out in the gap between the fixture and the upper end of the fuel injector in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com