Drilling machine for integrated circuit board production

A technology of integrated circuit boards and drilling machines, which is applied in metal processing and other directions, can solve the problems of missing holes in circuit boards, wrong holes in circuit boards, damage, etc., and achieve the effect of solving circuit board damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

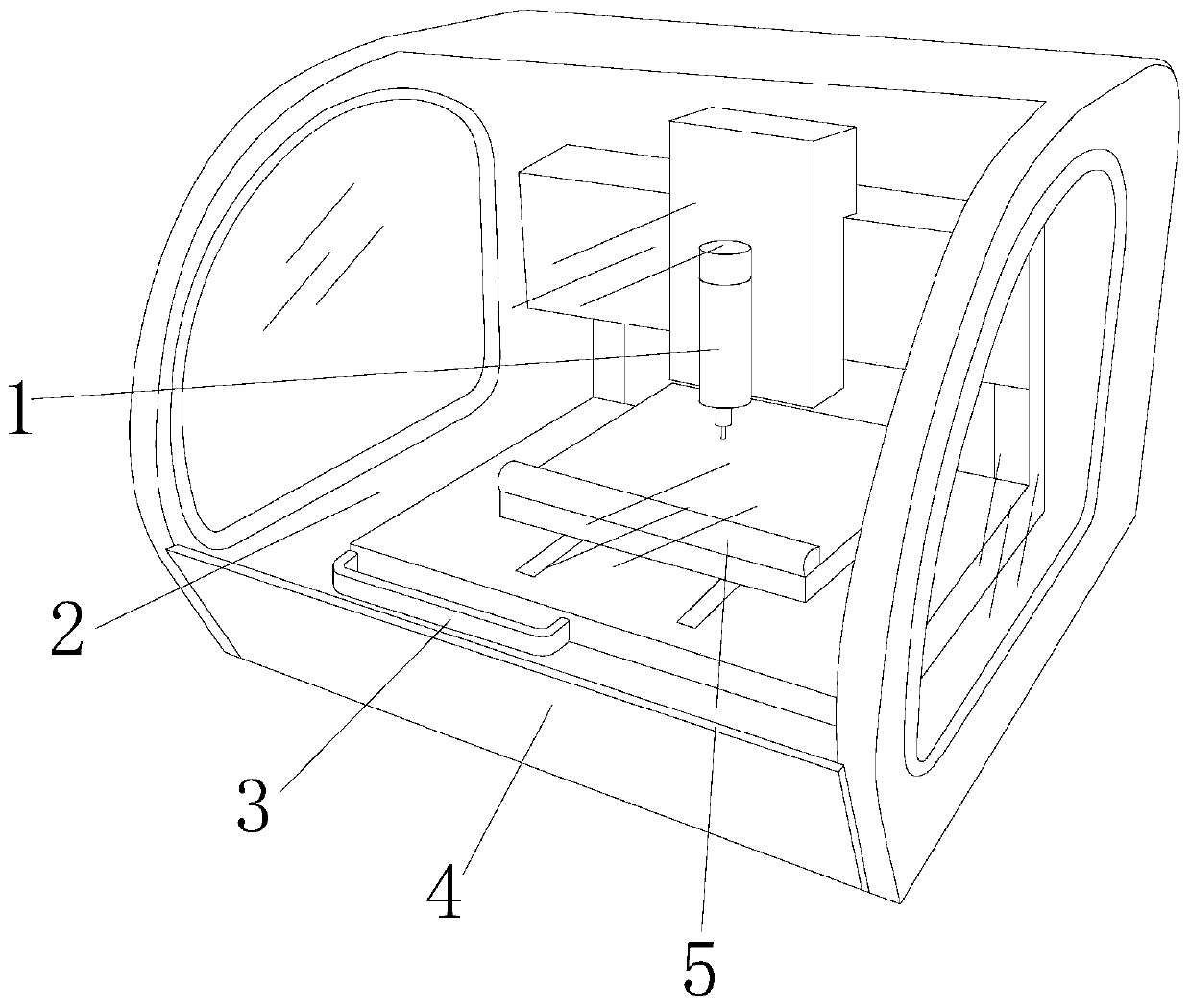

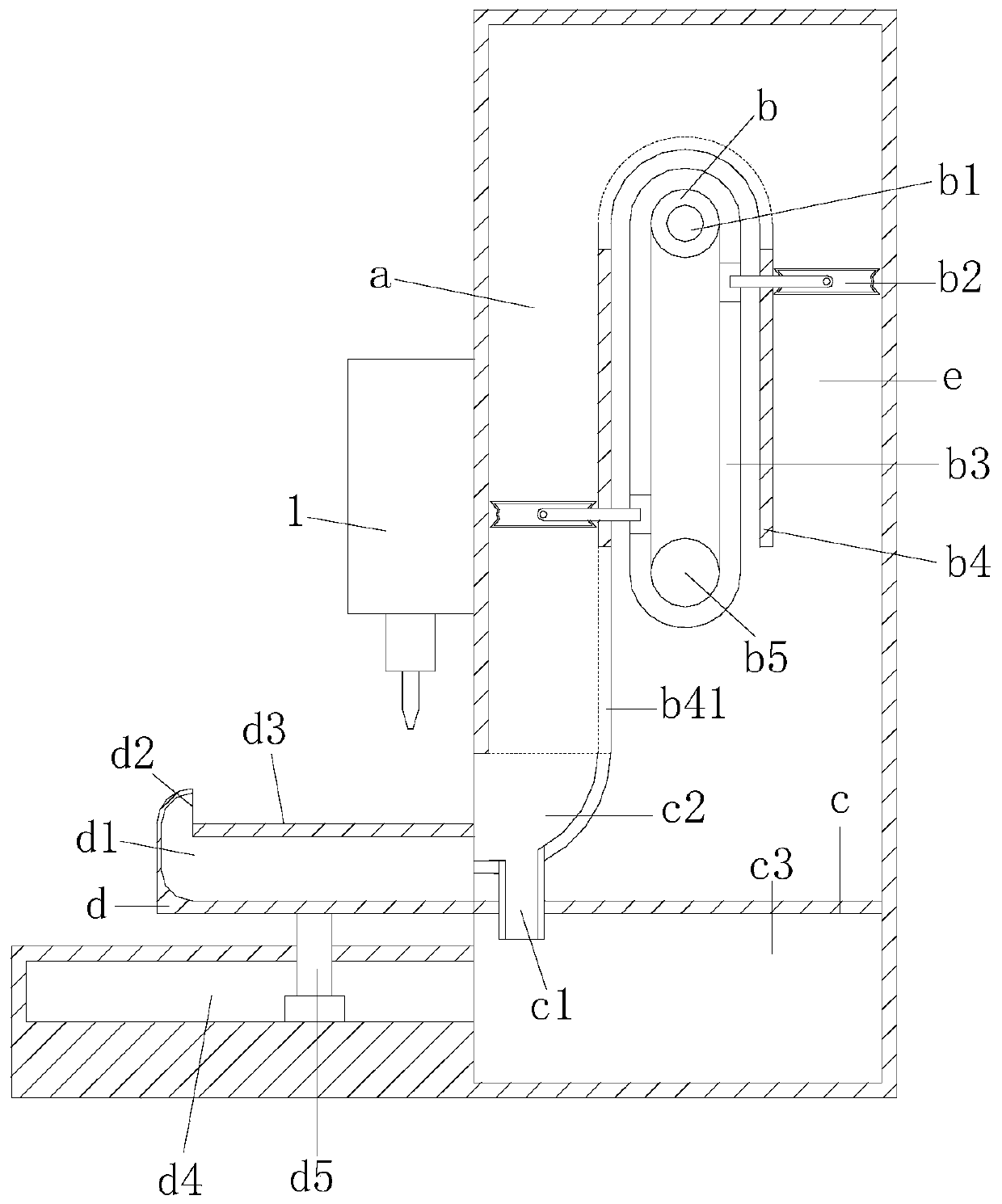

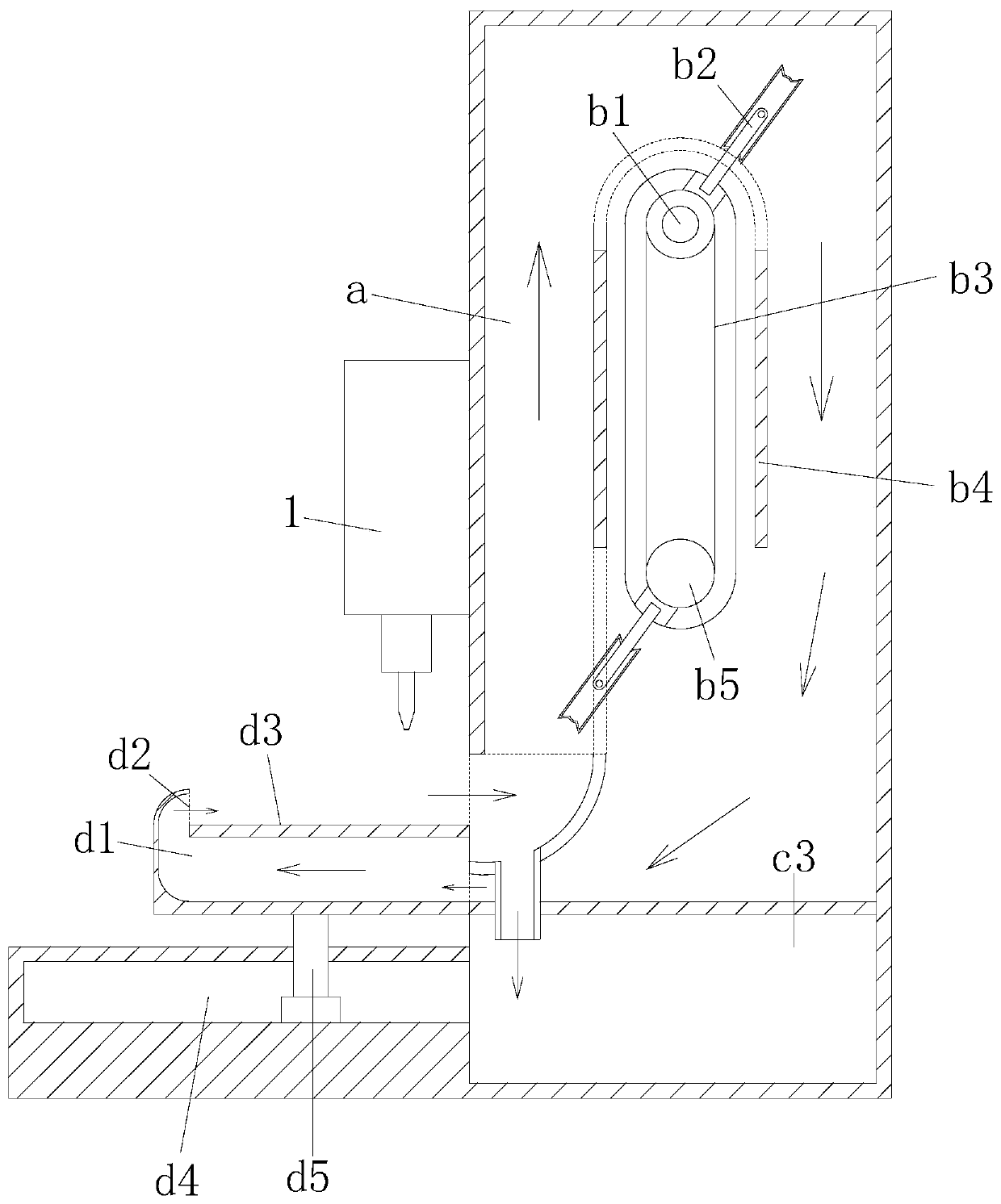

[0025] see Figure 1-Figure 6 , the present invention provides a drilling machine for integrated circuit board production, its structure includes a punching head 1, a working chamber 2, a handle 3, a housing 4, and a workbench 5, and the punching head 1 is installed in the working chamber 2 , the cavity surrounded by the housing 4 is the working chamber 2, the housing 4 is provided with a transparent glass plate, and the glass plate is equipped with a handle 3, the workbench 5 is located in the working chamber 2, The workbench 5 is matched with the punching head 1;

[0026] The workbench 5 is composed of No. 1 channel a, wind power generator b, debris recovery box c, processing table d, and No. 2 channel e. The No. 1 channel a communicates with No. 2 channel e, and the wind force The generating device b is connected to No. 1 channel a and No. 2 channel e, the processing table d is connected to the wind power generating device b, and the debris recovery box c is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com