A charging pile with automatic one-way take-up

A charging pile, one-way technology, applied in the direction of electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems that the charging gun cannot be automatically retracted, the charging line drags the floor, and is damaged, so as to prevent reverse rotation and prevent The effect of mopping the floor and protecting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

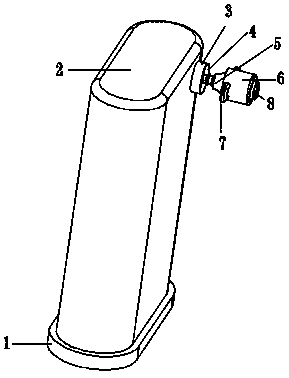

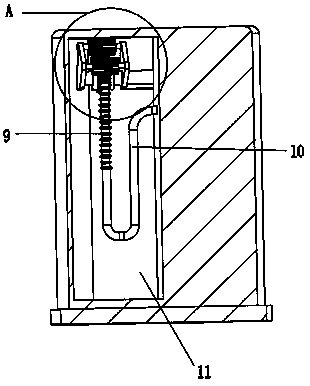

[0025] A specific application of this embodiment is: the present invention is connected to the charging device through the connecting long tube 10. When the user uses the charging gun, the charging gun 6 is pulled out by manually operating the handle 7. After use, the motor is started by controlling 13. The protruding connecting long tube 10 can be recovered through the engagement of the protrusion 9 and the stop tooth 25, and the connecting long tube 10 can be recovered, and the recovery of the connecting long tube 10 can be limited by the action of the two sets of movable tubes 20. To prevent the long connection tube 10 in the cavity 11 from twisting, the charging gun 6 can be accurately stuck on the gun outlet 3 through the cooperation of the arc surface 4 and the arc end surface 5, which facilitates the fixing of the charging gun 6 .

Embodiment 2

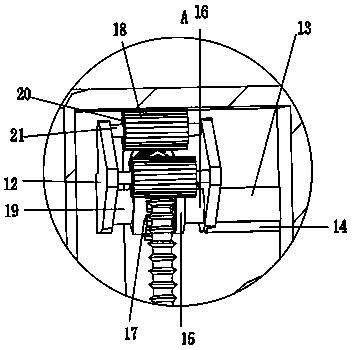

[0026] Embodiment 2: When the motor 13 rotates, the motor 13 drives the main shaft 16 and the outer disk 15 of the main shaft to rotate, and the main shaft 16 drives the cross turntable 22 to rotate, and the rotation of the cross turntable 22 generates centrifugal force so that the cylindrical column 24 is thrown toward The narrow side of the notch groove 26, through the extrusion effect of the cylindrical column 24, makes the cross turntable 22 drive the outer shell 17 to rotate, and through the engagement of the protrusion 9 and the stop tooth 25, the long connecting pipe 10 is recovered. When the long connecting pipe is pulled out manually At 10 o'clock, drive the casing 17 to rotate, extrude the cylinder column 24, so that the cylinder column 24 can overcome the elastic force of the spring 23 and enter the wide side of the notch groove 26, without driving the cross turntable 22 to rotate, and protect the motor 13. This device can realize automatic Take up the line to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com