Crawler-type non-repeated-supporting single-span support carrier

A support truck and crawler-type technology, which is applied in the direction of crawler vehicles, lifting frames, motor vehicles, etc., can solve the problems of wheel-type support trucks driving difficulties, mine material transportation difficulties, and high ground specific pressure, etc., to increase the stand-alone Effects of utilization rate, improvement of vehicle passability, and reduction of purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

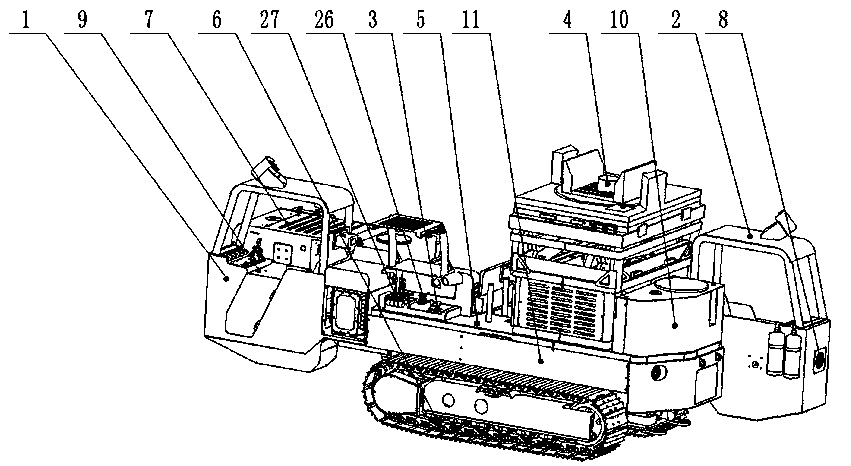

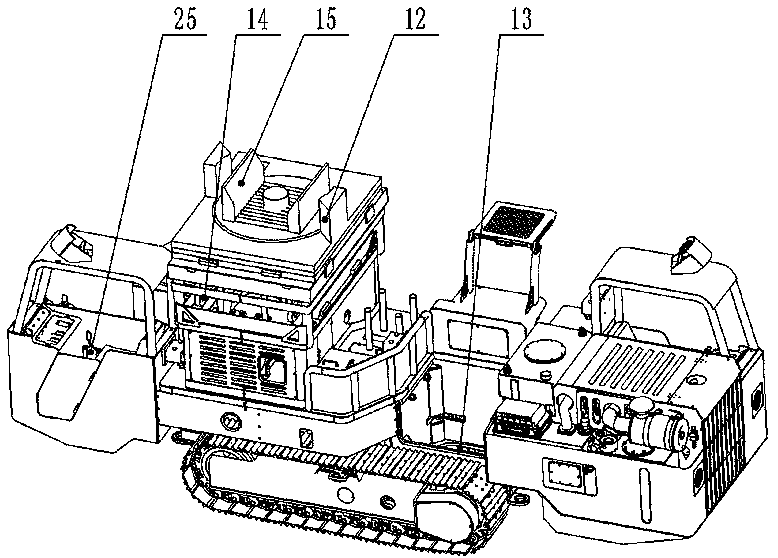

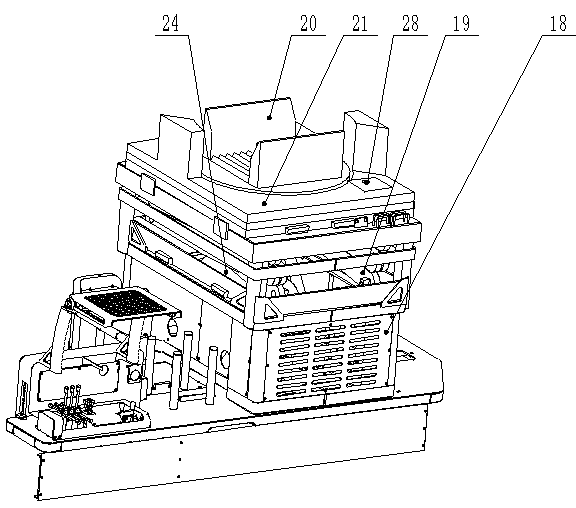

[0017] A crawler-type non-repeatedly supported single-span support truck, including a main driver's cab 1, a co-driver's cab 2, a frame 5, a crawler belt assembly 6, a diesel engine system 7 and an electrical system 8, and the frame 5 is arranged on the crawler belt assembly 6 On the front and back of the frame 5, the main driver's cab 1, the auxiliary driver's cab 2, the fuel tank 11, the diesel engine system 7 and the electrical system 8 are respectively arranged, and the lifting and clamping platform 4 is arranged in the middle of the frame 5, and the lifting and clamping platform 4 includes The supporting frame 18 of the lifting platform, the supporting frame 18 of the lifting platform supports and connects the double-fork lifting platform 19 and the frame 5, the double-fork lifting platform 19 is controlled by the platform hydraulic system 14, and 2 lifting cylinders 24 control the lifting of the platform, and the double-fork lifting platform 19 The middle part is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com