Method for sealing the liquid injection hole of the ionic rare earth in-situ leaching field

An ionic rare earth, in-situ leaching technology, which can be used in earthwork drilling, sealing/sealing, improvement of process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

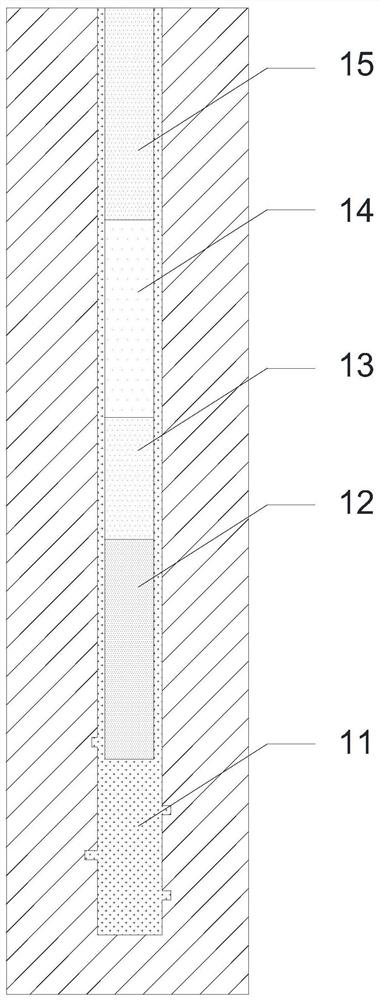

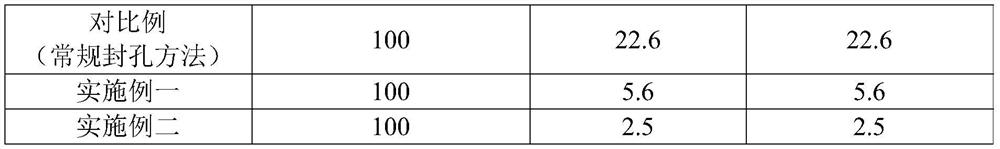

[0059] The method for sealing the liquid injection hole of the ionic rare earth in-situ leaching field provided in this embodiment, the steps are:

[0060] (1) Use clay to prepare mud with a mass concentration of 30%.

[0061] (2) Mud plugging: inject the prepared mud into the liquid injection hole to be closed, observe the drop of the mud level, stop injecting the mud when the rate of the mud level drops to 2mm / h, and pump out most of the mud in the hole, Keep 1 / 4 hole deep mud in the hole.

[0062] (3) Original soil backfill: backfill the rock and soil left over from the construction of the injection hole into the injection hole, tamp once every 10cm backfill, and backfill until 150cm away from the orifice;

[0063] (4) Lime backfill: backfill lime on the original soil backfill section with a thickness of 30cm;

[0064] (5) Clay backfill: backfill clay on the lime backfill section with a thickness of 50cm;

[0065] (6) Topsoil backfill: backfill the topsoil produced by th...

Embodiment 2

[0067] The liquid injection hole sealing method of the ionic rare earth in-situ leaching field provided in this embodiment is basically the same as that in Embodiment 1. The only difference is that the mud mass concentration is 40% in step (1); 1 / 3 deep mud is retained in the holes in step (2), and a lime filler section with a thickness of 20 cm is formed in step (4).

Embodiment 3

[0069] The liquid injection hole sealing method of the ionic rare earth in-situ leaching field provided in this embodiment is basically the same as that in Embodiment 1. The only difference is that in step (1), the mud material is bentonite, in step (2), 1 / 3 of the deep mud is retained in the holes, and in step (5), a clay section with a thickness of 50 cm is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com