Adjustable automatic locking mechanism

An adjustable and automatic technology, applied in the direction of building structure, construction, etc., can solve the problem of inability to fasten connection between two floor slabs or wall panels, and achieve the effect of reducing the time-consuming work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

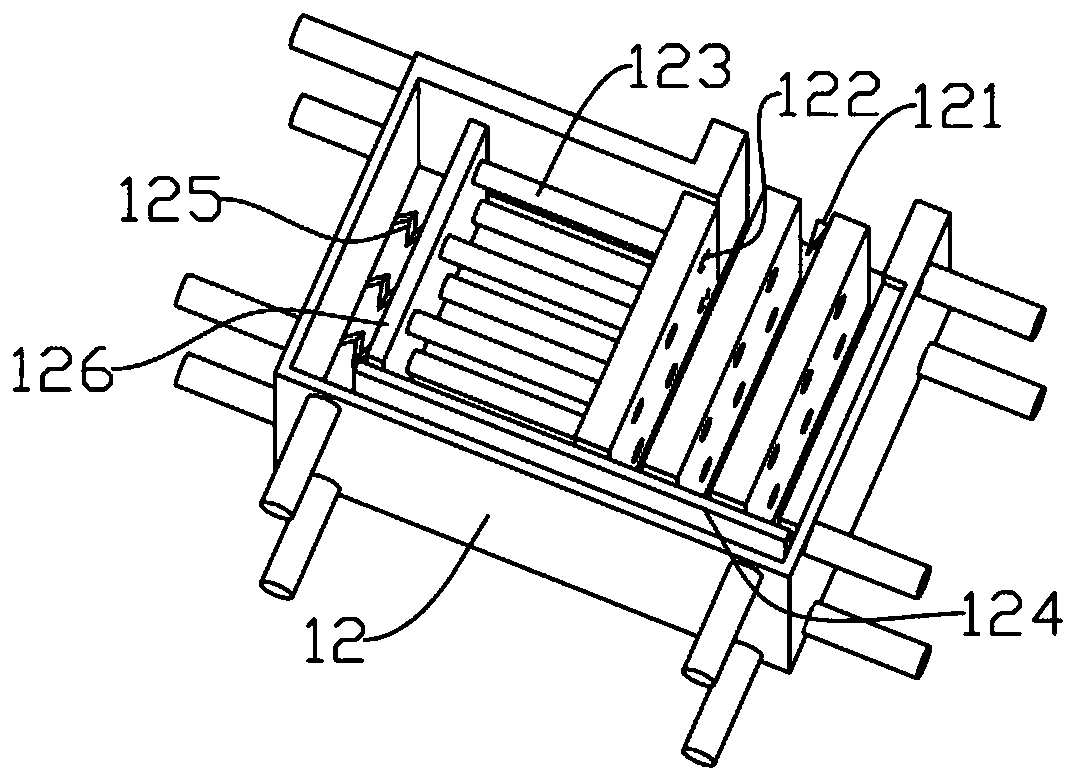

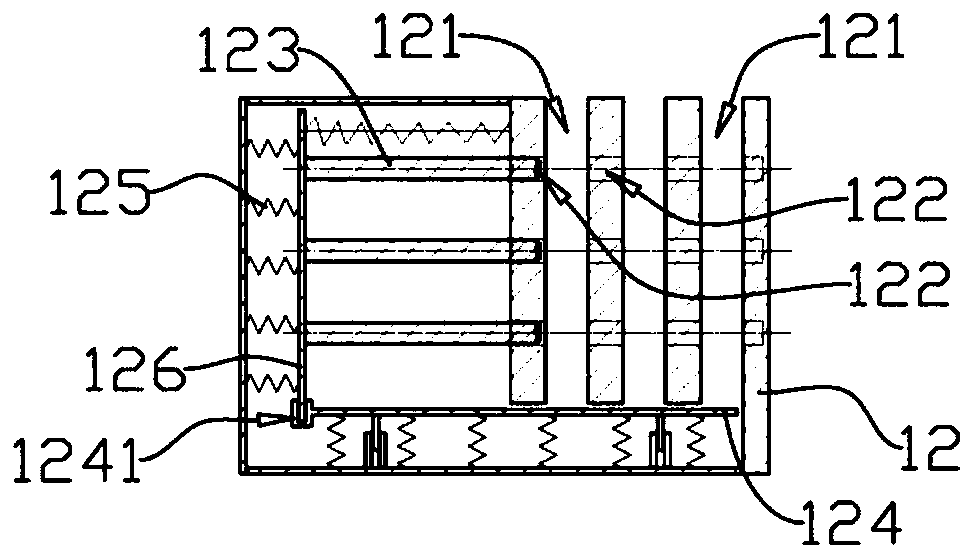

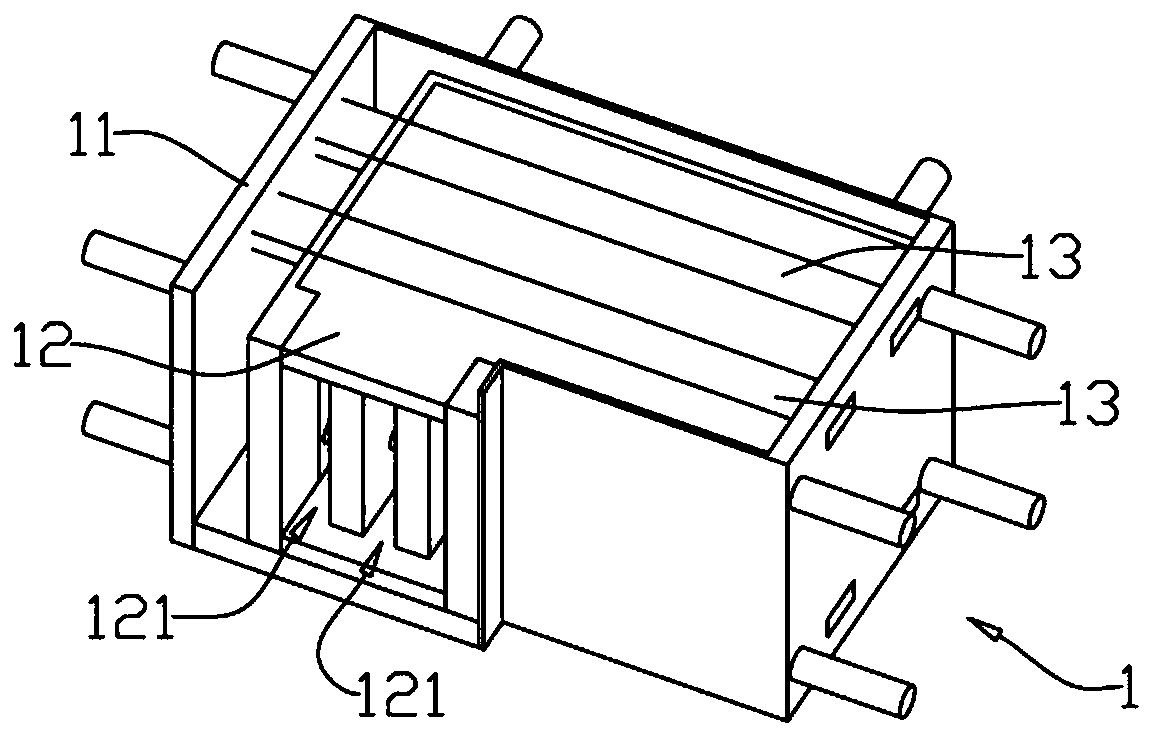

[0026] combine Figure 1 to Figure 4 As shown, the adjustable automatic locking mechanism of the present invention is schematically shown, including a locking part 1 and a plugging part 2 .

[0027] Such as Figure 1 to Figure 3 , the locking part 1 includes a hollow first housing 11 and a lock body 12 that is movably arranged on the first housing 11, which enables the lock body 12 to move in the first housing 11, and the plug-in part 2 includes a hollow The second housing 21 and the plug connector 22 movably arranged on the second housing 21 , the plug connector 22 is in the shape of a plate, and the plug connector 22 can be extended or retracted from the second housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com