Automatic control overhauling method of coal mining machine, electronic equipment oversized mining height coal mining machine

An electronic device and a technology for a shearer, applied in the field of shearers, can solve the problems of a large amount of refueling and the inability to guarantee the horizontal state of a rocker arm of the shearer, and achieve the effect of improving the start-up rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0051] Such as Figure 5 Shown is a working flow chart of an automatic control and repair method for a coal shearer in the present invention, including:

[0052] Step S501, in response to the event that the shearer enters the maintenance mode, obtain information about a sensor installed on the rocker arm of the shearer;

[0053] Step S502: Control the lifting and lowering of the rocker arm of the shearer according to the information of the sensor until the rocker arm of the shearer is in a horizontal state.

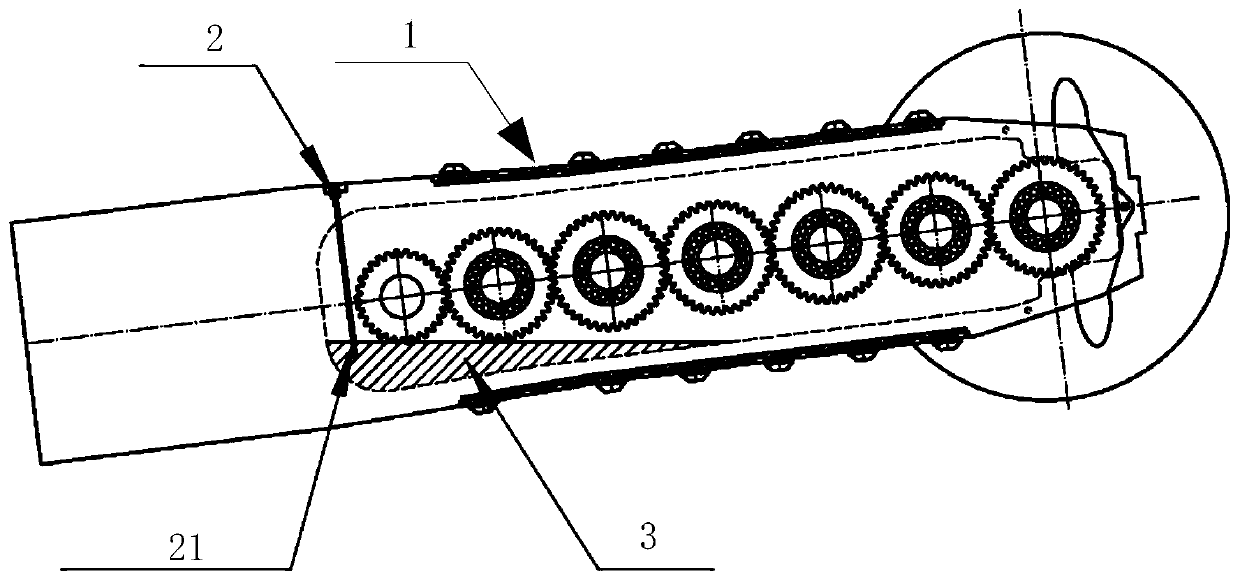

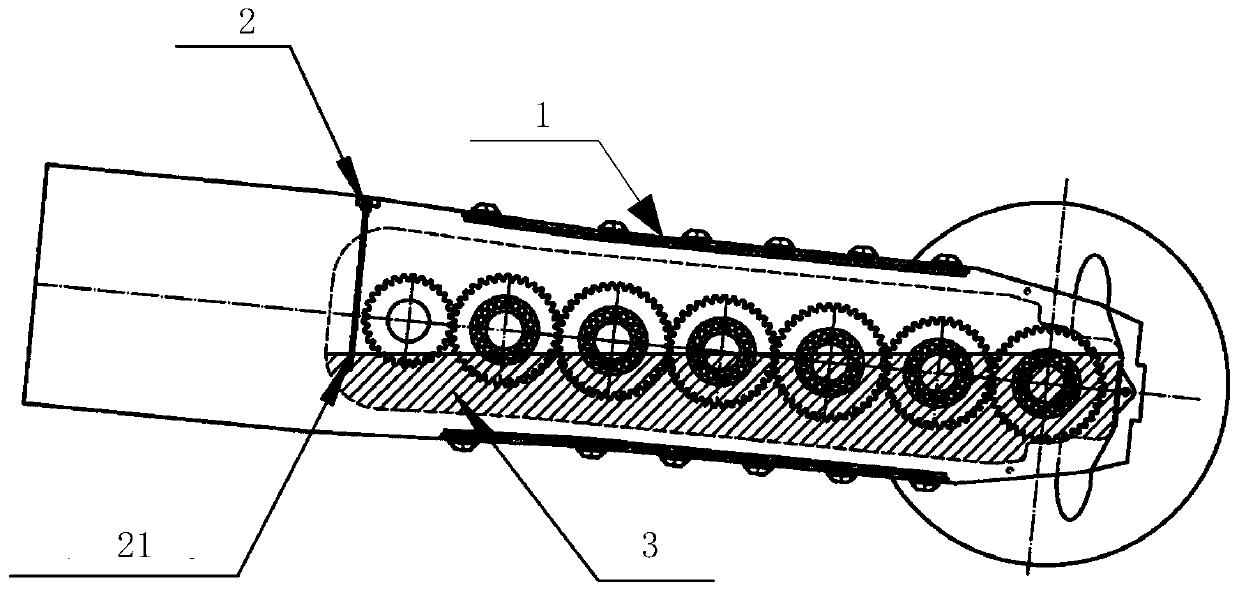

[0054] Specifically, when the shearer enters the maintenance mode, step S501 is triggered. As the shearer is under maintenance, the rocker arm 1 needs to be in Figure 4 As shown in the horizontal state, otherwise it will appear as Figure 2 to Figure 3 The situation shown makes it impossible to refuel accurately. Therefore, step S501 obtains the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com