Solid rocket engine case belt drive continuous filling pouring device and process

An engine casing and solid rocket technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increasing demand for small solid rocket engines, many types of auxiliary supporting systems, and poor slurry flow control accuracy. To achieve the effect of simplifying the complex work mode, reducing the amount of residual slurry, and reducing the cost of civil engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

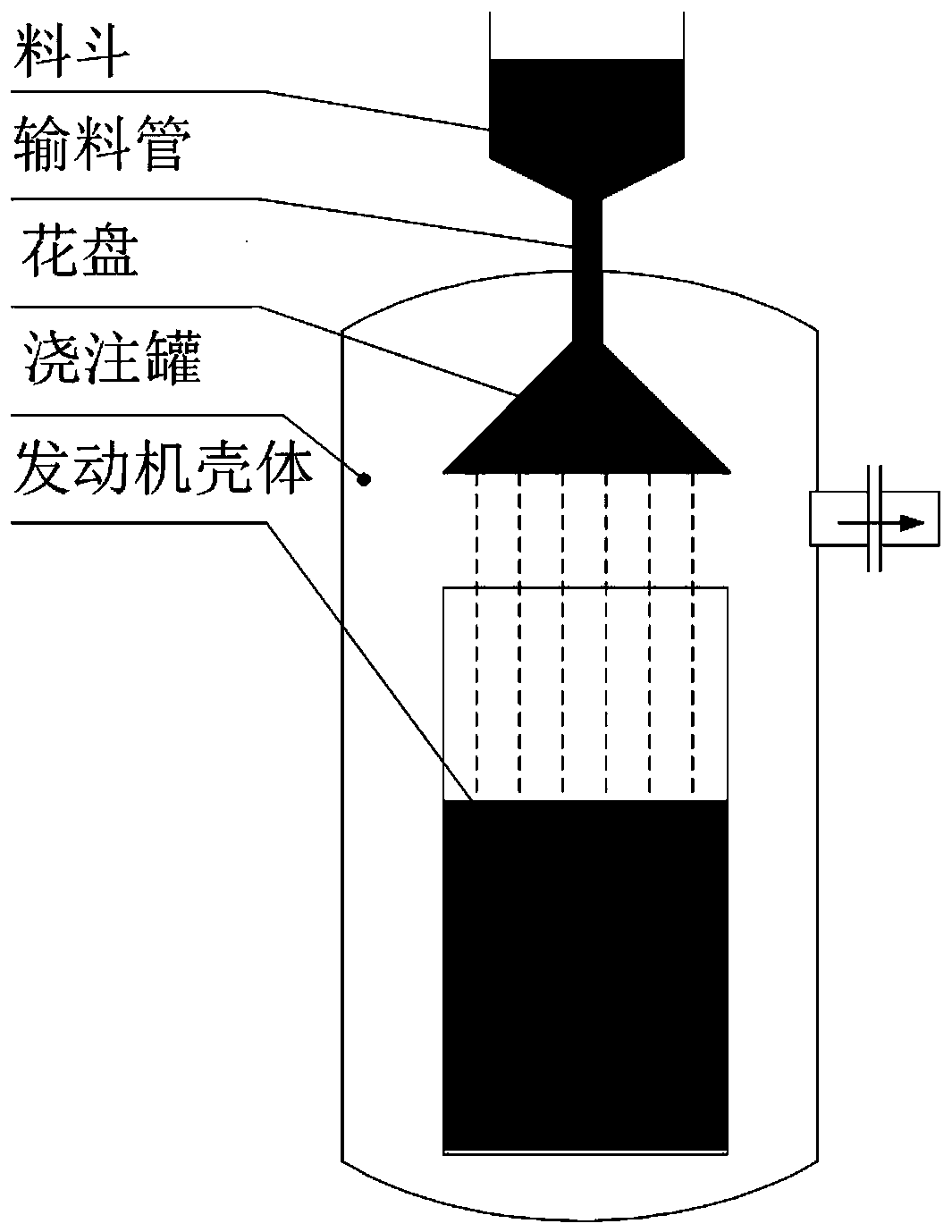

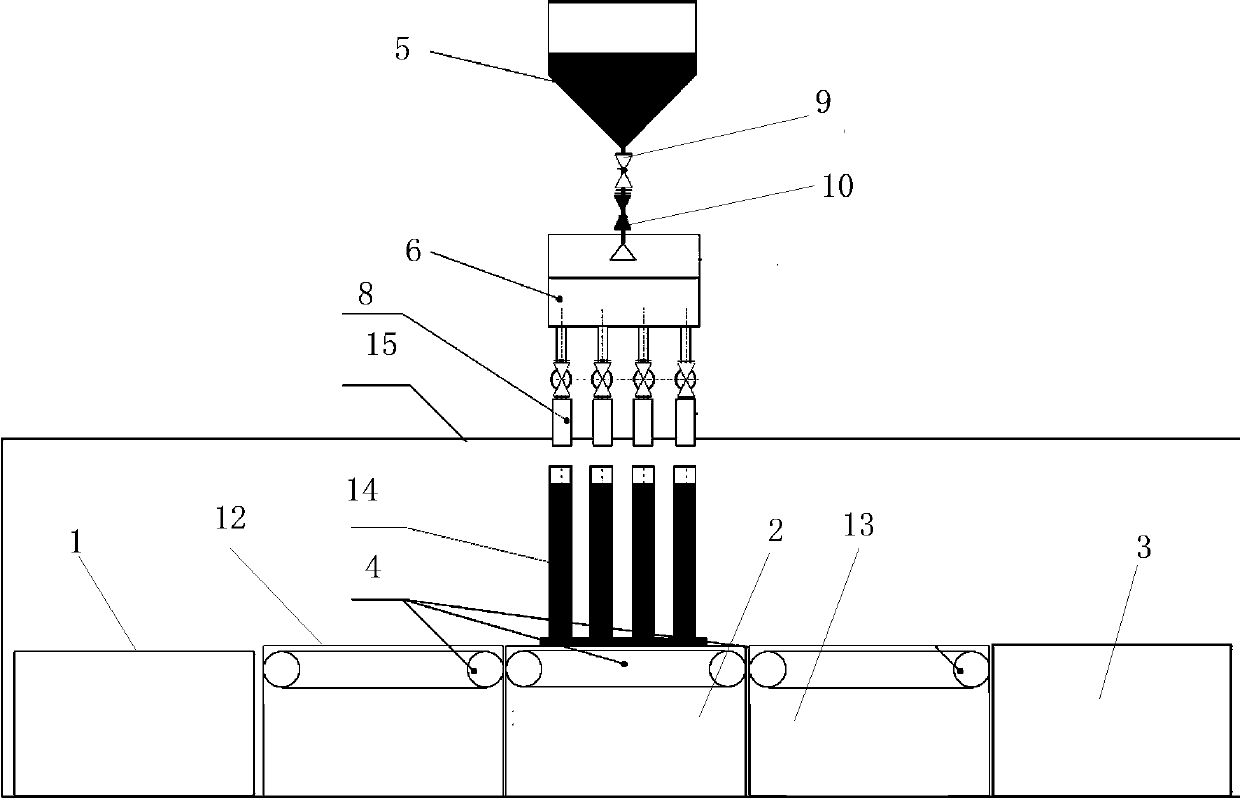

[0029] like Figure 2-4 As shown, a solid rocket motor casing belt drive continuous filling pouring equipment, including pouring preparation area 1, pouring area 2 and discharge area 3 arranged in sequence, between pouring preparation area 1, pouring area 2 and discharge area 3 Conveyor belts 4 are arranged in sequence; the primary hopper 5 is arranged above the conveyor belt in the pouring area, and the secondary hopper 6 is connected below the primary hopper. A reciprocating pump 7 is arranged on the pipeline between the head 8, the discharge port and the filling head. The filling head 8 cooperates with the engine casing 14 to realize pouring. The secondary hopper and the canning head are connected with a vacuum pipeline. Through the quantitative and metered feeding technology of reciprocating pumps, combined with the special requirements of dangerous cremation workplaces and the pouring process characteristics of solid rocket motor casings, an assembly line production opera...

Embodiment 2

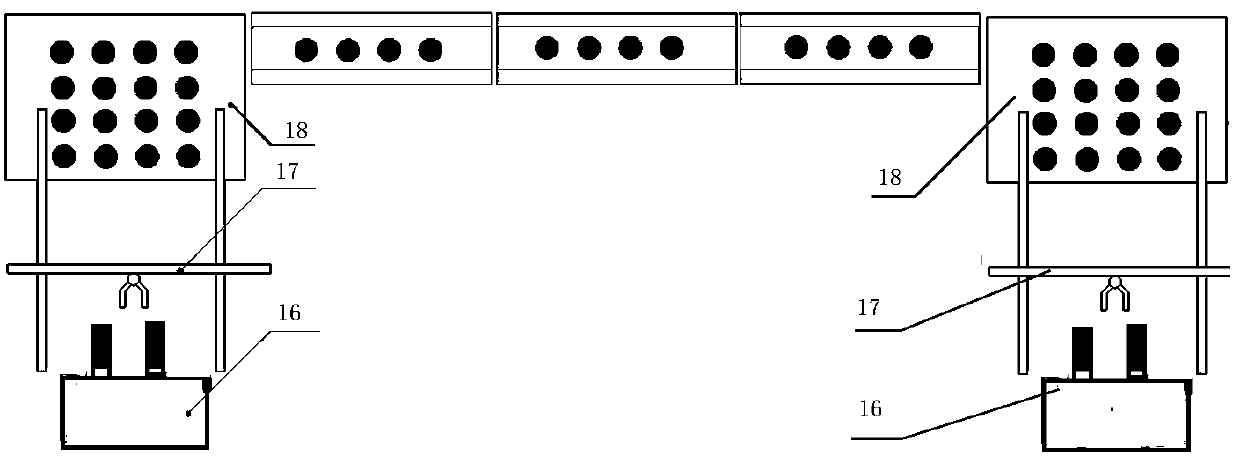

[0042]Carry out canned pouring for the engine casing with a specification of Ø200×XXXmm. During the specific operation, the process of transporting the engine casing (hereinafter referred to as the casing) to the pouring area, the working process is that the casing is packed with a set of brackets for 16 sets The AGV intelligent transfer vehicle (hereinafter referred to as AGV) is transferred from the warehouse to the truss manipulator position in the preparation area, and the truss manipulator grabs the upper shell of the AGV one by one and transfers it to the feeder. The feeder presses 4 shells one by one. The group pushes to the conveyor belt, and the conveyor belt transports the received shells to the waiting area, and then transports them to the pouring area when pouring is required. In the preparation stage, it is also necessary to prepare the mixed slurry. Specifically, the mixed slurry is transferred to the primary pouring hopper, and the primary hopper is hoisted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com