Safe hydraulic valve for hydraulic electric control system

An electrical control system and hydraulic valve technology, applied in the field of safety hydraulic valves, can solve the problems of poor reliability of electromagnetic safety valves, long maintenance time of electromagnetic valves, hidden dangers in safety, etc., and achieve stable work, good airtightness, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

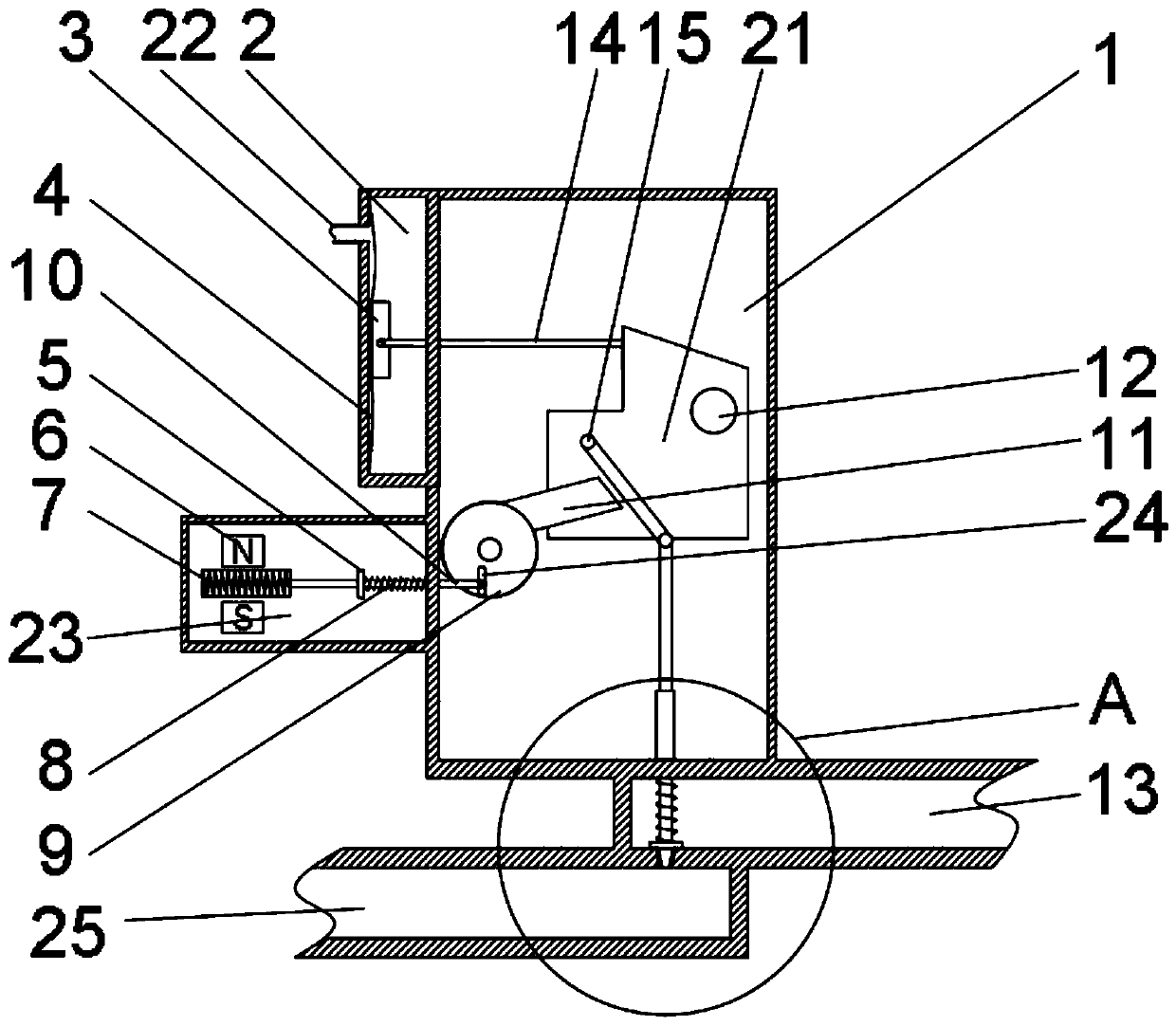

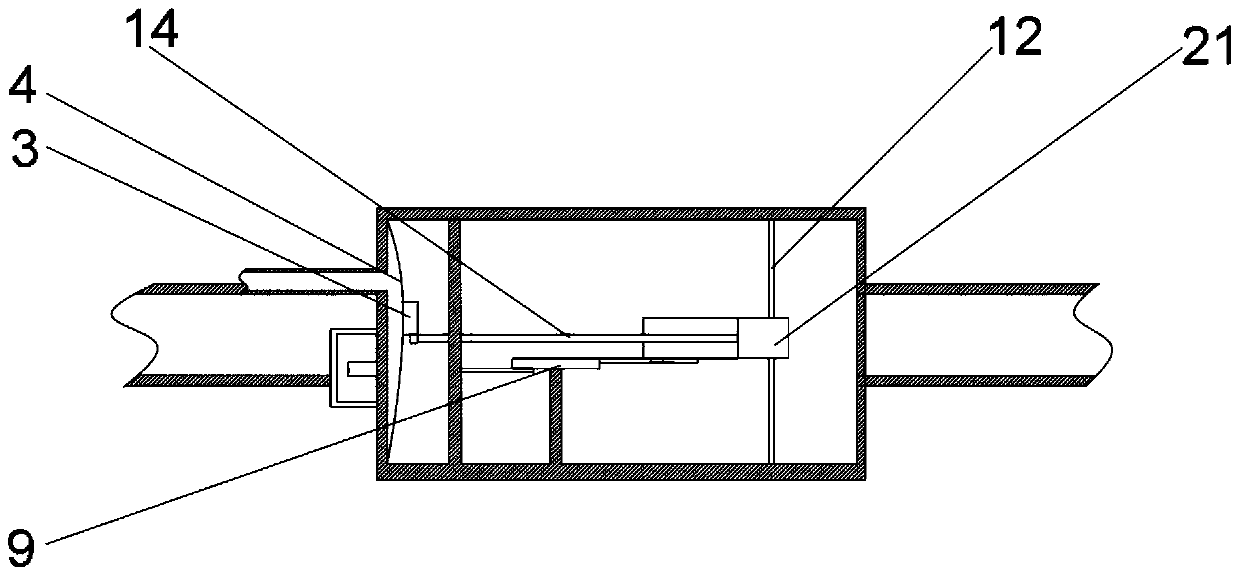

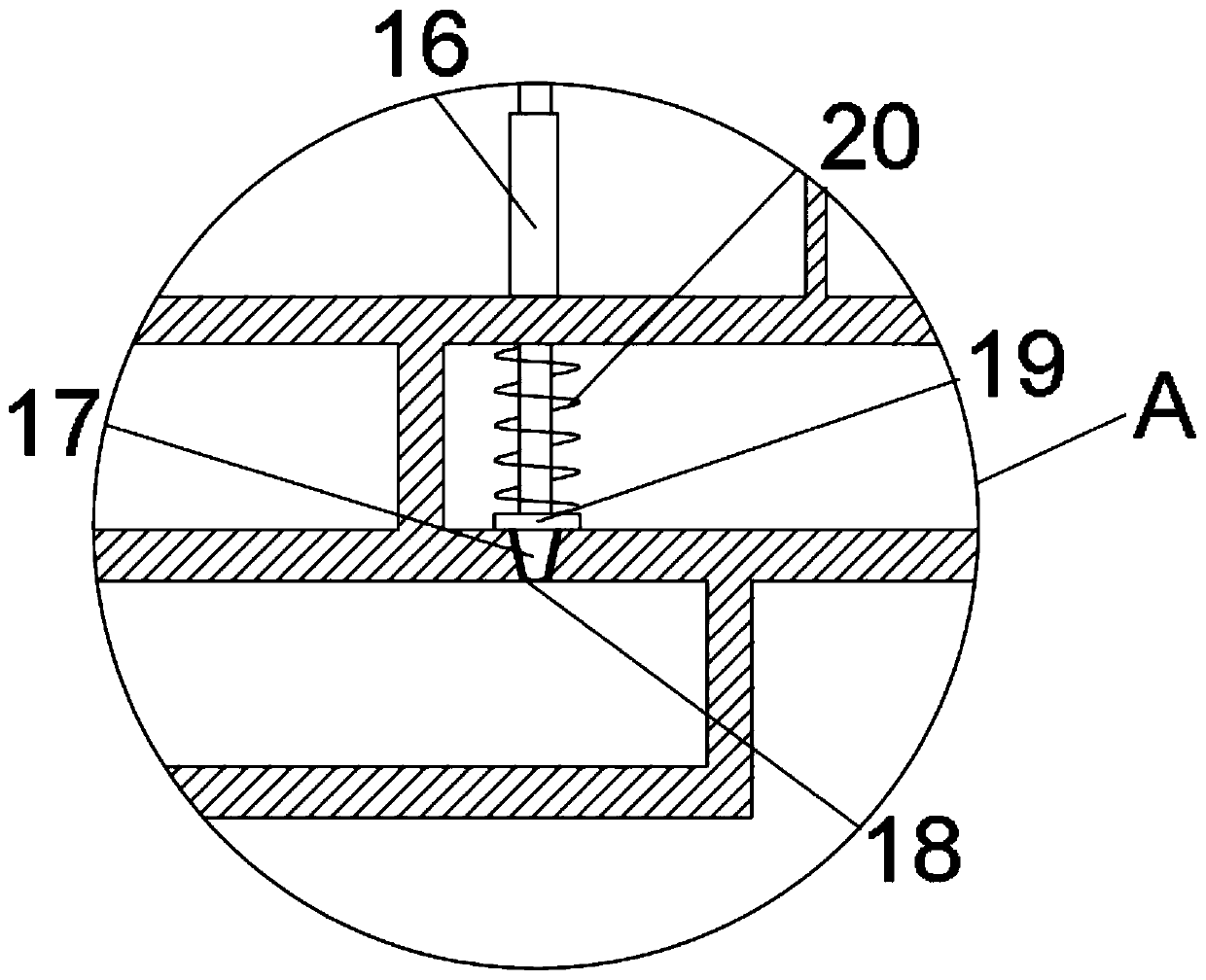

[0029] as attached figure 1 The shown safety hydraulic valve for a hydraulic electrical control system of the present invention includes a solenoid valve chamber 1, a side of the outer surface of the solenoid valve chamber 1 is fixedly connected with a pressure measuring chamber 2, and a piston 3 is installed inside the pressure measuring chamber 2. One side of the outer surface of 3 is fixedly connected with a membrane 4, and the end of the piston 3 away from the membrane 4 is fixedly connected with a piston rod 14, and the membrane 4 is fixedly connected with the bottom end of the pressure measuring chamber 2, and the piston rod 14 penetrates the inner wall of the pressure measuring chamber 1, The film 4 can make the airtightness of the pressure vessel better, and the film 4 is soft in texture and has high pressure response sensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com