A reformer furnace door insulation device and its preparation method

A thermal insulation device and conversion furnace technology, applied to chemical instruments and methods, furnaces, manufacturing tools, etc., can solve problems such as potential safety hazards, burn-through, collapse of ceramic fiber modules, etc., achieve good heat insulation, increase service life, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

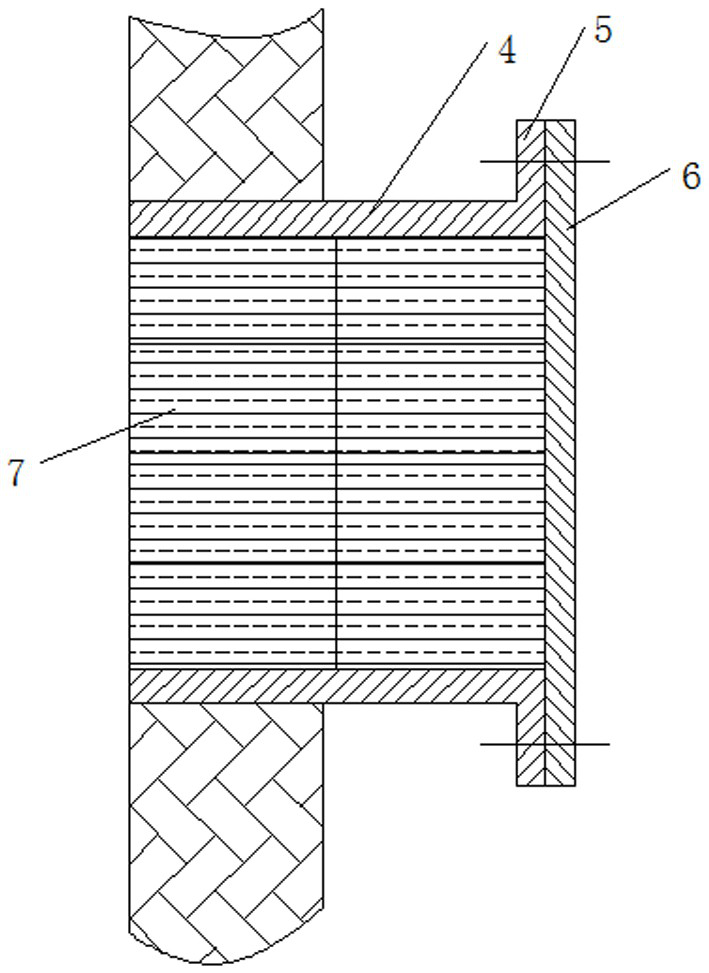

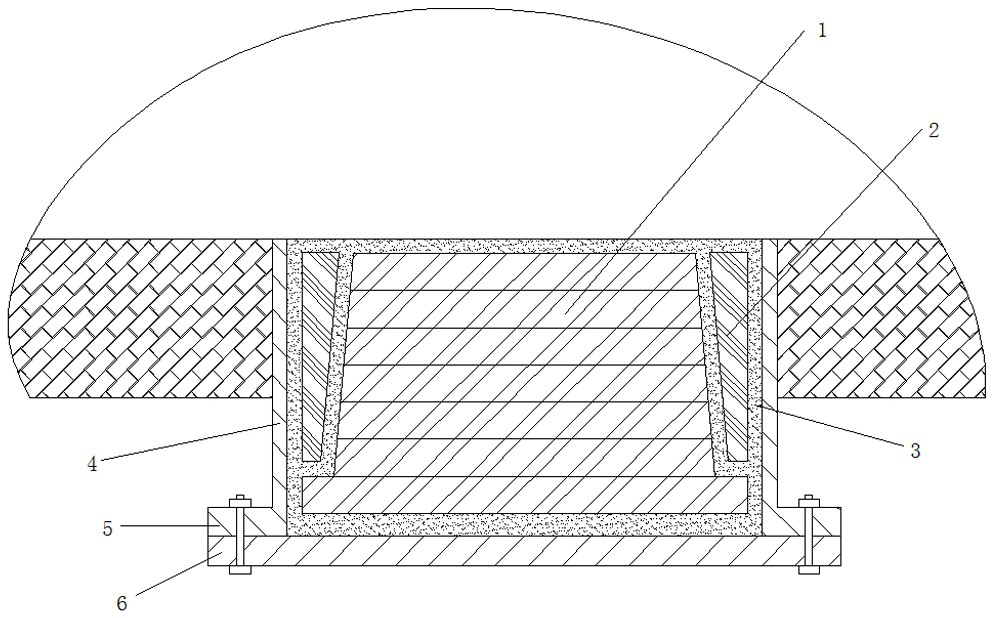

[0034] In the prior art, such as figure 1 As shown, in order to achieve the heat preservation of the reformer furnace door, it is usually necessary for the operator to stack and insert the ceramic fiber modules 7 in the furnace door channel 4, and then use a poke stick to compact the ceramic fiber module 7 and the inner wall of the furnace door channel 4. Finally, connect the flange steel plate 6 with the furnace door flange 5, and the flange steel plate 6 presses the ceramic fiber module 7 to achieve the purpose of heat insulation. In this heat preservation structure, the ceramic fiber module 7 will be baked by the high-temperature airflow inside the reformer. After a period of use, it will be burned from the part close to the furnace door channel 4 to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com