Nondestructive prediction combination method for evaluating rock uniaxial compressive strength under freeze-thaw cycle

A technology of uniaxial compressive strength and freeze-thaw cycles, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve the problem of inability to accurately and nondestructively determine the strength and elastic modulus of freeze-thaw rock problem, to achieve the effect of predicting the uniaxial compressive strength of rock accurately, improving accuracy, and reducing deficiencies and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following will further describe in detail the embodiments of the present invention in conjunction with the accompanying drawings.

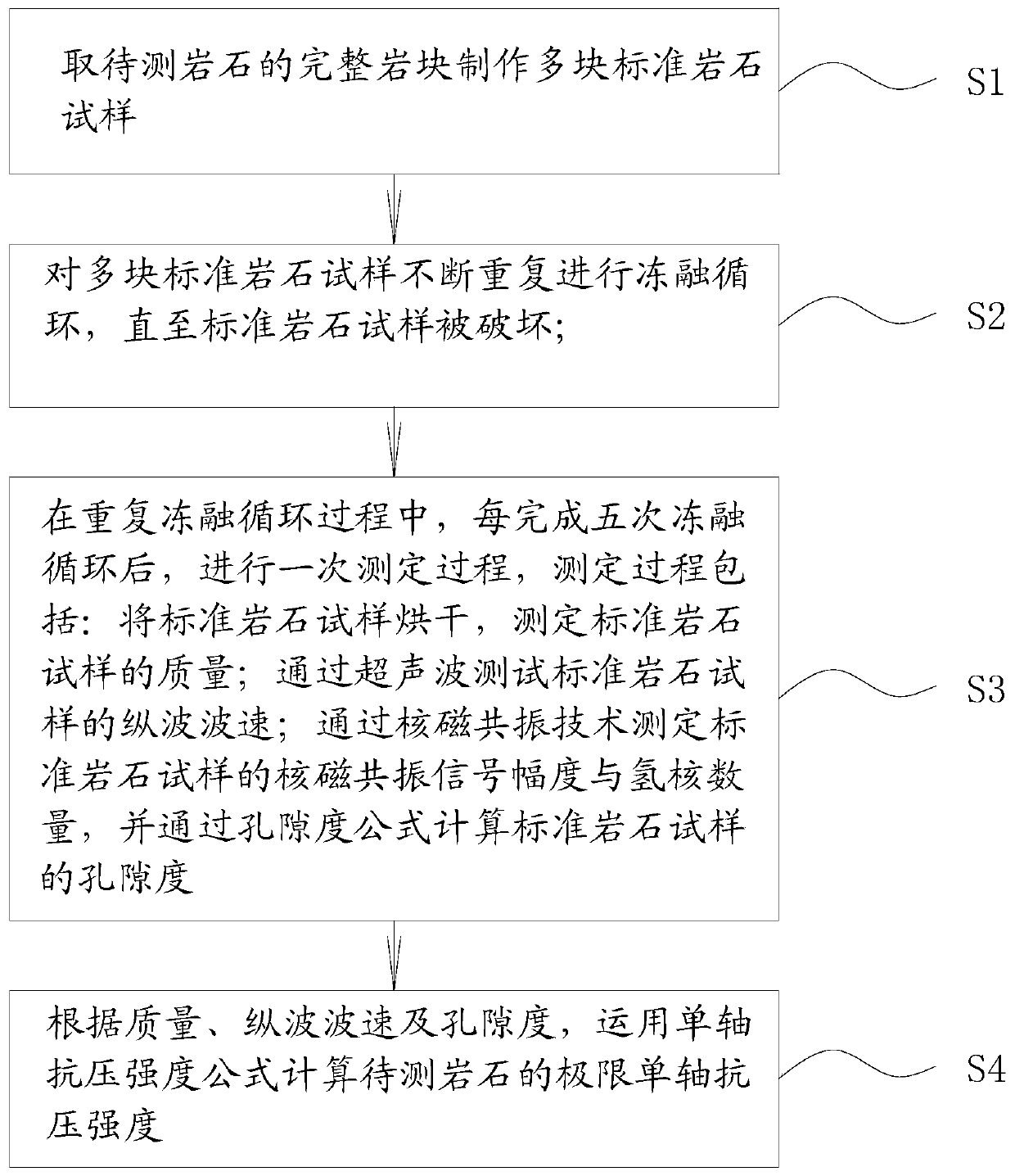

[0046] The present invention provides a non-destructive prediction combined method for evaluating rock uniaxial compressive strength under freeze-thaw cycles, see attached figure 1 , the specific implementation process is as follows:

[0047] First, three standard rock samples (numbered 0, 0-1, 0-2, 5, 5-1, 5-2, 10, 10-1 , 10-2, 15, 15-1, 15-2, 20, 20-1, 20-2, , 25, 25-1, 25-2, 30, 30-1, 30-2, 35, 35- 1, 35-2, 40, 40-1, 40-2, 45, 45-1, 45-2, 50, 50-1, 50-2).

[0048]The three rock samples (0, 0-1, 0-2) are the comparison rock samples, and the uniaxial compression test is carried out to obtain the comparison limit uniaxial compressive strength of the comparison rock samples. The initial masses of the three rock samples were measured and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com