Bidirectional mechanical tuning terahertz wave modulator and preparation method and application thereof

A mechanical tuning and modulator technology, applied in the field of terahertz wave modulators, can solve the problems of complex processing, limited modulation depth and low stretching ability of THz control devices, and achieve low cost, simple preparation and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

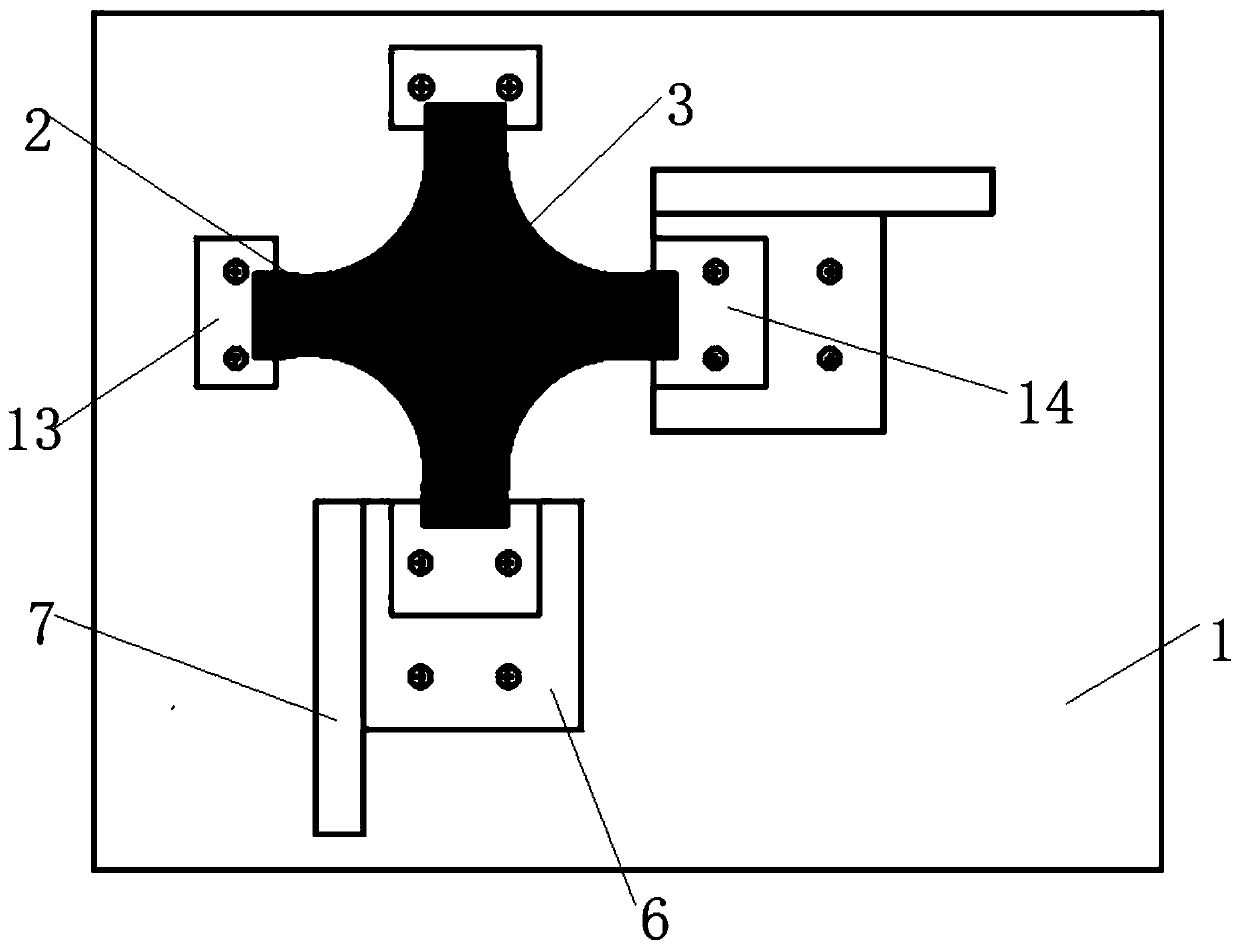

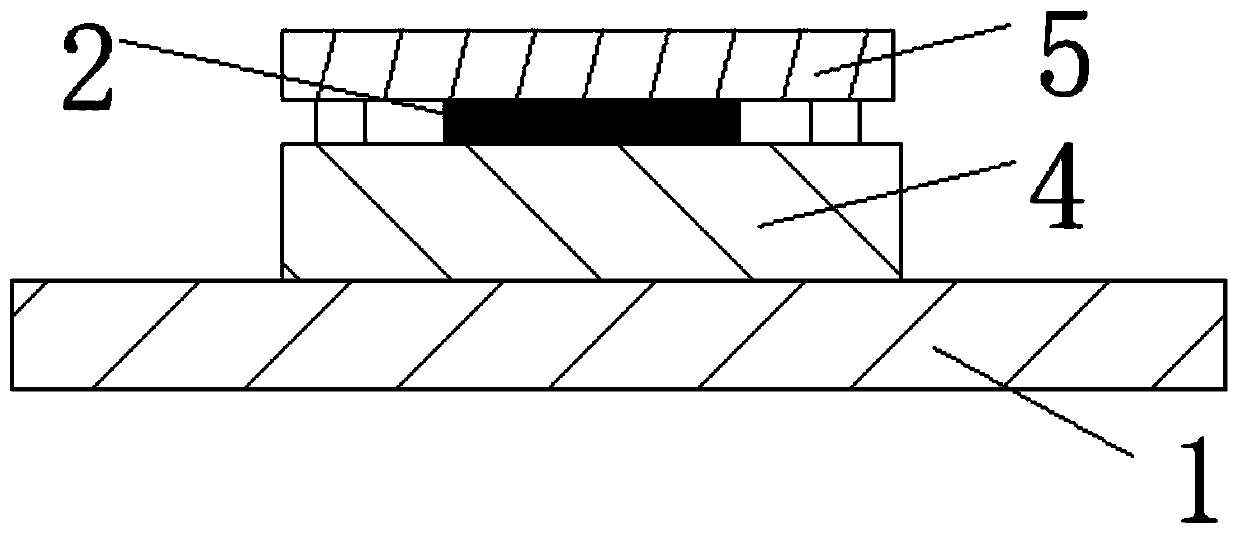

[0040] Such as figure 1As shown, a two-way mechanically tuned terahertz wave modulator includes a fixed control frame. The fixed control frame includes a bottom plate 1. The bottom plate 1 is made of plexiglass. The array element 2, the base plate 1 corresponding to the array element 2 is provided with an opening 3 for the passage of terahertz waves, the right end and the lower end of the array element 2 are connected with a micro-displacement mechanism, and the micro-displacement mechanism is arranged on the base plate 1, and the array element The left end and the upper end of 2 are all arranged on the bottom plate 1 through the first fixing seat 13, as figure 2 As shown, the first fixing seat 13 includes a first fixing plate 4 placed on the base plate 1, a second fixing plate 5 is provided on the side of the first fixing plate 4 away from the base plate 1, and the corresponding end of the array element 2 is placed on the second fixing plate 4. Between the first fixed plate...

Embodiment 2

[0044] This embodiment is basically the same as Implementation 1, the difference is that: Figure 4 and 5 As shown, the array element 2 is a PDMS (polydimethylsiloxane) packaged Ni nanowire array, the Ni nanowire array is in a cross-shaped structure, and the adjacent ends are connected in an arc shape, and the Ni nanowire array includes The Ni nanowire layer 10 arranged in order, one side of the Ni nanowire layer 10 is provided with a PDMS substrate layer 11, and the other side is provided with a PDMS encapsulation layer 12. The orderly arranged Ni nanowire layer 10 means that each Ni nanowire is arranged in parallel.

[0045] The substrate layer or encapsulation layer on both sides of the Ni nanowire layer 10 can also be other flexible materials such as polyimide, p-xylene and the like.

[0046] The Ni nanowire layer 10 can also be any other materials that respond to terahertz, such as nanoparticles, resonant ring arrays, and the like.

Embodiment 3

[0048] The preparation method of a two-way mechanically tuned terahertz wave modulator comprises the following steps:

[0049] (1) prepare Ni nanowire array;

[0050] (2) The Ni nanowire array corresponds to the opening 3 of the bottom plate 1, and the left end and the upper end of the Ni nanowire array are respectively placed between the corresponding first fixing plate 4 and the second fixing plate 5, and then the first fixing plate is fixed by screws. The fixed plate 4 and the second fixed plate 5 are fixed on the bottom plate 1;

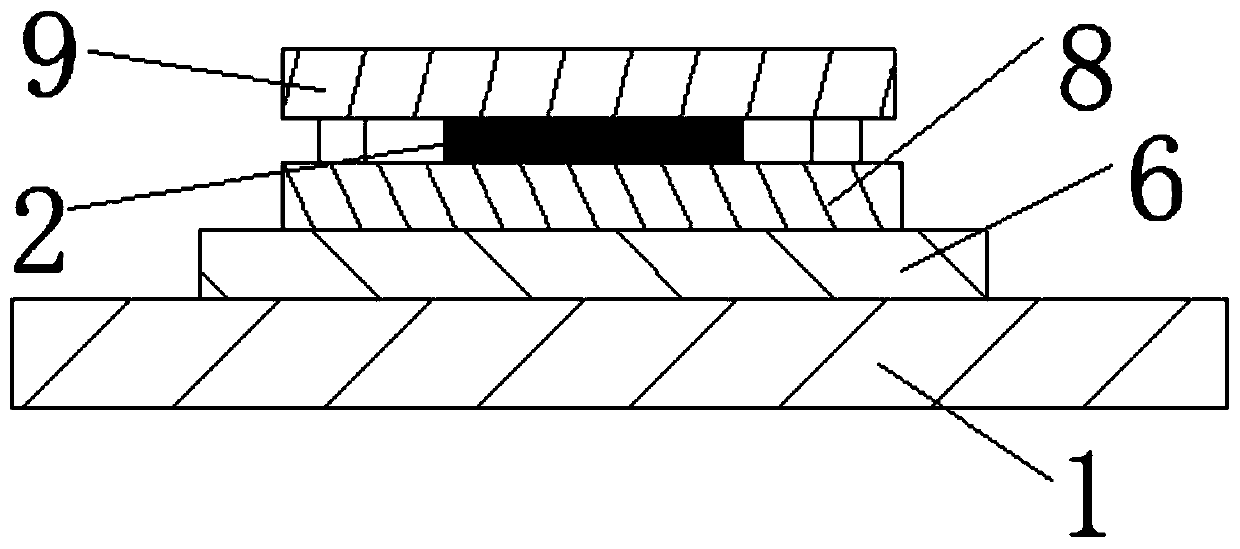

[0051] (3) The right end and the lower end of the Ni nanowire array are respectively fixed between the corresponding third fixed plate 8 and the fourth fixed plate 9, and then the third fixed plate 8 and the fourth fixed plate 9 are fixed on the micro displacement by screws. On the plate platform 6, rotate the micrometer 7 at the right end and / or the lower end to adjust the position of the micro-displacement plate platform 6 on the base plate 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com