Compact drive system and drive method for open-winding permanent magnet synchronous motor

A permanent magnet synchronous motor and drive system technology, applied in the control system, control generator, vector control system, etc., can solve the problems of high complexity of the control system, increase the cost of the drive system, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

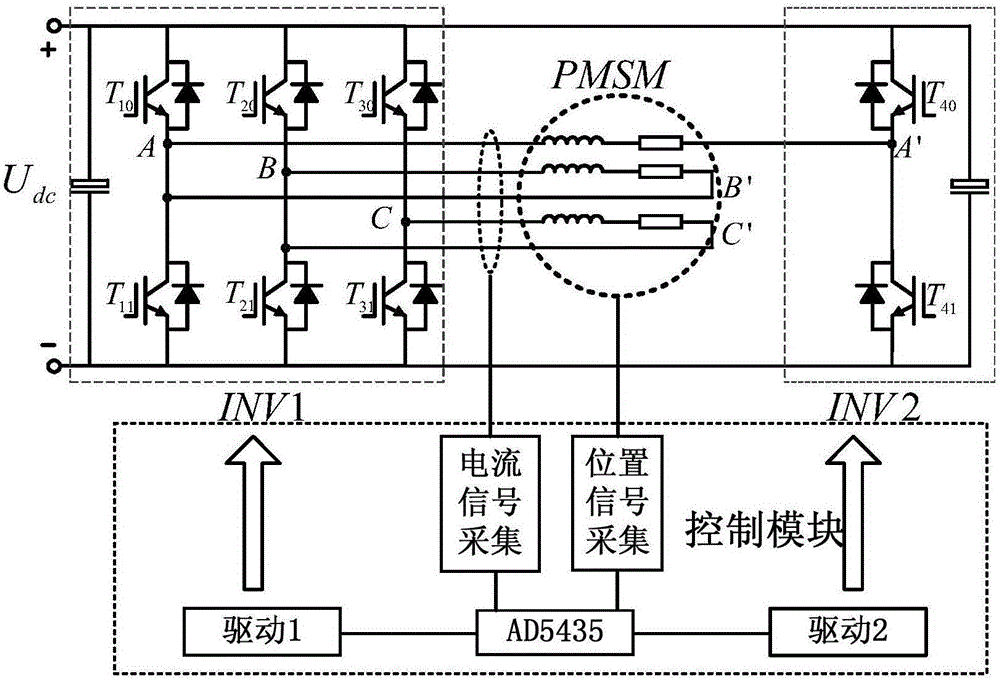

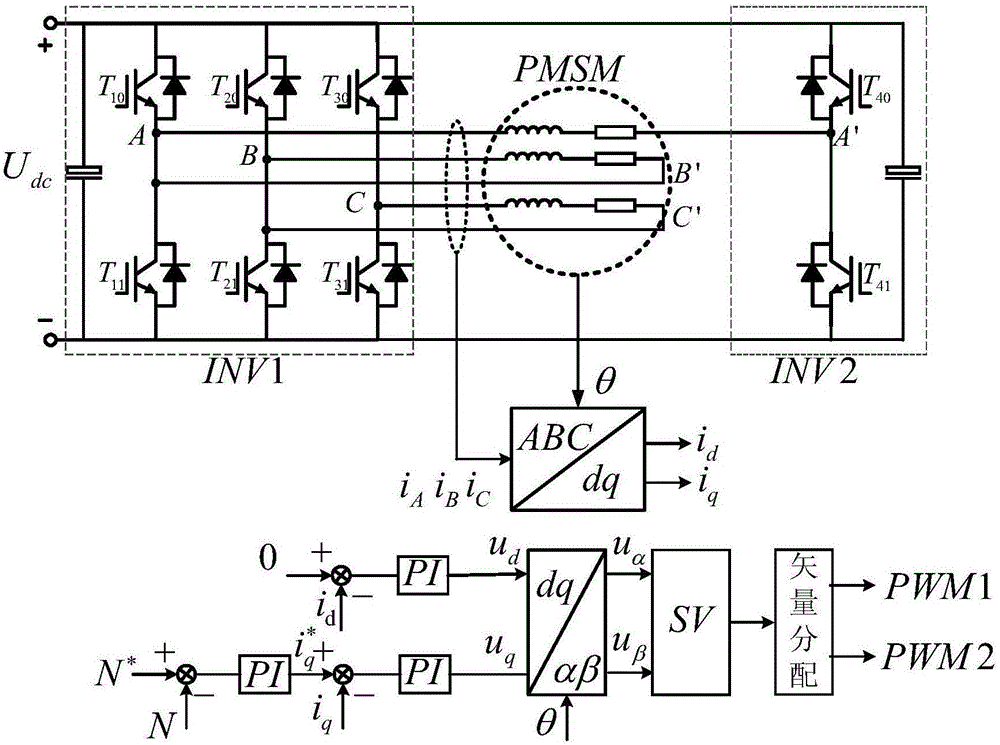

[0038] like figure 1 As shown, the present invention provides a compact drive system for an open-winding permanent magnet synchronous motor, including an open-winding permanent magnet synchronous motor, a four-leg compact converter, a control module and a DC power supply, wherein the control module includes a controller and a The current signal acquisition module, the position signal acquisition module and the drive module connected with it will be introduced separately below.

[0039] The four-arm compact converter includes 4 bridge arms connected in parallel, each bridge arm includes an upper bridge arm and a lower bridge arm connected in series, and the connection point between the upper bridge arm and the lower bridge arm is defined as the bridge arm at the same time as the output terminal of the converter, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com