Transformer real-time hot spot temperature prediction method

A technology of hot spot temperature and prediction method, which is applied in the direction of instruments, calculation models, artificial life, etc., and can solve the problem of difficult parameter selection of support vector machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

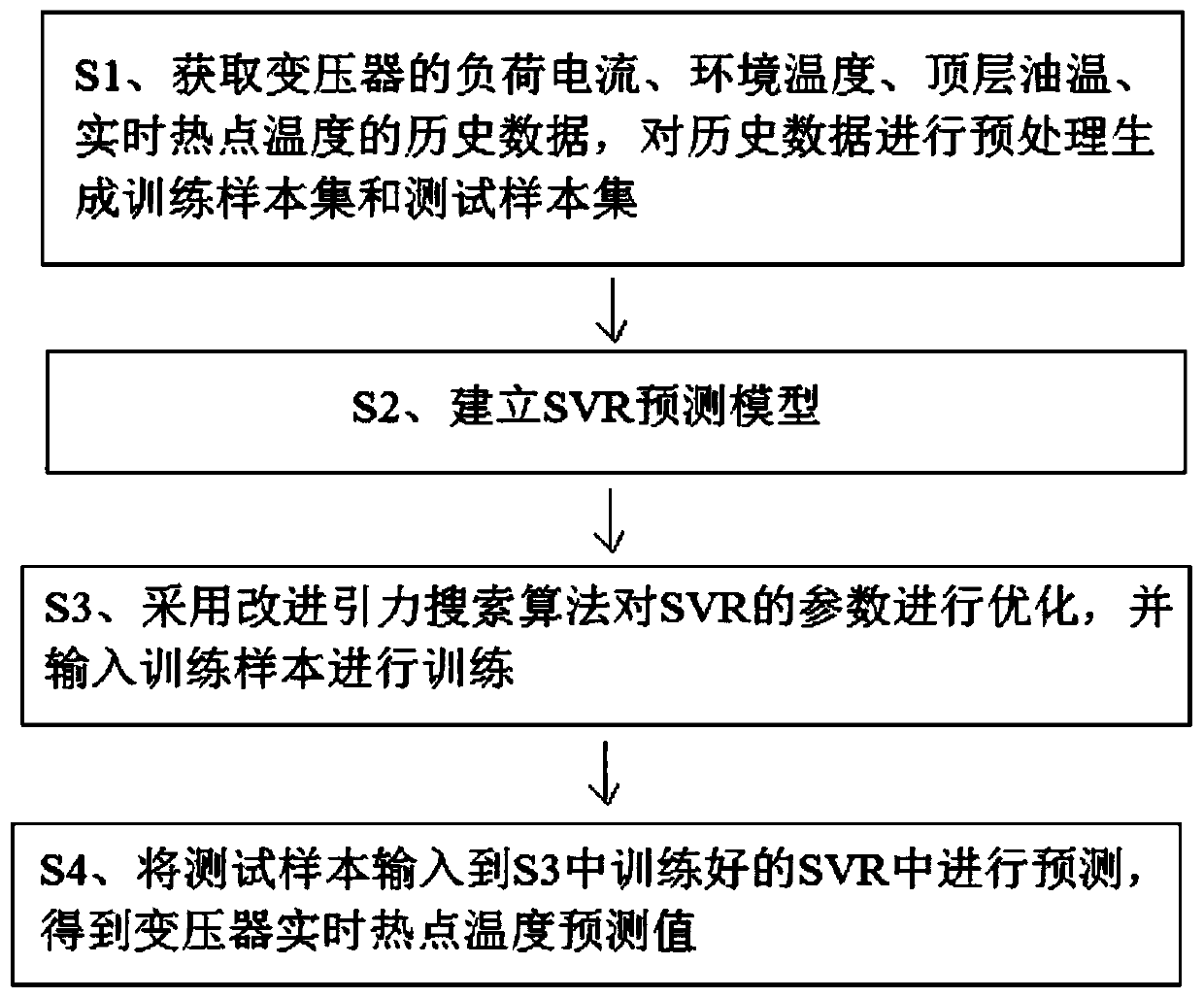

[0077] Such as figure 1 As shown, a transformer real-time hot spot temperature prediction method includes the following steps:

[0078] S1. Obtain the historical data of the transformer's load current, ambient temperature, top oil temperature, and real-time hot spot temperature, and preprocess the historical data to generate a training sample set and a test sample set;

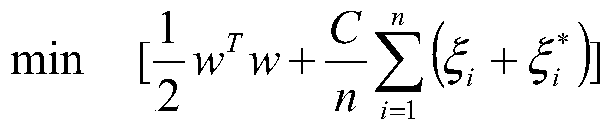

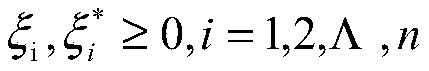

[0079] S2. Establishing an SVR prediction model;

[0080] S3, using the improved gravity search algorithm to optimize the parameters of the SVR, and input training samples for training;

[0081] S4. Input the test sample into the SVR trained in S3 for prediction, and obtain the real-time hot spot temperature prediction value of the transformer.

[0082] In this embodiment, the historical data is acquired in step S1, and the process of preprocessing the historical data to generate a training sample set and a test sample set is as follows:

[0083] The characteristic parameters of the transformer include: loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com