Monitoring and cleaning early warning method of heat exchanger group operating condition based on dynamic envelope method

A dynamic envelope and operating status technology, applied in the direction of instrumentation, forecasting, data processing applications, etc., can solve the problem that there is no complete system and method for monitoring and cleaning early warning of heat exchanger groups in large petrochemical plants , to achieve long-term operation, reduce maintenance costs, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

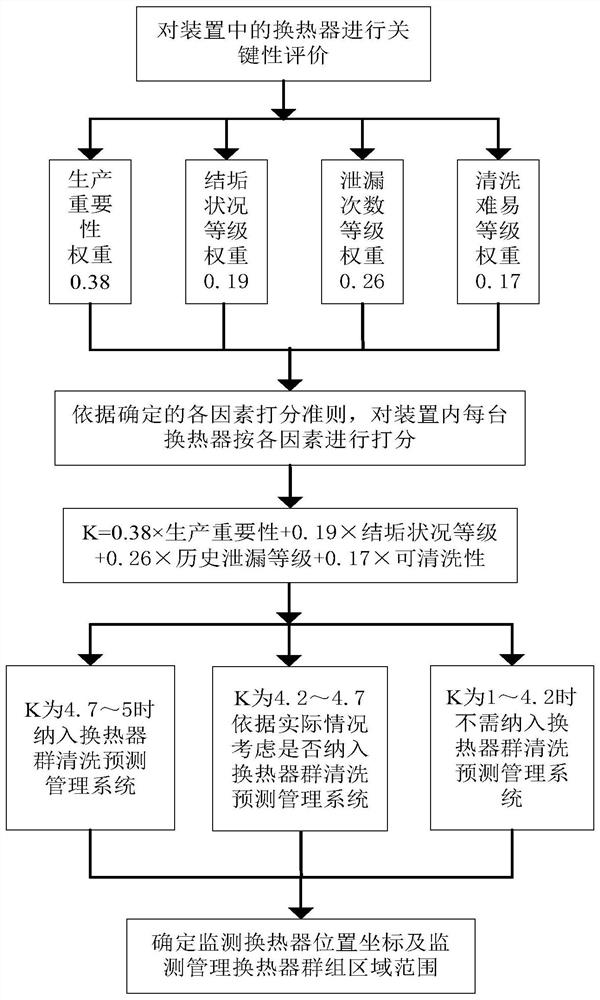

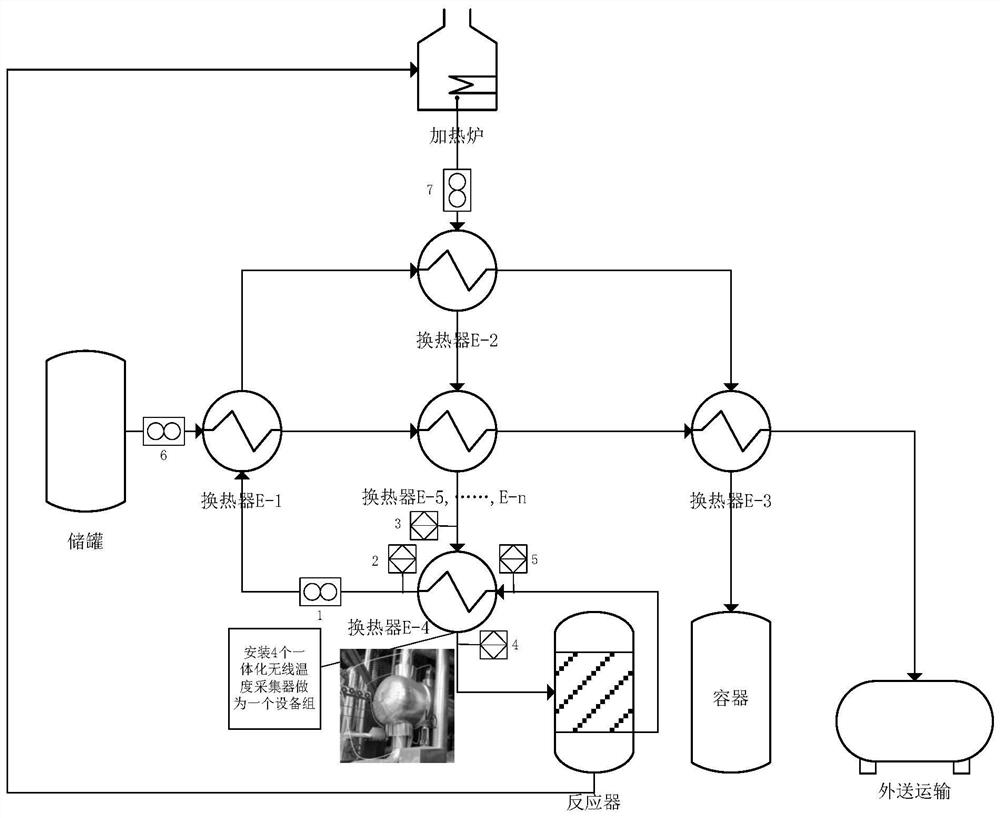

[0021] The following describes in detail the method for monitoring, cleaning and early warning of the operation condition of the heat exchanger group based on the dynamic envelope method of the present invention with reference to the embodiments and the accompanying drawings.

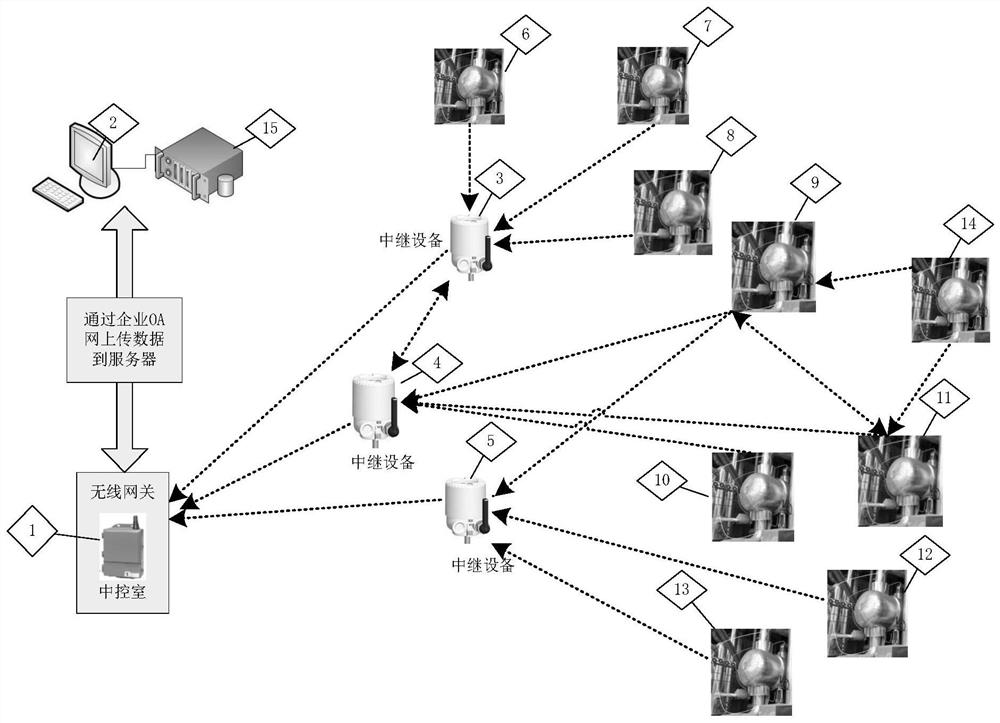

[0022] The method of monitoring and cleaning the early warning of the operation condition of the heat exchanger group based on the dynamic envelope method of the present invention is to use such as figure 1 and figure 2 Shown is a method for a real-time monitoring system for the heat exchange efficiency of a heat exchanger in a large petrochemical plant. The monitoring results of the operating status of the heat exchanger are mainly affected by two factors, system factors and random factors. During the operation of the heat exchanger, the present invention focuses on the stability of the operating status and whether it is normal or not. If there are large variable system influence factors or large ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com