Nuclear fuel assembly and variable-rigidity pressing device

A nuclear fuel assembly and compression device technology, which is applied in the assembly of fuel elements, reactor fuel elements, nuclear engineering, etc., can solve the problems of insufficient compression force, large amount of irradiation relaxation, large stress of spring sheets, etc., to reduce bending risk, reducing creep relaxation, eliminating the effects of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

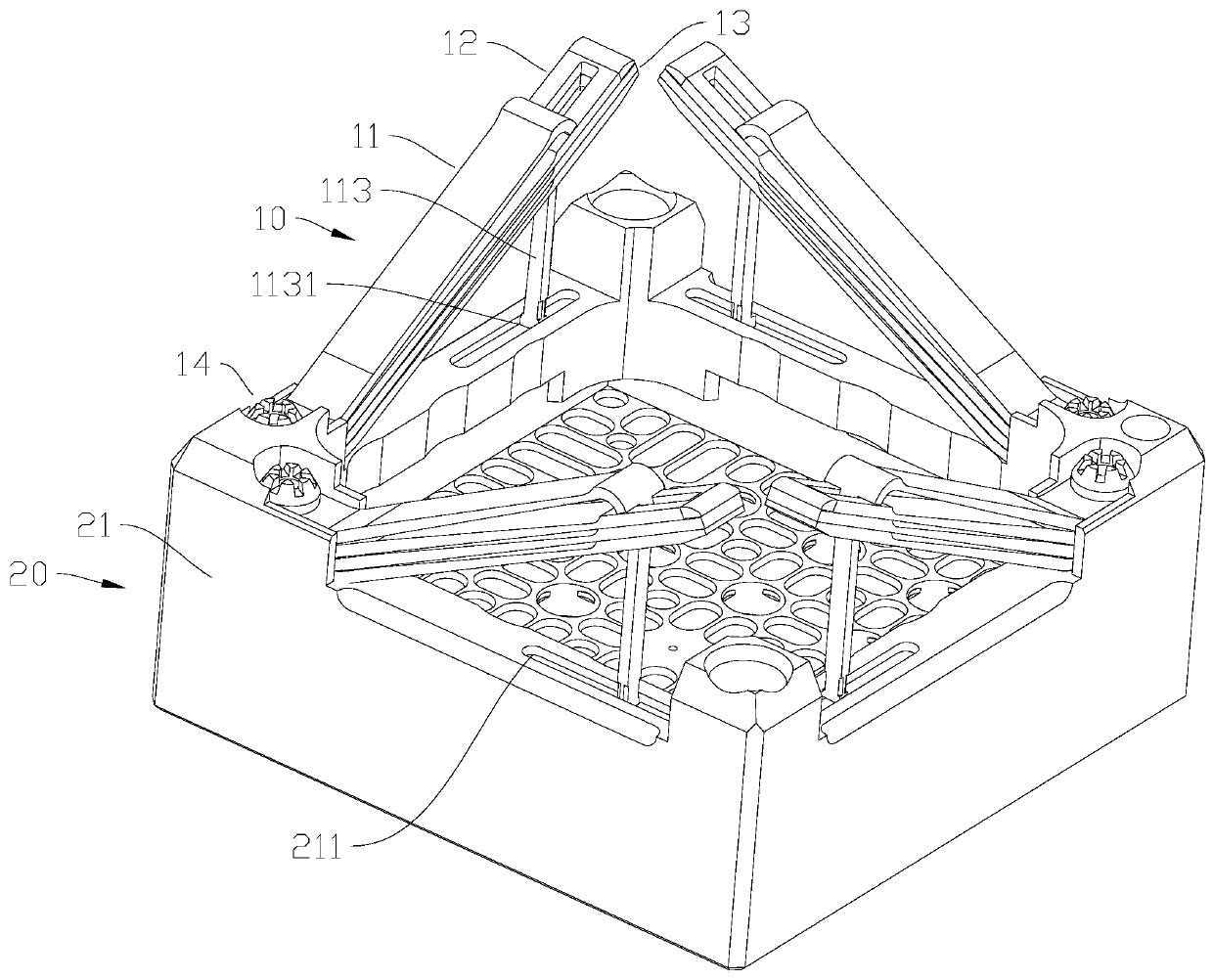

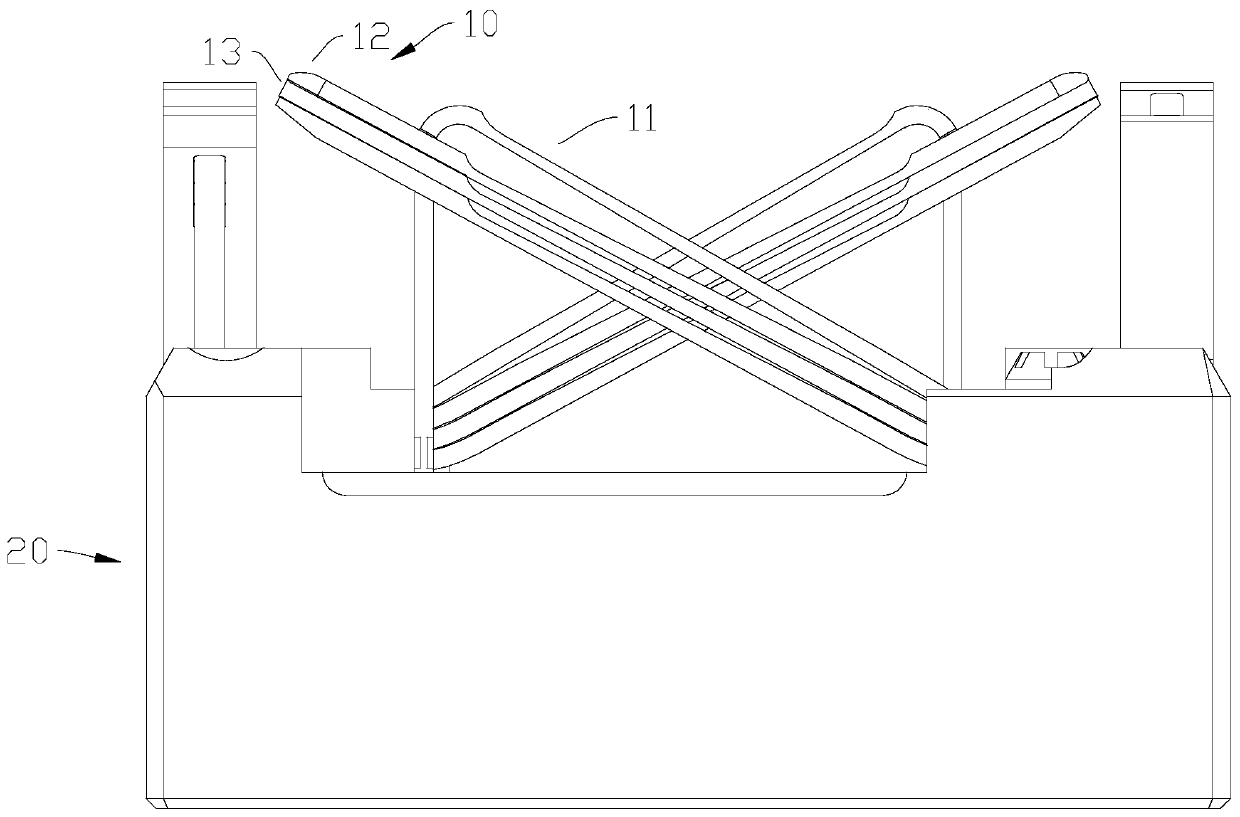

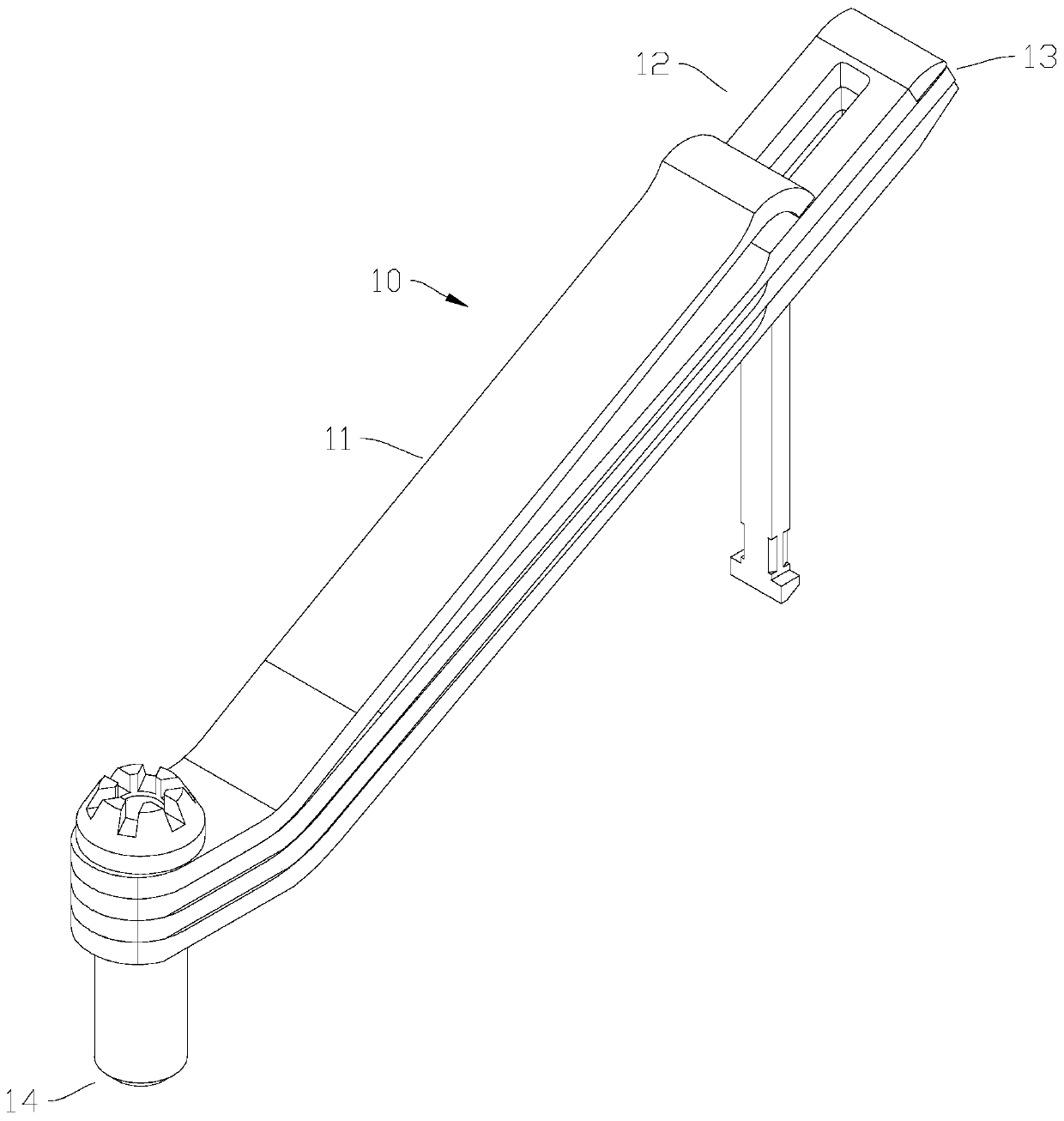

[0046] figure 1 and figure 2 Some preferred embodiments of the fuel assembly of the present invention are shown. The fuel assembly can be placed in a pressurized water reactor, which can avoid the risk of insufficient compaction force at the later stage of operation, and has the advantage of high safety performance. The pressing device in the fuel assembly of the present application adopts the design of variable stiffness according to the different requirements for the pressing force of the plate spring under the cold and hot states to achieve the purpose of obtaining an appropriate pressing force margin under different working conditions. It effectively alleviates the problems of excessive compression force margin u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com