Use of a q&p steel for producing a shaped component for high-wear applications

A technology for uses and components, applied in the field of forming components, which can solve problems such as inability to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

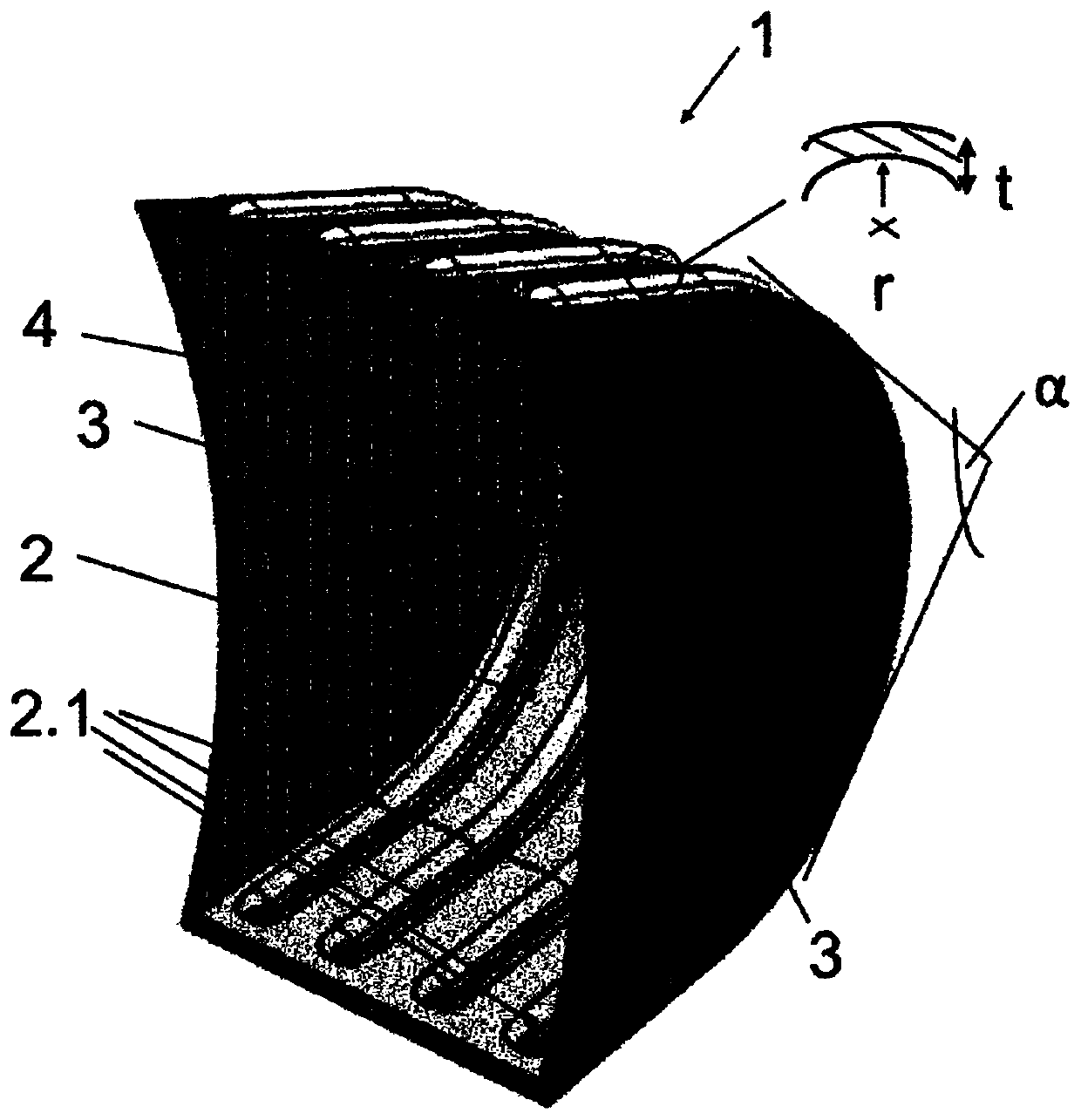

[0045] In the single figure, the excavator bucket (1) is shown in section. The excavator bucket (1) is, for example, a welded structure composed of three components (2, 3), consisting of a complexly shaped half shell (2) and two The side assembly (3) serves to create a cavity (4) open to one side for receiving waste material not shown. Along the partial circumference of the half shell (2), four embossments (2.1) running parallel to one another are formed, in particular for reinforcing the excavator bucket (1). Compared with the half shell without embossing, under the same performance, the material thickness (t) of the half shell (2) can be reduced by forming the embossing (2.1), so that the total weight of the excavator bucket (1) The weight is reduced and the loading capacity of the maximum allowable load of the excavator boom can be increased.

[0046] Components or half-shells (2) consist of Q&P steel which, in addition to Fe and production-induced unavoidable impurities,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com