Integrated steamed stuffed bun raw material producing and processing machine

A processing machine and raw material technology, which is applied in the field of steamed stuffed bun raw material integrated production and processing machines, can solve the problems of increasing cost, increasing the speed of making steamed stuffed buns, increasing production capacity, etc., and achieves the effects of beating and kneading evenly, improving experience and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

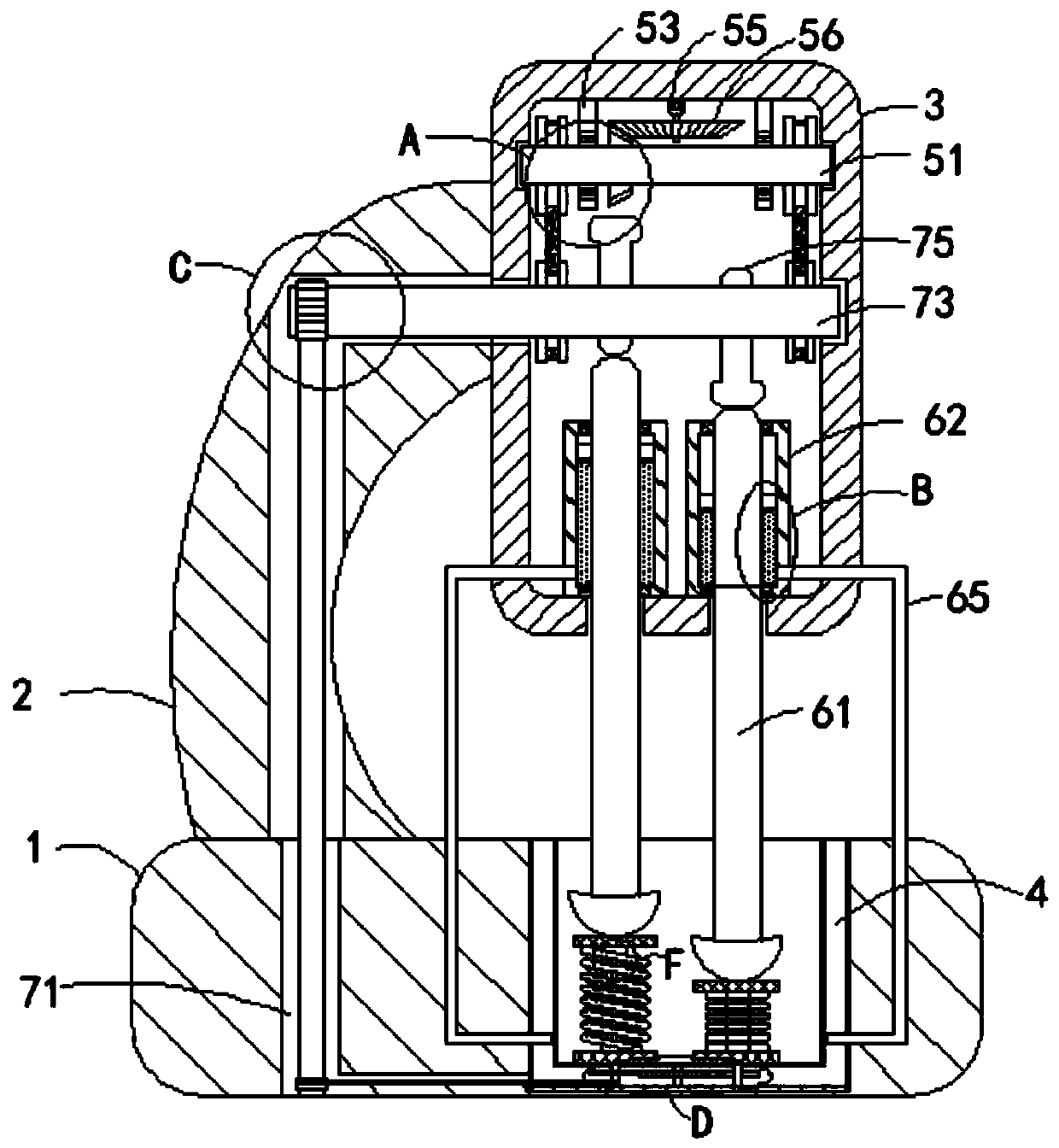

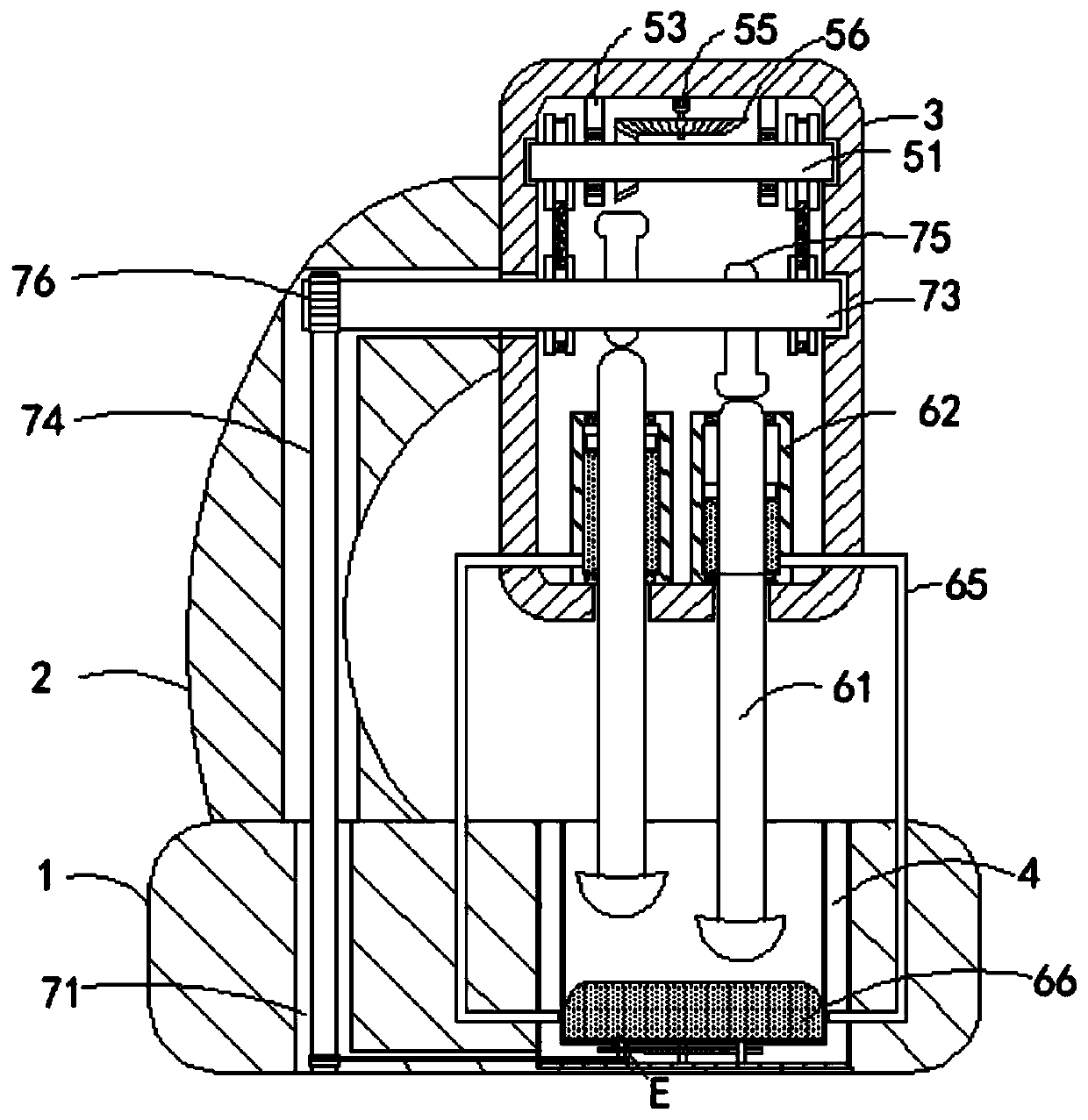

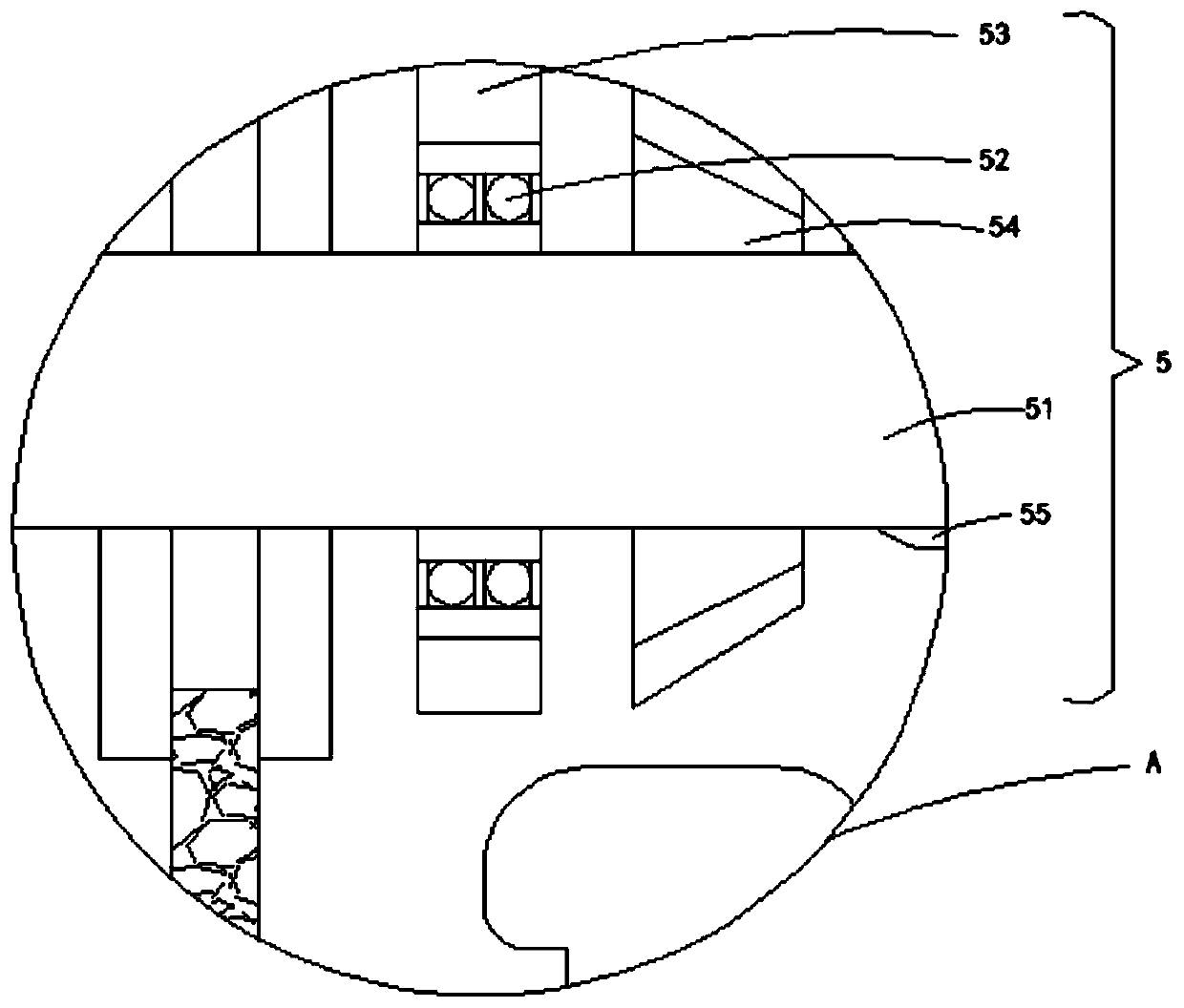

[0028] refer to figure 1 , an integrated production and processing machine for bun raw materials, comprising a base 1, a load-bearing column 2 is fixedly installed on the upper end of the base 1, the load-bearing column 2 provides support for the base 1, an installation box 3 is fixedly connected to the load-bearing column 2, and the base 1 is equipped with There is a processing tank 4, the top surface of the inner wall of the installation box 3 is provided with a driving mechanism 5, the bottom of the inner wall of the installation box 3 is provided with a kneading mechanism 6, the bottom of the kneading mechanism 6 is located in the processing tank 4, and the driving mechanism 5 passes through the transmission mechanism 7 It is connected with the kneading and extruding mechanism 6, and the inner wall of the processing tank 4 is provided with a deceleration mechanism 8, and the end of the transmission mechanism 7 away from the kneading and extruding mechanism 6 is connected wi...

Embodiment 2

[0035] The second auxiliary assembly 10 includes two I-shaped plates 101 arranged in the processing tank 4. The vertical parts of the two I-shaped plates 101 are coaxially fixedly connected with strip-shaped springs 102, and the surface of the springs 102 is equipped with broken The tooth 103 and the spring 102 are arranged on the I-shaped plate 101 in order to reset the movement of the impact hammer 61, and the crushing tooth 103 on the spring 102 can carry out deep crushing processing on the bun stuffing during the movement of the spring 102. The spaces are arranged alternately, and the lower end of the horizontal part of the I-shaped plate 101 is fixedly connected with a screw rod 104 , and the screw rod 104 is screwed with the nut 92 .

[0036] In the invention, the baffle plate 93 is installed on the bottom of the processing tank 4, the motor 55 is turned on, the output shaft of the motor 55 rotates, the direction of motion is changed through the transmission connection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com