A processing device for a winding roller brush

A processing device and winding technology, applied in the direction of brushes, brush bodies, cleaning methods and utensils, etc., can solve the problems of low processing efficiency, poor winding effect, unsightly appearance, etc., achieve convenient installation and disassembly, and improve processing quality , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

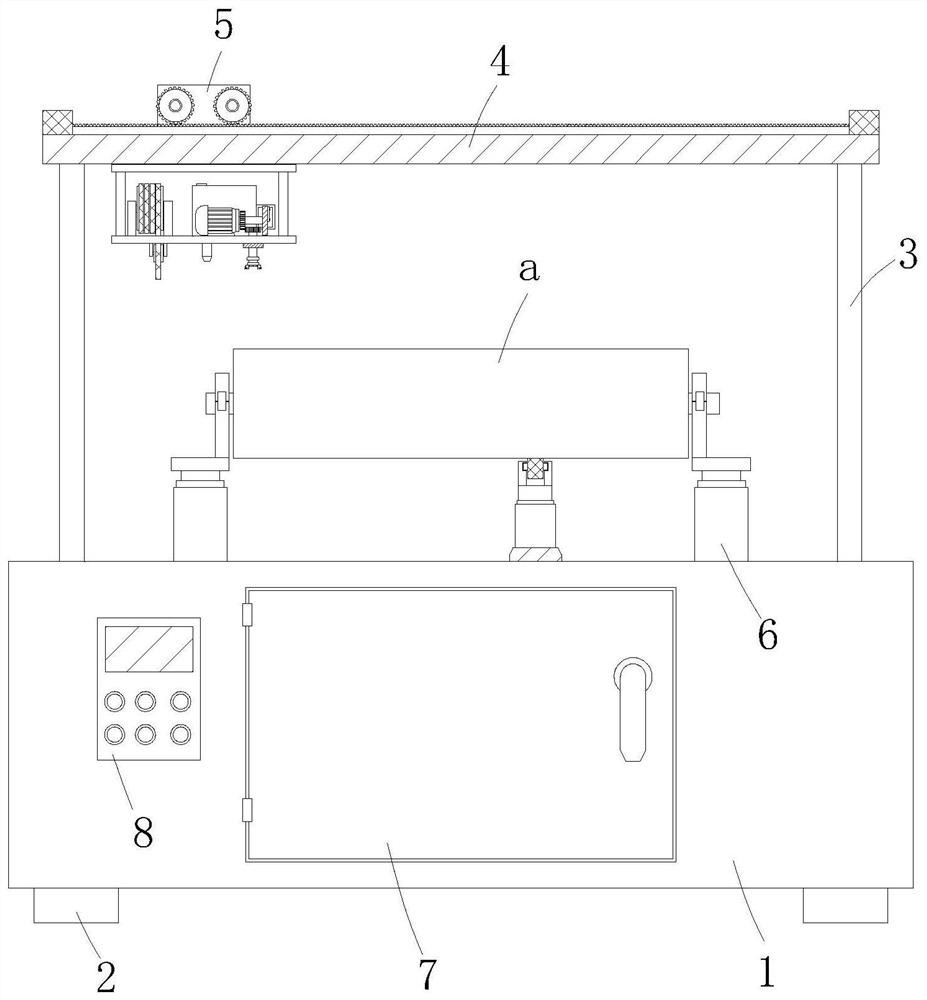

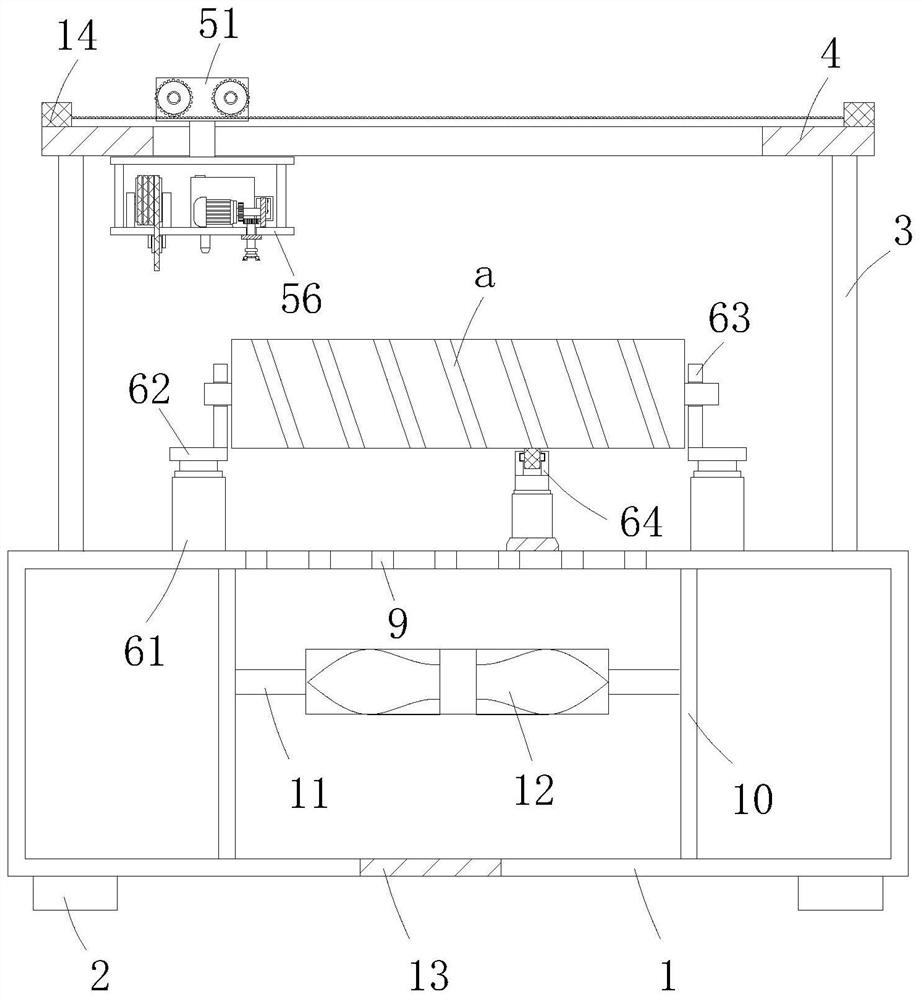

[0043] A processing device for a winding roller brush, comprising a base box 1 and a plurality of supporting feet installed at the lower end of the base box 1, and the upper end of the base box 1 is provided with two side panels 3 and a top panel 4 at the upper end of the side panel 3 frame, the lower end of the top plate 4 is equipped with a processing mechanism 5 for winding rolling brush processing, the upper end of the base box 1 is provided with a brush roller support mechanism 6 at a position below the processing mechanism 5, and the upper end of the brush roller support mechanism 6 A brush roll a as a processing base material is provided;

[0044] The processing mechanism 5 includes two traveling rails 53 symmetrically installed on the upper end of the top plate 4, and the traveling rails 53 are rollingly mounted with two traveling wheels 52, wherein the two traveling wheels are mounted on the same stepper motor 54 through the first transmission mechanism. on the output...

Embodiment 2

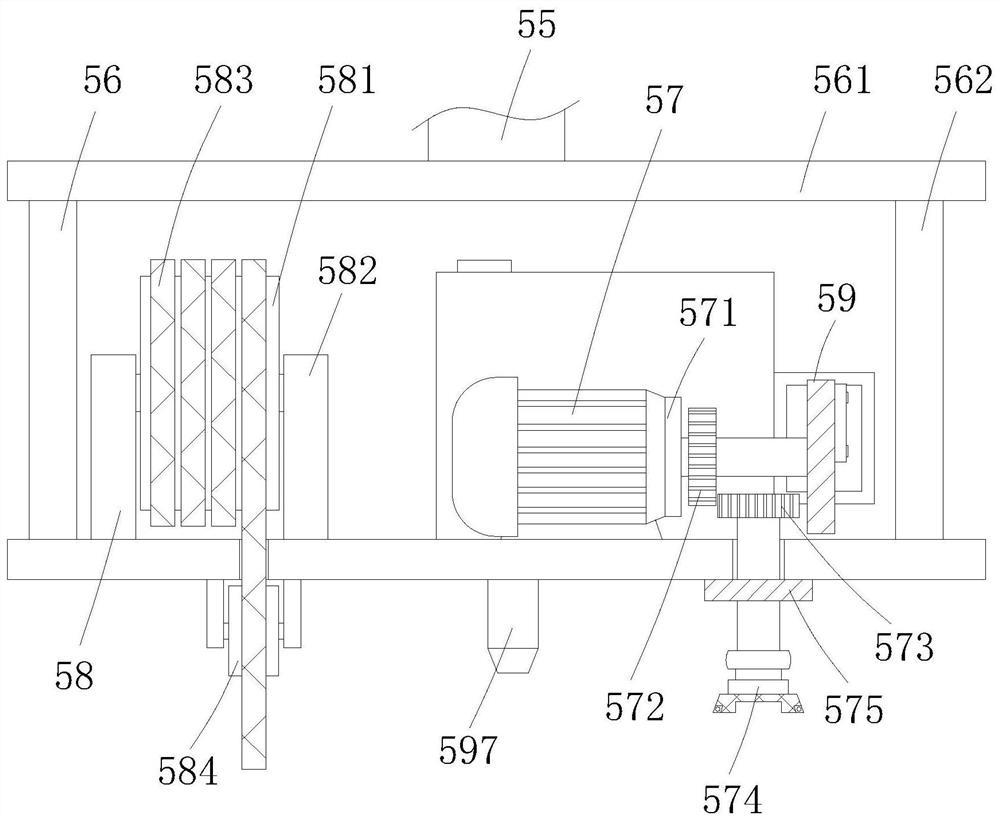

[0059] The difference between this embodiment and embodiment 1 is that, as image 3 with 4 As shown, the mounting frame 56 is also provided with a gluing assembly 59, the gluing assembly 59 includes a turntable 595 installed on the output end of the servo motor 571, and the edge of the turntable 595 facing away from the side of the servo motor 571 is rotated and installed with a connecting rod. Rod 594, the other end of connecting rod 594 extends to the inner chamber of installation sleeve 592 and is hinged with piston 593, and piston 593 is slidably installed on the inner wall of installation sleeve 592, and piston 593 and the inner chamber rear wall of installation sleeve 592 There is an elastic member 596 between them, the installation sleeve 592 is fixedly installed on the side wall of the plastic box 591, and the end of the installation sleeve 592 is connected with the plastic box 591, and the plastic box 591 is fixedly installed on the inner bottom wall of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com