Wood strip grinding device with feeding mechanism and using method thereof

A technology of wooden strips and racks, applied in the field of wooden door processing equipment, can solve the problems of high labor intensity and low production efficiency of workers, and achieve the effects of saving grinding time, improving work efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0044] The technical scheme of the present invention is only applicable to the wooden strips with a square cross-section, and is not applicable to wooden strips of other shapes, and can only be polished to wooden strips of the same size.

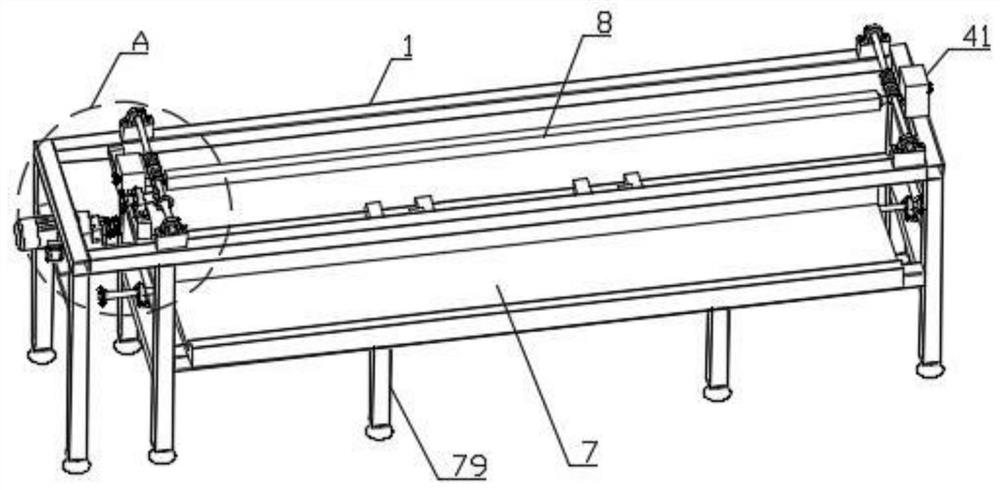

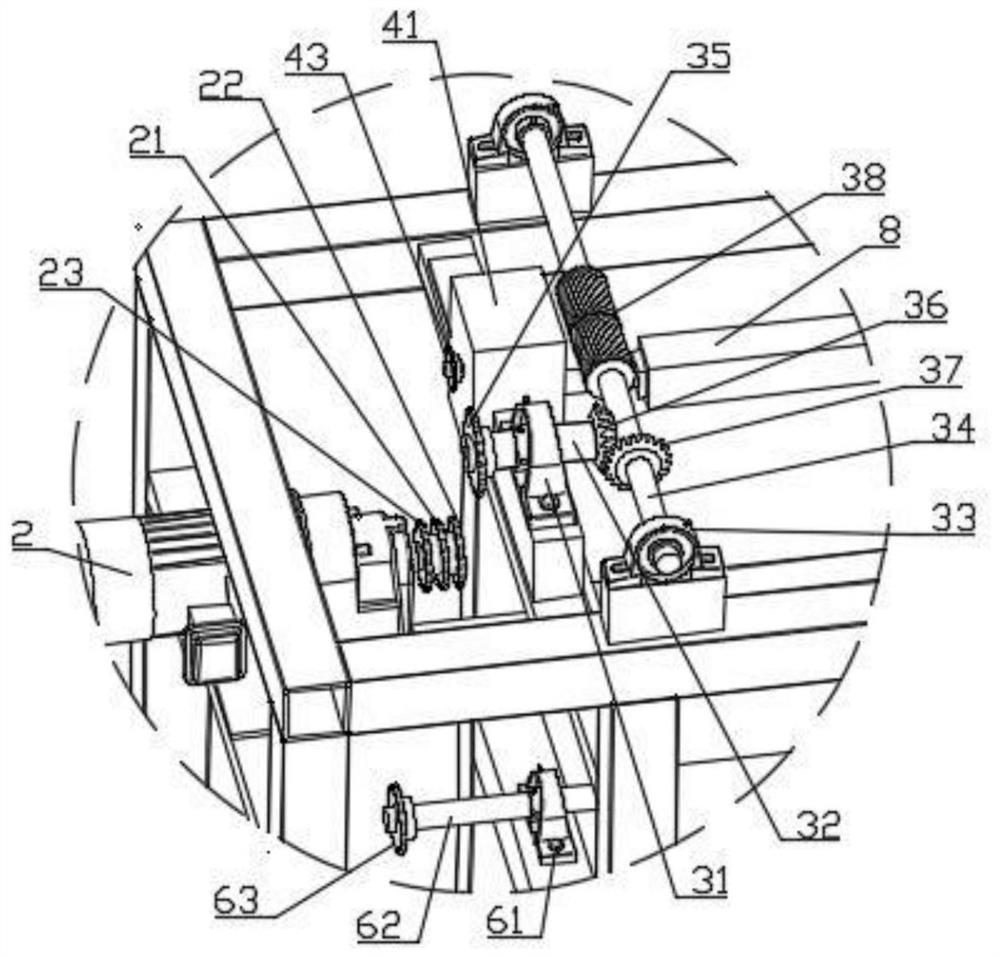

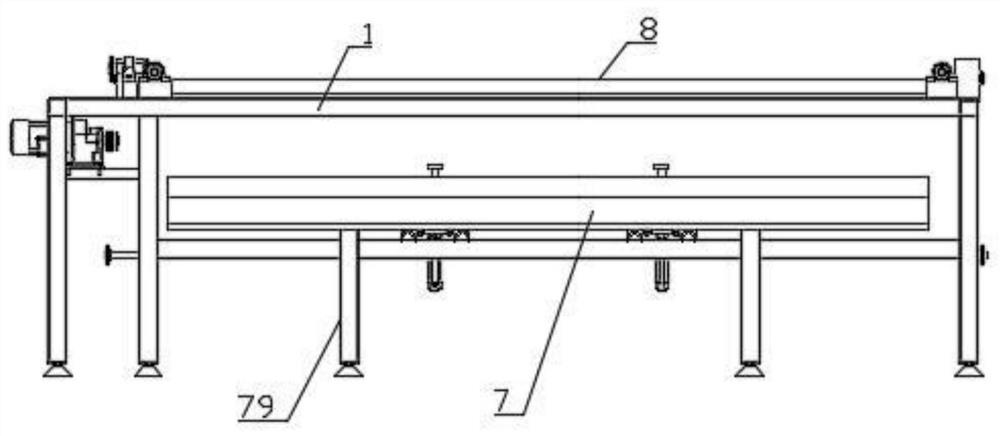

[0045] Such as Figure 1 to Figure 11 As shown, a wood strip grinding device with a feeding mechanism of the present invention includes a frame 1, which is welded by square steel pipes or channel steel, and the left and right ends of the frame 1 are provided with supporting legs.

[0046] In order to realize automatic feeding, a feeding mechanism 7 is installed on the frame 1, and the feeding mechanism 7 includes a housing 71 again, and the rear end of the housing 71 (i.e. Figure 11 The bottom of the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com