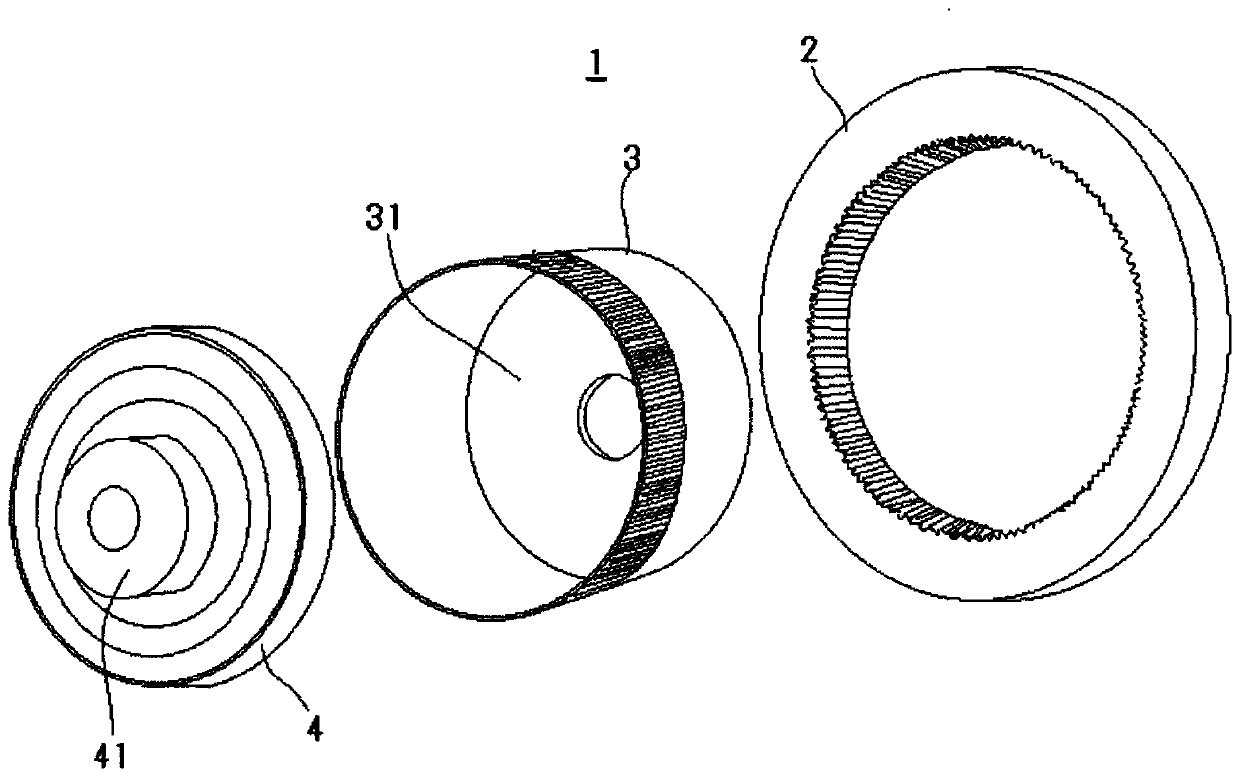

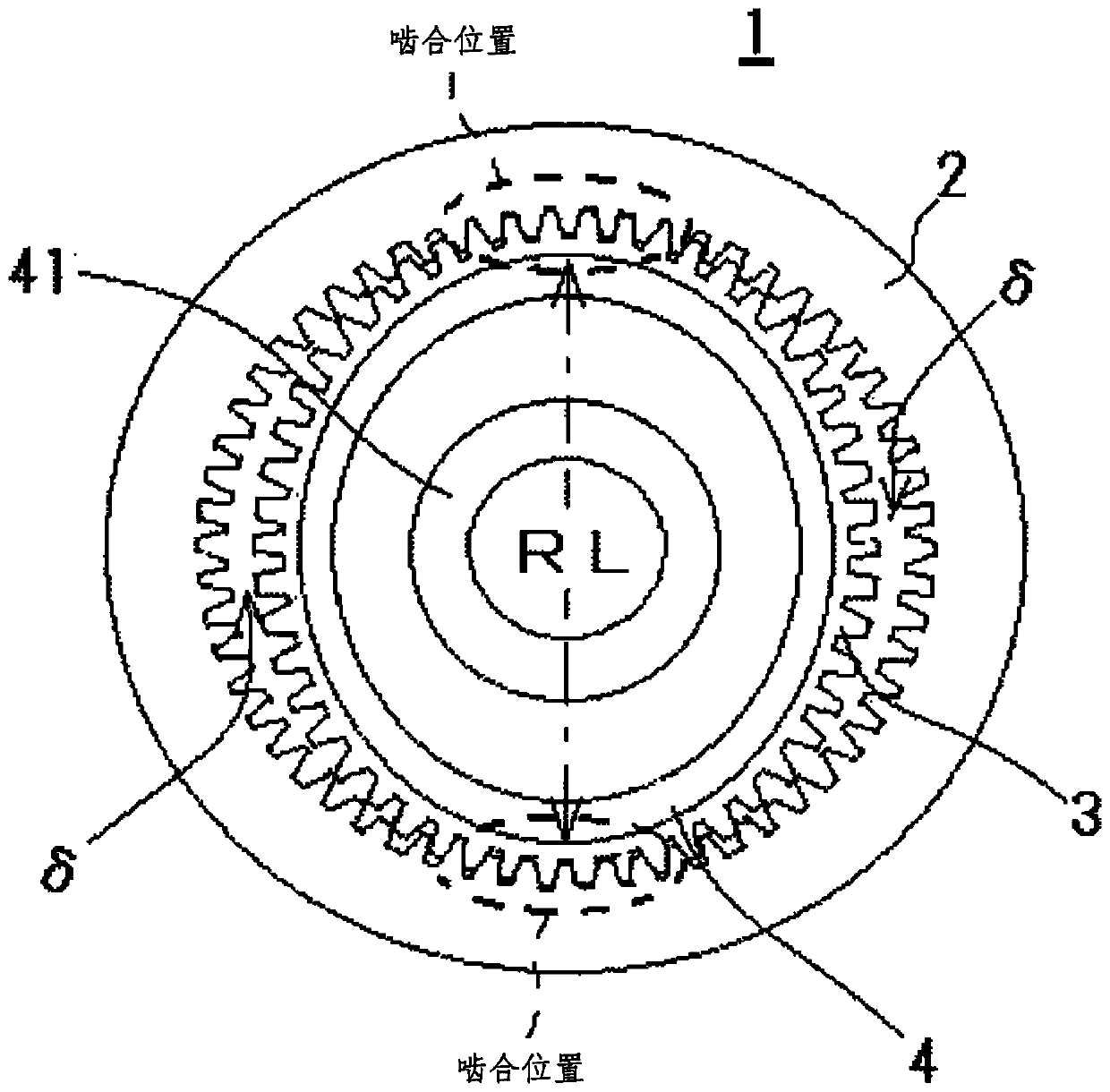

Surface treatment method of gear for wave reduction gear mechanism

一种减速齿轮、表面处理的技术,应用在外齿齿轮领域,能够解决塑性变形性降低、无法取得机械强度、加工困难等问题,达到齿轮寿命延长、安静操作噪音、实现消声效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Test purposes

[0101] Differences in the respective surface states of external gears used in wave reduction gear mechanisms formed of different materials were confirmed for the case of surface treatment of external gears using the method of the present invention (first process and second process) The case of ; the case of only the shot peening corresponding to the second process of the present invention for the external gear; and the case of no treatment.

[0102] processing conditions

[0103] processing object

[0104] Externally toothed gears (each heat-treated product with a diameter of 60 mm) for a wave reduction gear mechanism were prepared as processing objects. External gears are made of SCM435H (0.32%-0.39% carbon content), SCM440H (0.37%-0.44% carbon content) and SNCM439 (0.36%-0.47% carbon content).

[0105] Jetting conditions

[0106] The particle ejection conditions are given in Table 3 below.

[0107] table 3

[0108]

[0109] Materials and Treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com