Industrial robot hand-eye calibration method based on calibration ball

A technology of industrial machines and calibration methods, applied in the field of 3D vision, can solve the problems of low precision, time-consuming and laborious, cumbersome and other problems, and achieve the effect of high precision, ensuring reliability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

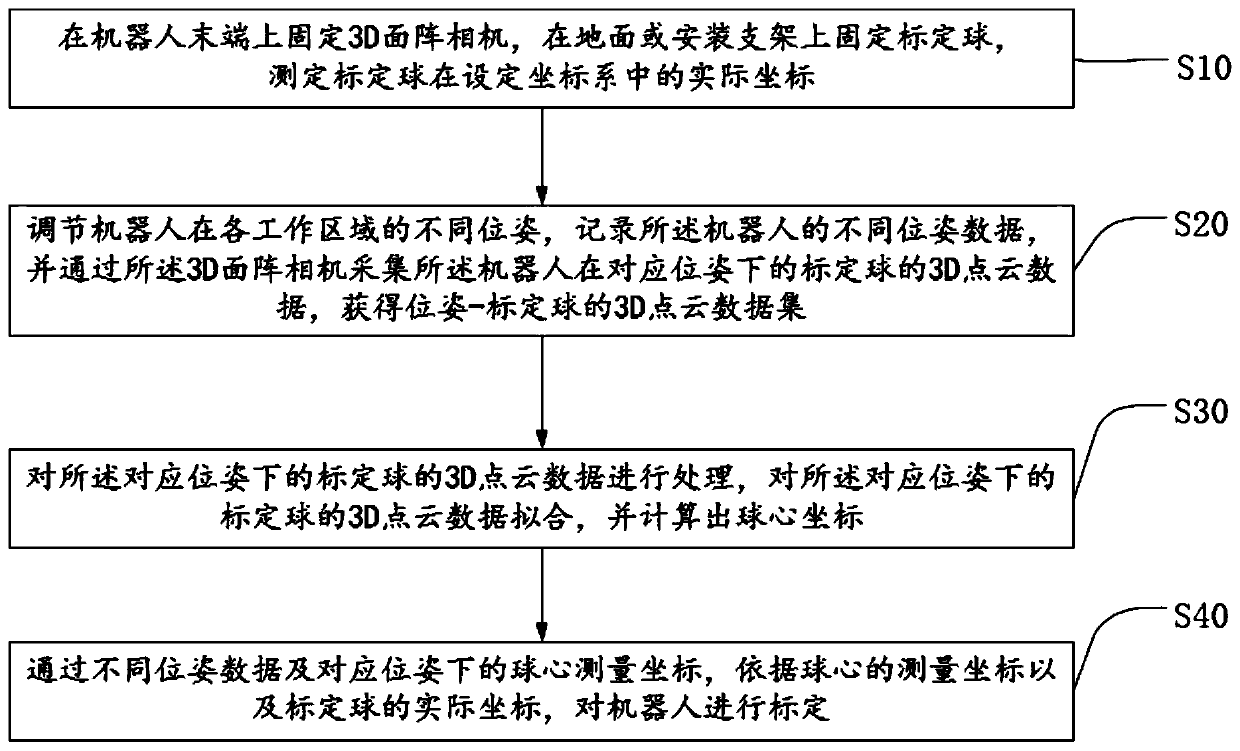

[0025] refer to Figure 1-Figure 2 As shown, the present invention discloses a hand-eye calibration method for an industrial robot based on a calibration ball, comprising the following steps:

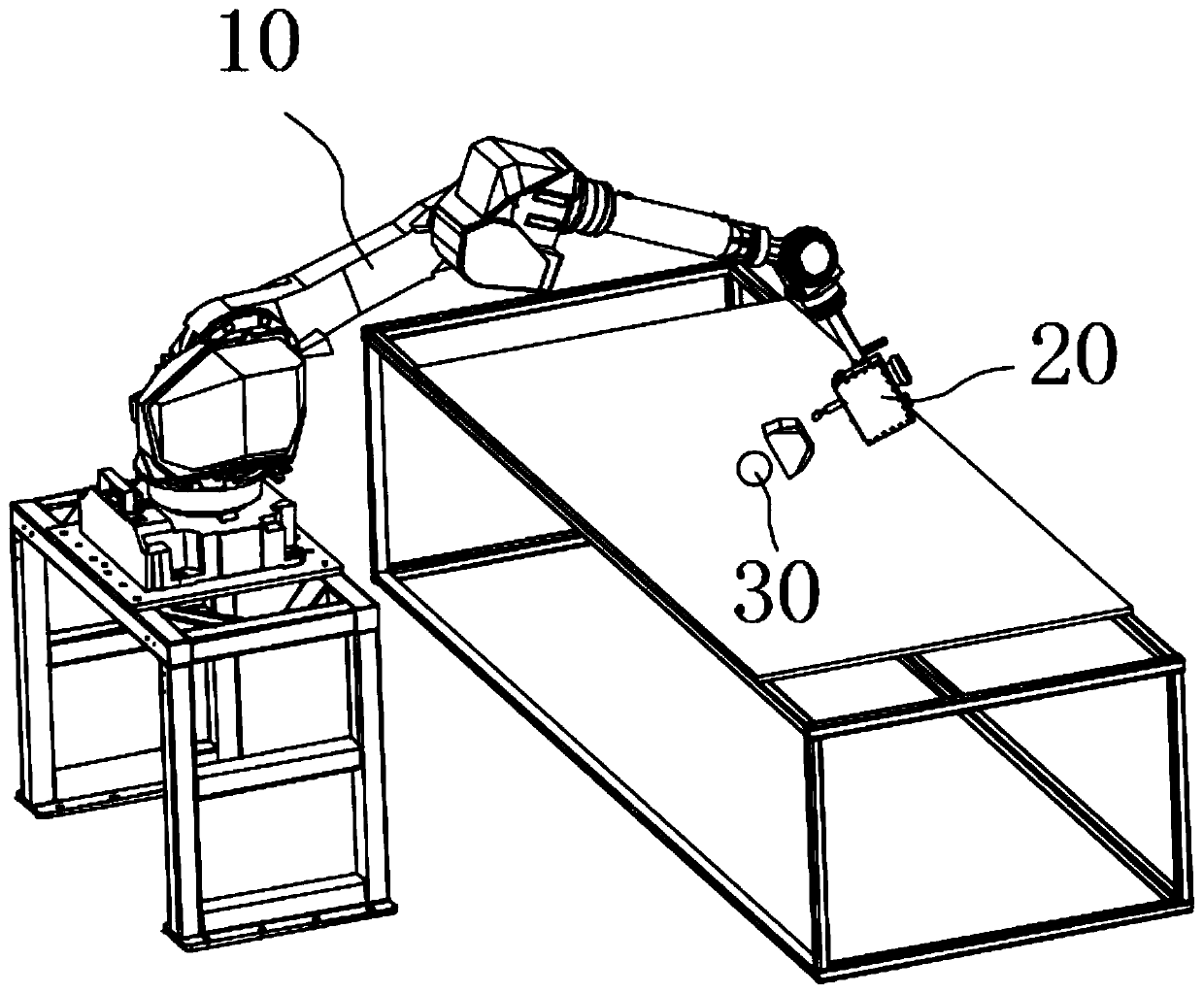

[0026] Step 1: Fix the 3D area camera 20 on the end of the robot 10, fix the calibration ball 30 on the ground or on the mounting bracket, and measure the actual coordinates of the calibration ball in the set coordinate system. The calibration ball is a ceramic positioning ball. The ceramic positioning ball is fixed on the ground through a mounting bracket.

[0027] Step 2, adjusting the different poses of the robot in each working area, recording the different pose data of the robot, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com