A kind of colored matte flame-retardant polyester film and preparation method thereof

A technology of flame-retardant polyester and matte color, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc. It can solve the problems of non-matteness, poor flame retardancy and single color of single-function BOPET base film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

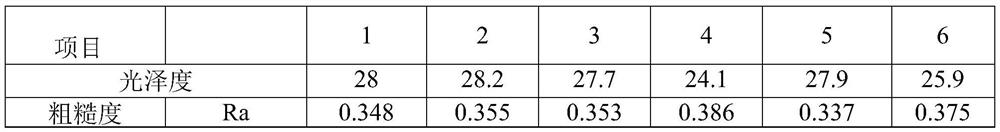

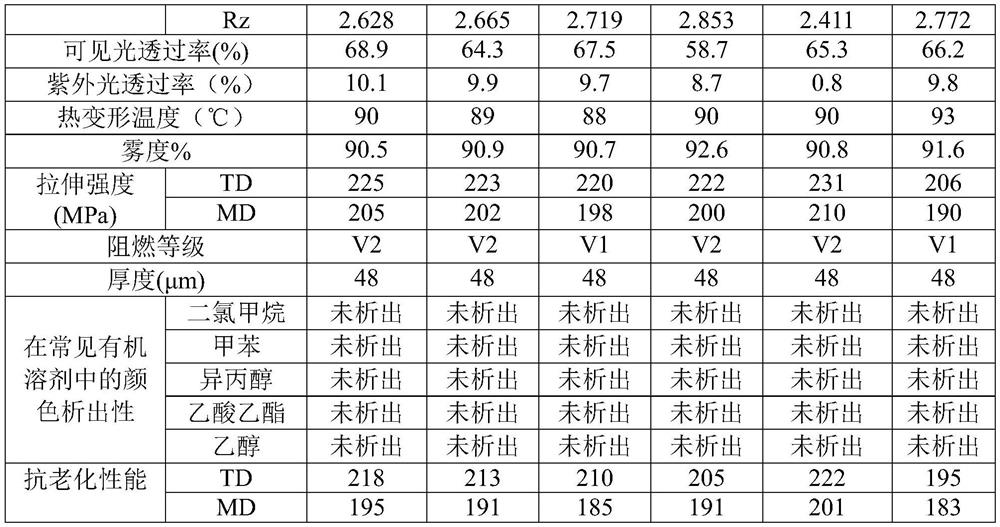

Embodiment 1

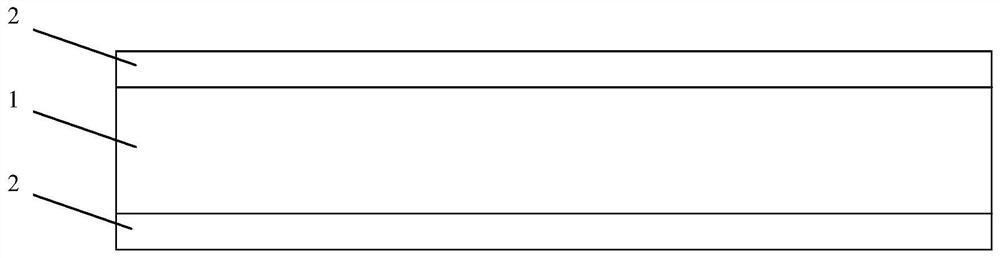

[0061] Provide a kind of colored matte flame retardant polyester film, comprise core layer, the both sides of described core layer (A layer) are provided with matte layer (B layer) respectively; Described core layer contains phosphorus flame retardant, so The matte layer contains BaSO 4 particles.

[0062] The method for preparing above-mentioned colored matte flame-retardant polyester film, comprises the steps:

[0063] (1) Add transparent optical grade PET slices into a pulverizer to grind polyester powder with a particle size of 0.4 μm to 0.5 μm, and then mix PET powder, flame retardant powder, green pigment powder, dispersant, and antioxidant according to Mass fractions of 62%, 25%, 10%, 2.5%, and 0.5% were added to the agitator, stirred at a high speed of 3000r / min at room temperature for 8 minutes, then reduced to 180r / min and stirred for 4 minutes, and finally the mixed raw materials were placed in the Melt extrusion and granulation under the temperature of 275-285 ℃ ...

Embodiment 2

[0071] For the colored matte flame-retardant polyester film provided in Example 1, the difference between this embodiment and Example 1 is that polyester powder, flame-retardant powder, green pigment powder, dispersant, and antioxidant in the green flame-retardant masterbatch The mass fractions are 57%, 25%, 13%, 4.9%, 0.1%, respectively.

Embodiment 3

[0073] For the colored matte flame-retardant polyester film provided in Example 1, the difference between this embodiment and Example 1 is that the flame-retardant masterbatch is a purple flame-retardant masterbatch, and the polyester powder and flame-retardant in the purple flame-retardant masterbatch The mass fractions of powder, purple pigment powder, dispersant, and antioxidant are 52%, 35%, 10%, 2.5%, and 0.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com