A transfer device for silicon wafer processing

A technology for transfer devices and silicon wafers, which is applied in the directions of transportation and packaging, trolley accessories, multi-axis trolleys, etc., can solve the problems of increasing the working efficiency of the staff and inconvenient use, and achieve the goal of increasing the fixed speed, being easy to use, and reducing the workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

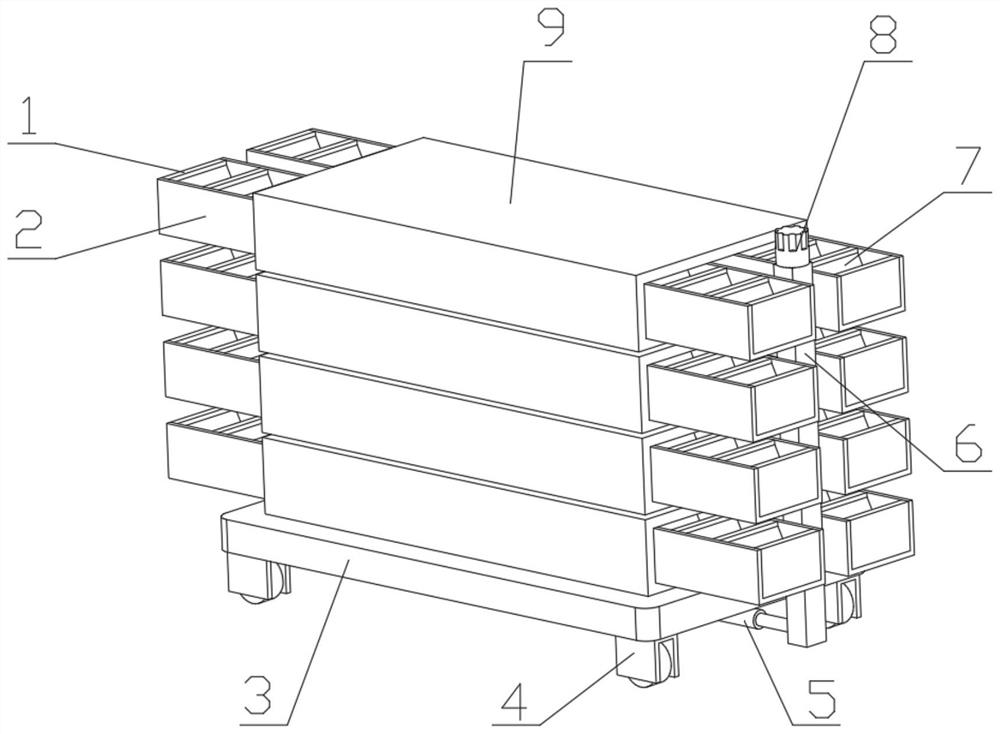

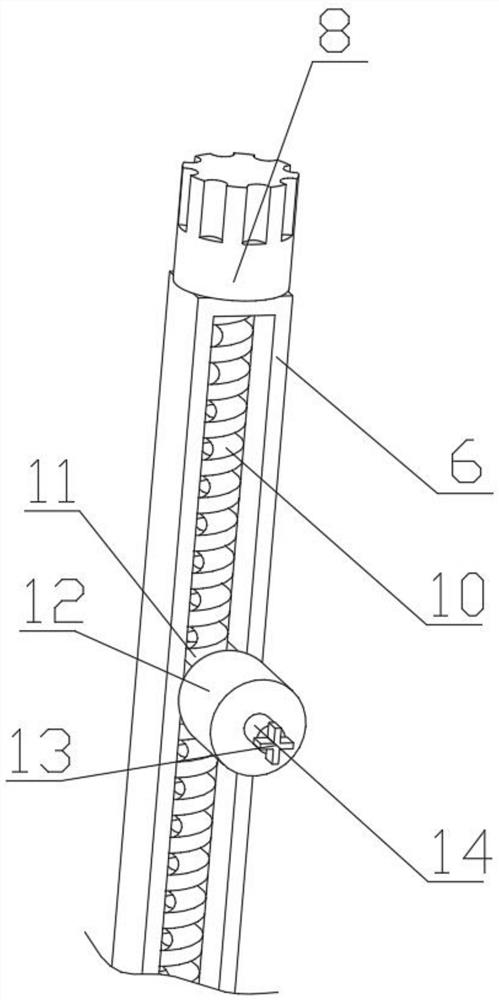

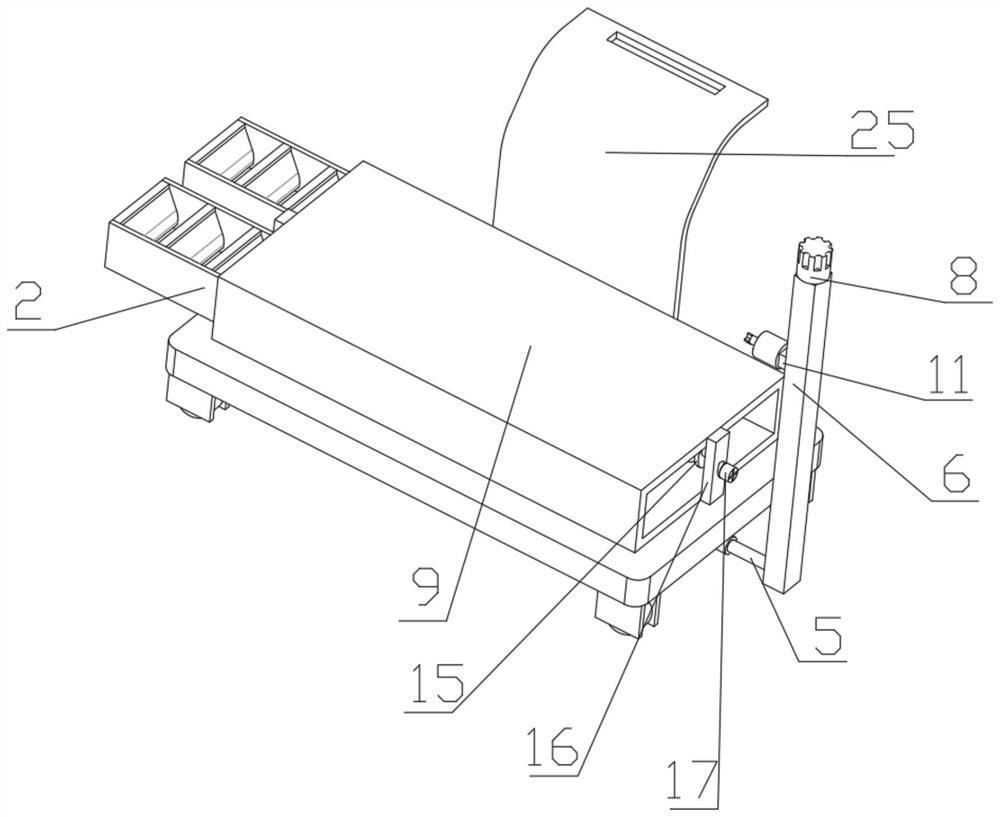

[0029] refer to Figure 1-5 , a transfer device for silicon wafer processing, comprising a base 3, the outer wall of the top of the base 3 is equipped with storage shells 9 equidistantly distributed, and the outer walls of both sides of the storage shell 9 are equipped with fixed blocks 16, and the two fixed blocks 16 are opposite to each other. One side of the outer wall is rotatably connected with the same two-way screw rod 15, and both sides of the circumference outer wall of the two-way screw rod 15 are connected with the first sliding block through screw thread rotation, and the outer walls at both ends of the first sliding block are equipped with a storage case 2. A rubber pad 21 is installed on the inner wall of the bottom of the housing 2, and the outer wall of the top of the rubber pad 21 is equipped with partitions 1 distributed equidistantly, and the top of the outer wall on the opposite side of the adjacent two partitions 1 is hinged with an extrusion plate 7, and t...

Embodiment 2

[0033] refer to Figure 1-6 , a transfer device for silicon wafer processing, which also includes a label holder 23 installed on the outer wall of one end of the storage housing 9, and equidistantly distributed stoppers 24 are installed on the inner wall of the bottom of the label holder 23.

[0034] Working principle: Compared with Embodiment 1, by setting the stopper 24 and the label rack 23, the stored silicon wafers can be recorded, which is convenient for staff to check and people to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com