Efficient cooling industrial furnace

An industrial furnace, high-efficiency technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve the problems of poor uniformity and stability, short service life of the furnace, low cooling efficiency, etc., and achieve low cost, cost reduction, and cooling efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

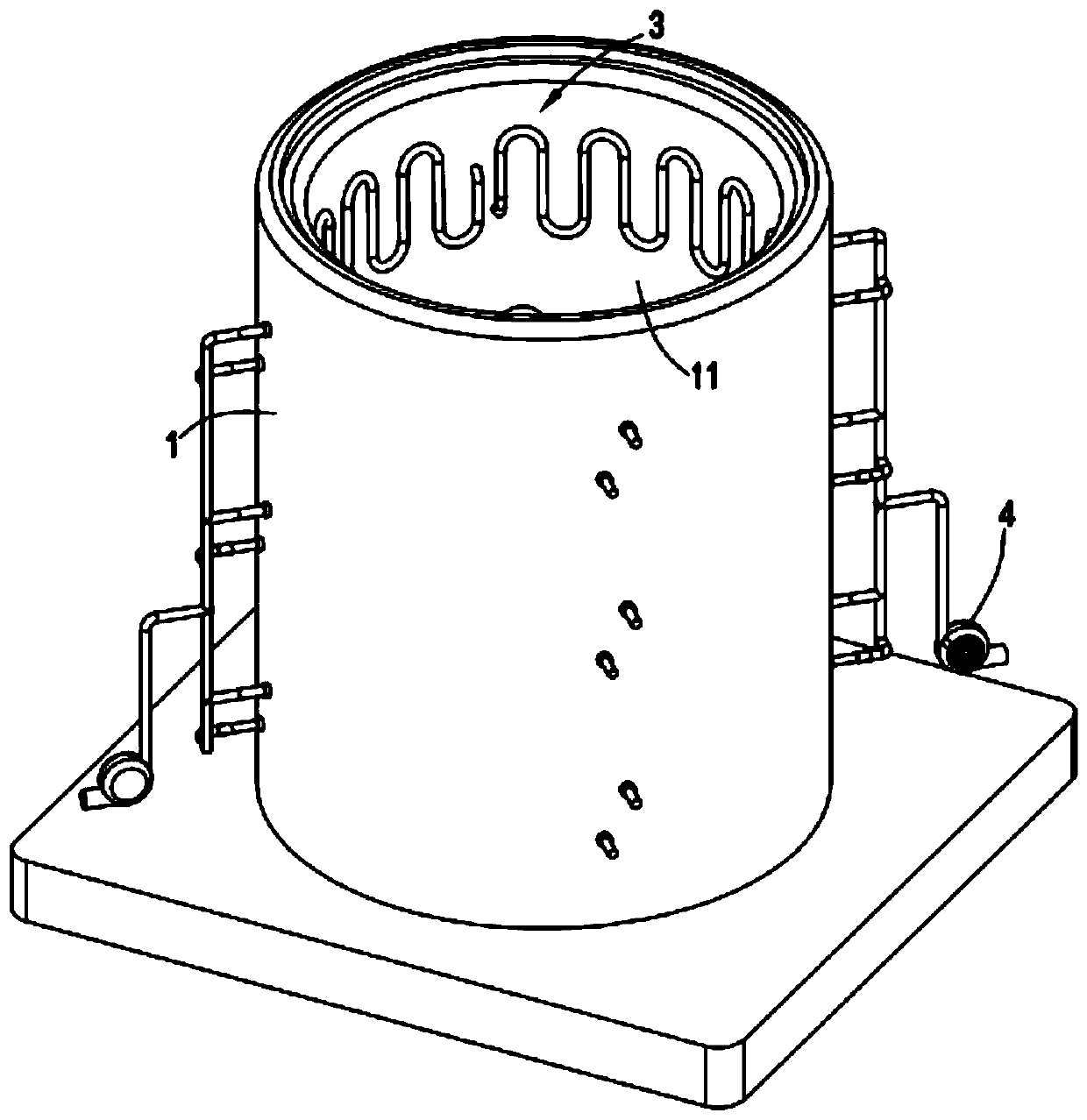

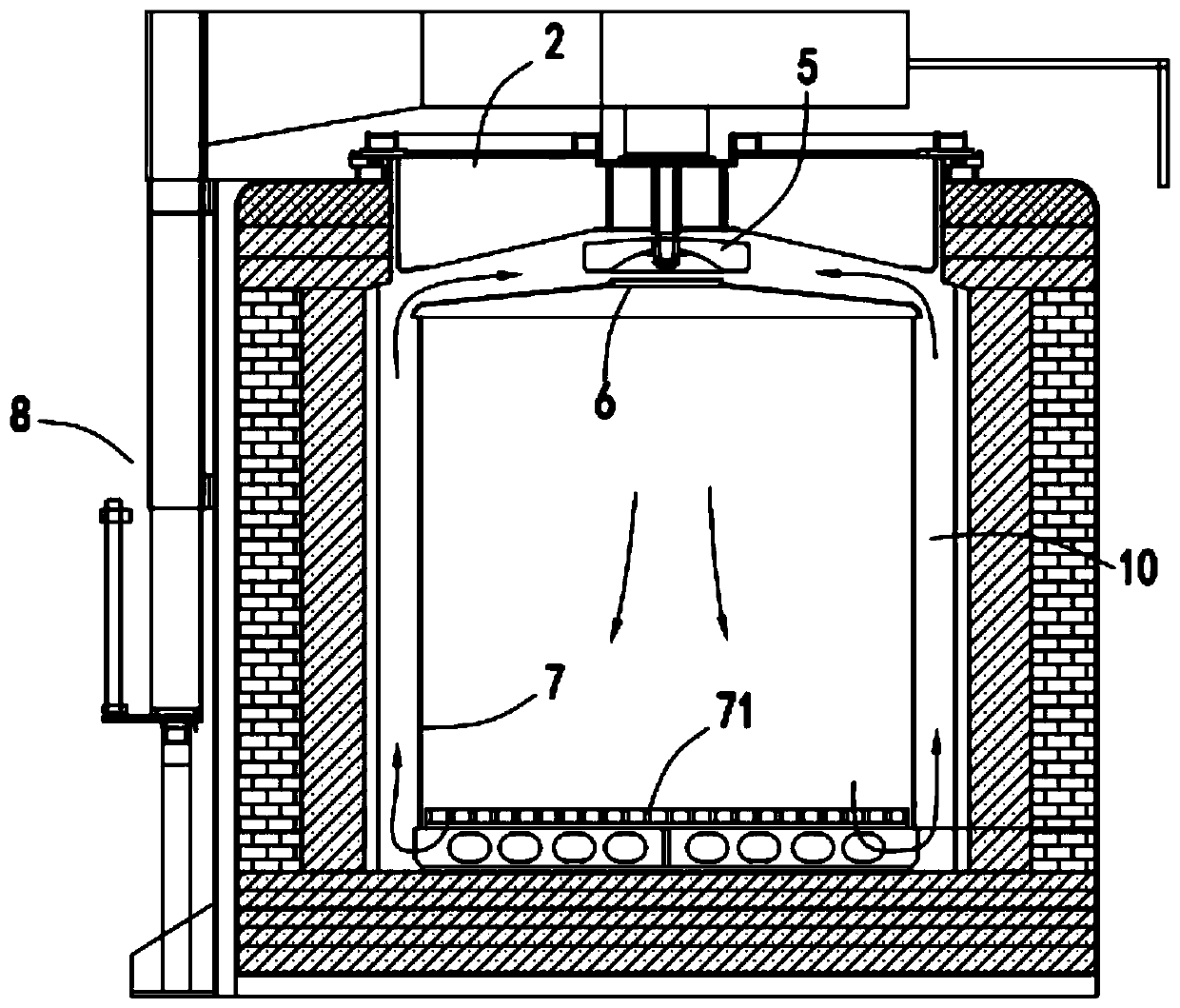

[0032] Such as Figure 1 to Figure 5 As shown, what is provided in this embodiment is a high-efficiency cooling industrial furnace, including a furnace body 1 and a furnace cover 2 arranged on the upper end of the furnace body 1 that can be opened and closed, and a heating assembly 3 is arranged on the inner wall of the furnace body 1 , the heating assembly 3 is provided in a hollow structure, and its two ends pass through the furnace wall 11 of the furnace body 1 and extend to the outside of the furnace body 1, and the two ends of the heating assembly 3 are respectively connected to positive and negative voltages, And one of the ends is the air inlet end, and the air inlet end is connected with the blower device 4 .

[0033] What is worth mentioning in the present invention is that by setting the heating assembly 3 as hollow, the two ends of its heating tube 31 are extended to the outside of the furnace body 1, and a voltage is applied to the heating tube 31, and one end The...

Embodiment 2

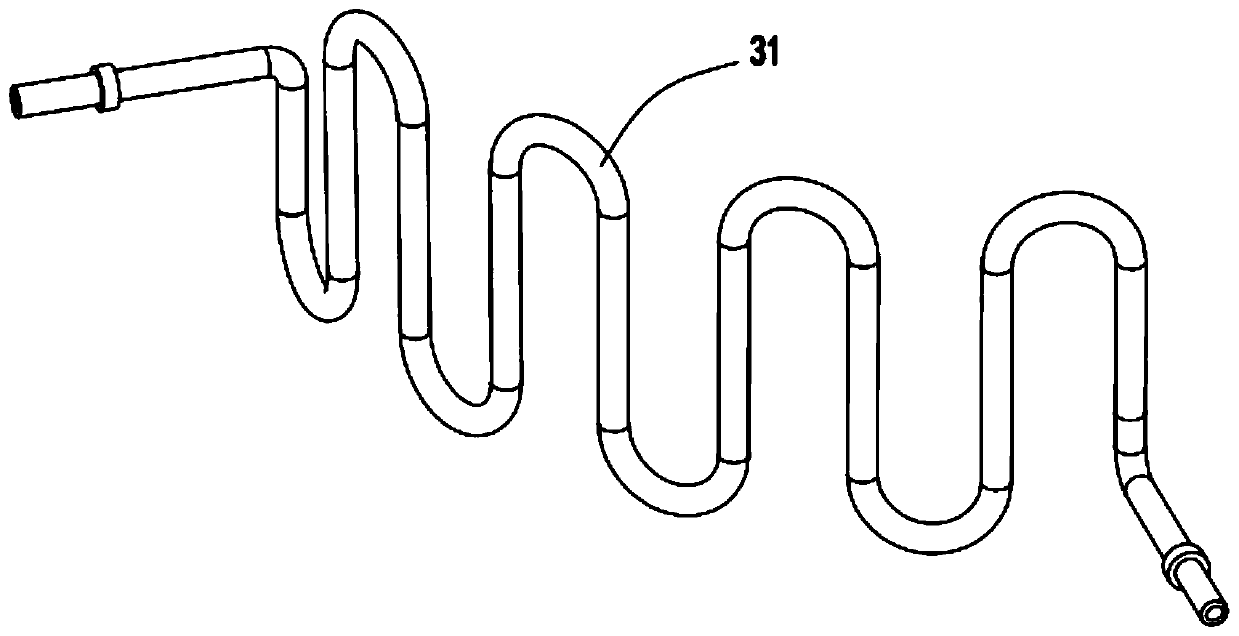

[0043] Such as figure 1As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, the heating assembly 3 includes at least one heating tube 31 arranged along the circumferential direction of the furnace body 1 , and the heating tube 31 is arranged in a curved shape.

[0044] In this embodiment, by setting the heating assembly 3, it can be combined by a plurality of heating pipes 31, so that a plurality of heating pipes 31 can be evenly distributed according to needs, so that there are a plurality of air inlets and air outlets, so that further Improve the cooling rate of the furnace and shorten the time of the entire heat treatment process of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com