A Furnace Temperature Control System for Isothermal Normalizing Furnace

A control system, a normalizing furnace technology, which is applied in the direction of heat treatment process control, furnaces, manufacturing tools, etc., can solve the problems that the structure and mechanical properties of the workpiece cannot reach the ideal state, cannot meet the cooling requirements, and the quenching effect is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

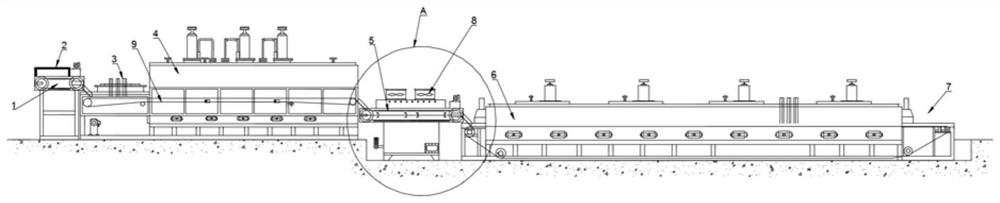

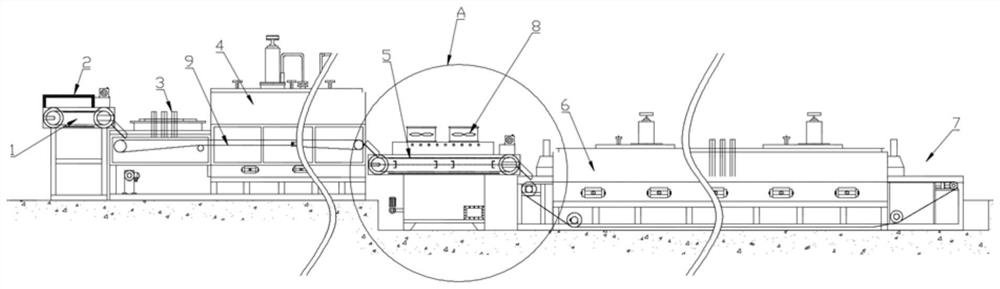

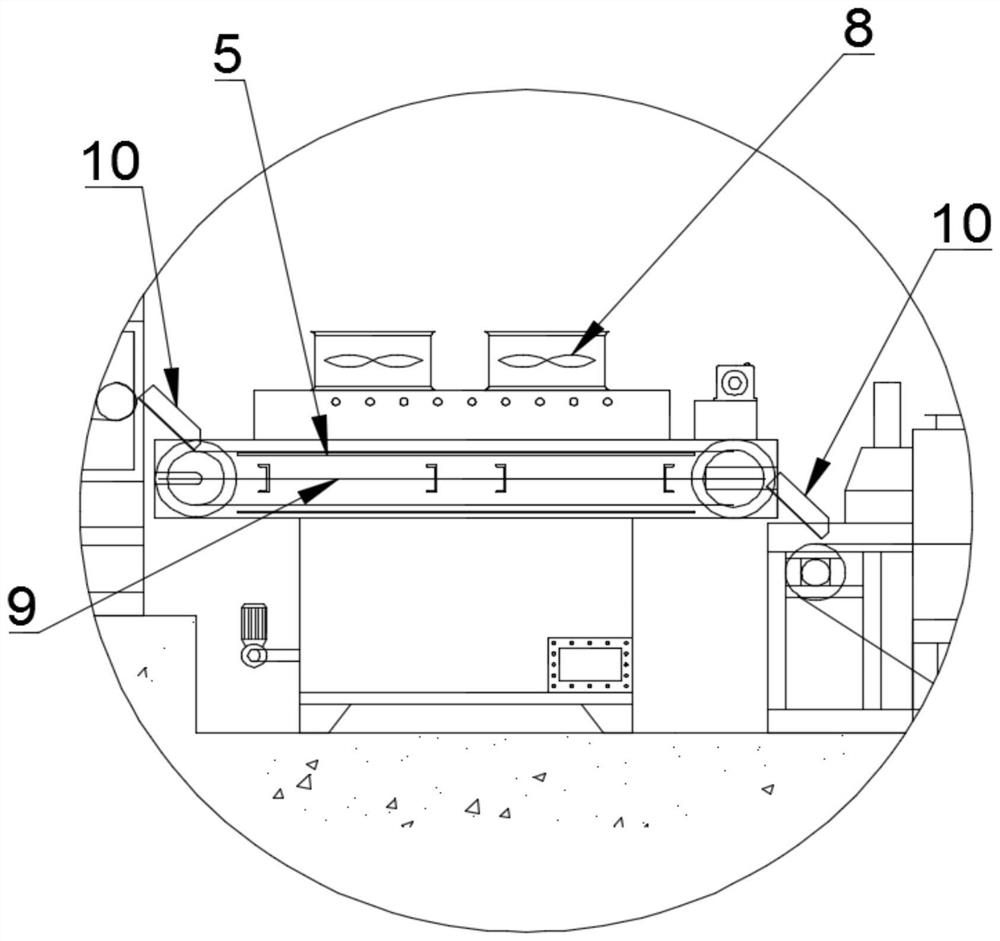

[0034]Embodiment 1: a furnace temperature control system of an isothermal normalizing furnace, comprising a feeding device 1, a preheating device, a spraying device 4, a secondary heating device 6 and a controller, and the feeding device 1 is arranged on the preheating One side of the device, the spraying device 4 is arranged on the other side of the preheating device, the side of the spraying device 4 away from the preheating device is provided with the secondary heating device 6, and the feeding The device 1, the preheating device, the spraying device 4 and the secondary heating device 6 are all equipped with transport devices, the feeding device 1, the preheating device, the spraying device 4, the The secondary heating devices 6 are arranged in sequence to form a production line, and the feeding device 1 , the preheating device, the spraying device 4 , the secondary heating device 6 and the transportation device are respectively connected to the controller under control. Th...

Embodiment 2

[0035] Embodiment two: a furnace temperature control system of an isothermal normalizing furnace, comprising a feeding device 1, a preheating device, a spraying device 4, a secondary heating device 6 and a controller, the feeding device 1 is arranged on the preheating One side of the device, the spraying device 4 is arranged on the other side of the preheating device, the side of the spraying device 4 away from the preheating device is provided with the secondary heating device 6, and the feeding The device 1, the preheating device, the spraying device 4 and the secondary heating device 6 are all equipped with transport devices, the feeding device 1, the preheating device, the spraying device 4, the The secondary heating devices 6 are arranged in sequence to form a production line, and the feeding device 1 , the preheating device, the spraying device 4 , the secondary heating device 6 and the transportation device are respectively connected to the controller under control. Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com