Steel structure assembly wallboard and assembly method thereof

An assembly method and assembly technology, which are applied to building components, protective buildings/shelters, monocarboxylic acid ester copolymer adhesives, etc., can solve the problems of large size of wall panels and inconvenient transportation and assembly of staff, etc. Achieve the effect of reducing the production area, simplifying the construction steps and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

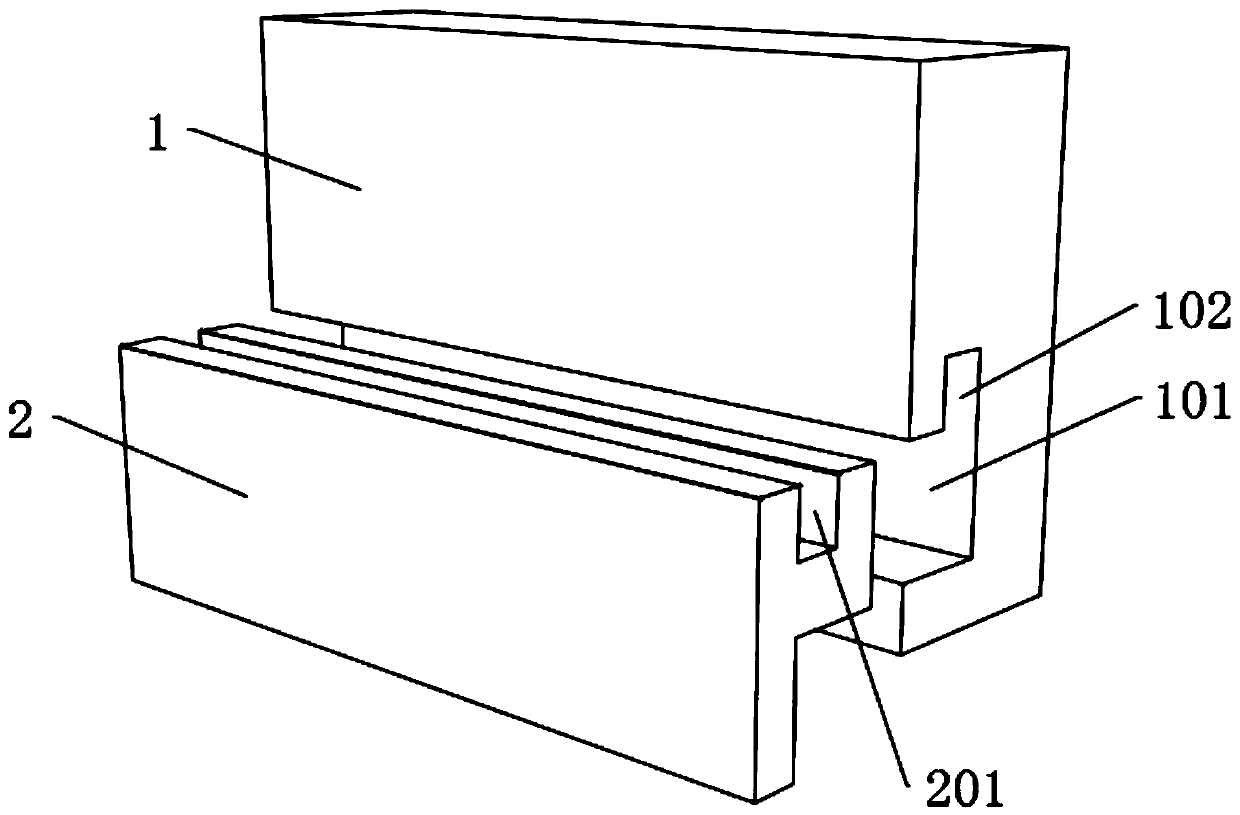

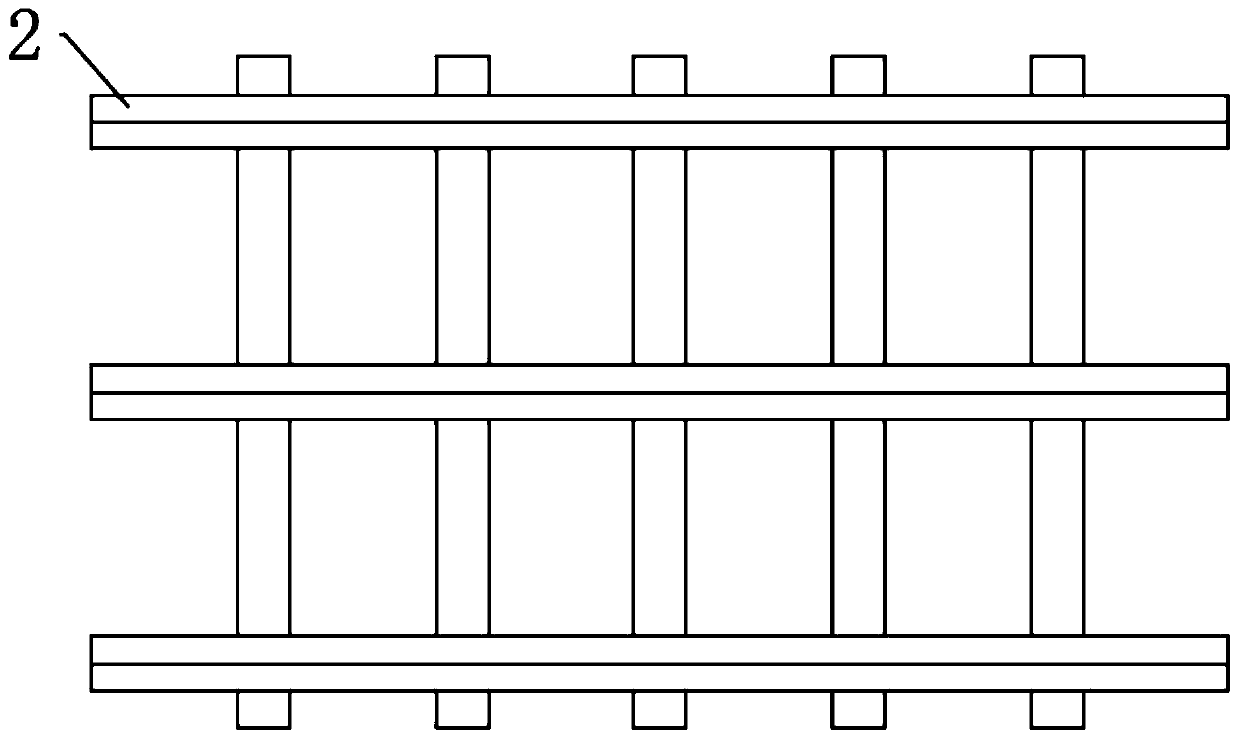

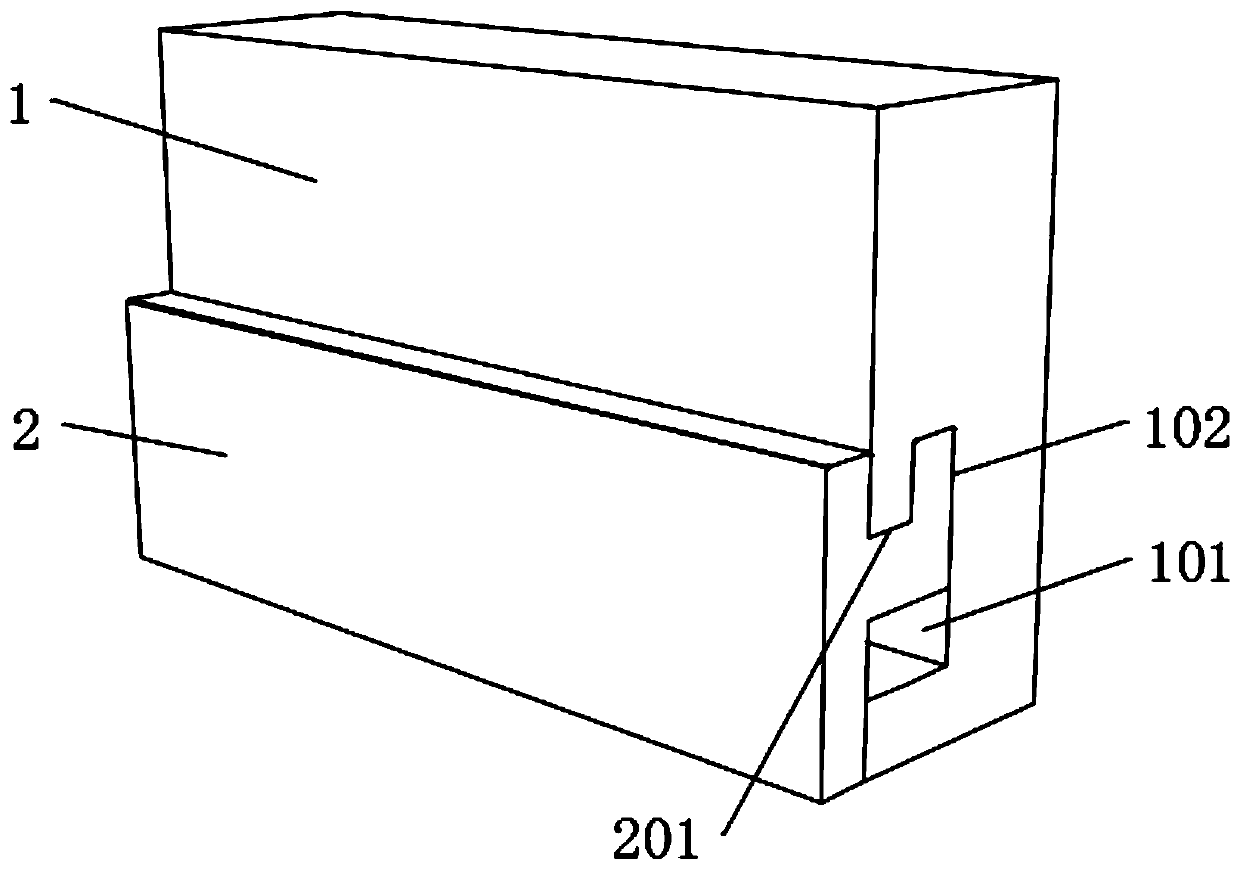

[0044] A steel structure assembled wall panel and an assembly method thereof, comprising a vertical steel support and a horizontal assembly steel support 2, the vertical steel support and the horizontal assembly steel support 2 are perpendicular to each other, and the vertical steel structure and the horizontal assembly steel support 2 pass through fastening bolts, see figure 1 , the upper end of the horizontal assembly steel bracket 2 is dug with a second bayonet groove 201, the outer end of the horizontal assembly steel bracket 2 is provided with a prefabricated wall panel body 1, and the end of the prefabricated wall panel body 1 close to the horizontal assembly steel bracket 2 is dug with a mounting groove 101, the upper end wall of the installation groove 101 is dug with a first bayonet groove 102, the installation groove 101 is connected with the first bayonet groove 102, the second bayonet groove 201 is matched with the assembled wallboard body 1, and the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com