Improved ceiling fan lamp structure

A technology for ceiling fan lights and fans, applied in electromechanical devices, lighting and heating equipment, electrical components, etc., can solve the problems of very high requirements for blade installation process, large overall height, and difficult process, so as to avoid excessive stretching or compression. Failure, small overall height, avoid the effect of blade overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

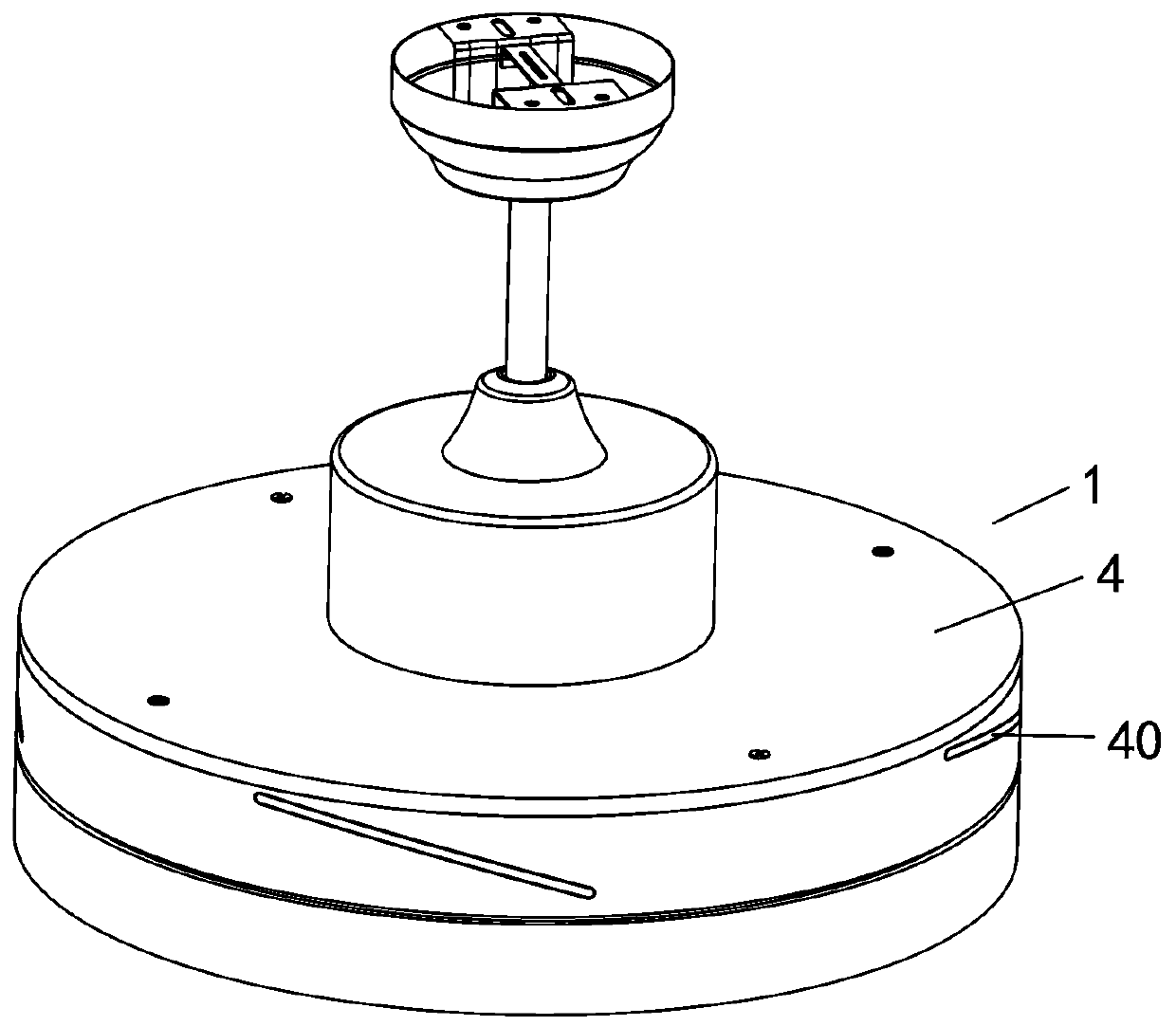

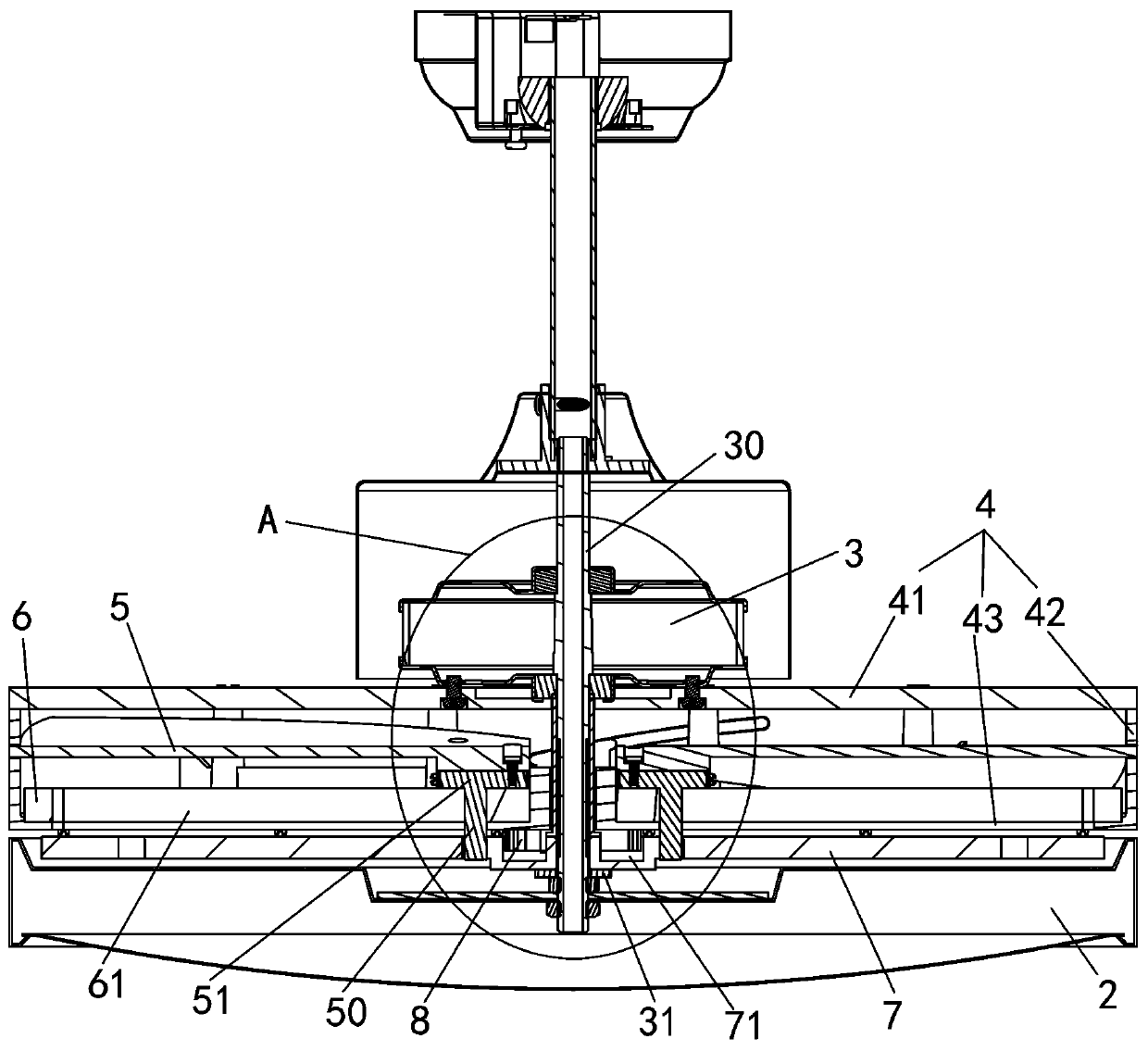

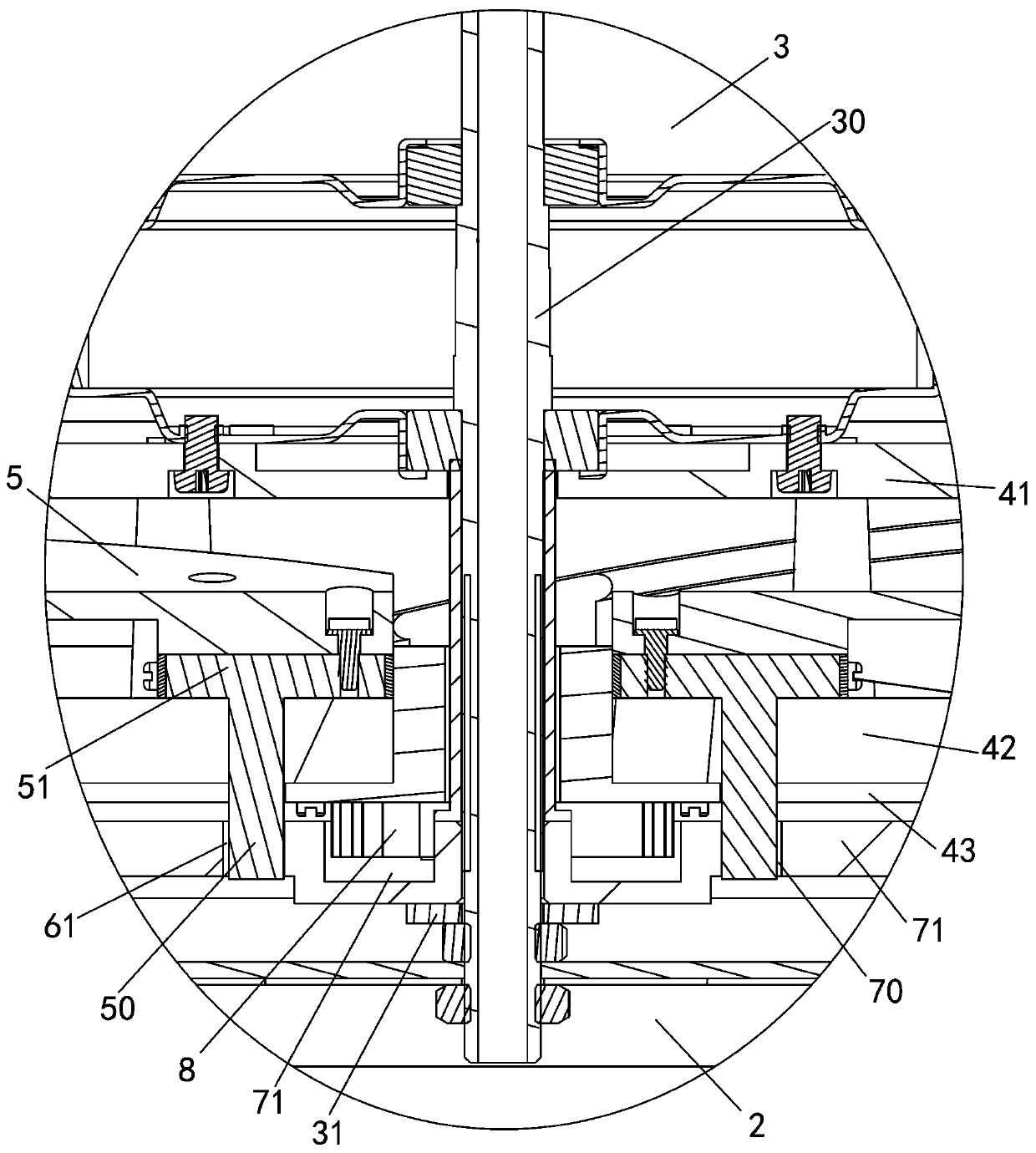

[0029] Such as Figure 1 to Figure 7 As shown, an improved structure of a ceiling fan lamp includes a fan part 1 and a lamp part 2. The fan part 1 is arranged on the upper part of the lamp part 2. The fan part 1 includes a motor 3, a blade storage cover 4, a blade 5, and a blade Guide rail 6 and synchronous disc 7, motor 3 is outer rotor motor 3, and blade storage cover 4 comprises top cover 41, annular sidewall 42 and rotating disk 43, and annular sidewall 42 is surrounded on the upper surface periphery of rotating disk 43, and rotating disk The center of 43 has shaft hole 44, has blade inlet and outlet hole 40 on the annular side wall 42, and the shape of blade inlet and outlet hole 40 is adapted to blade 5, and top cover 41 is fixed on the upper opening of annular side wall 42, and top cover 41 center openings There is a through hole 45, the motor 3 housing is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com