Bottom pressurization oil supply type self-lubricating windshield wiper motor

A self-lubricating and wiper technology, which is applied in the direction of gear lubrication/cooling, mechanical equipment, transmission parts, etc., can solve problems such as inability to recycle lubricating oil, overheating of the motor deceleration mechanism, and affect service life, etc., to achieve a wide range of lubrication, Avoid lubricating dead angle and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

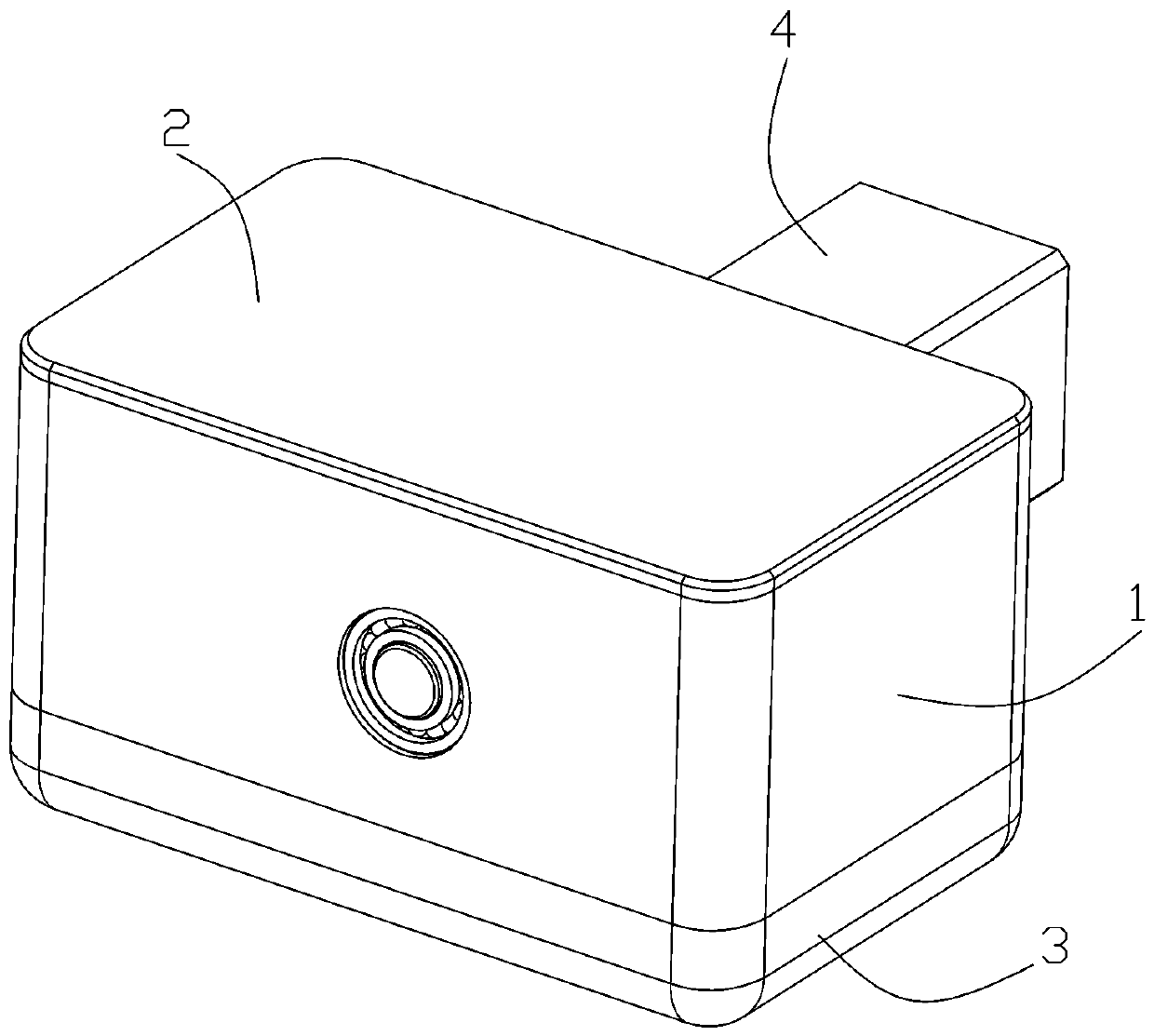

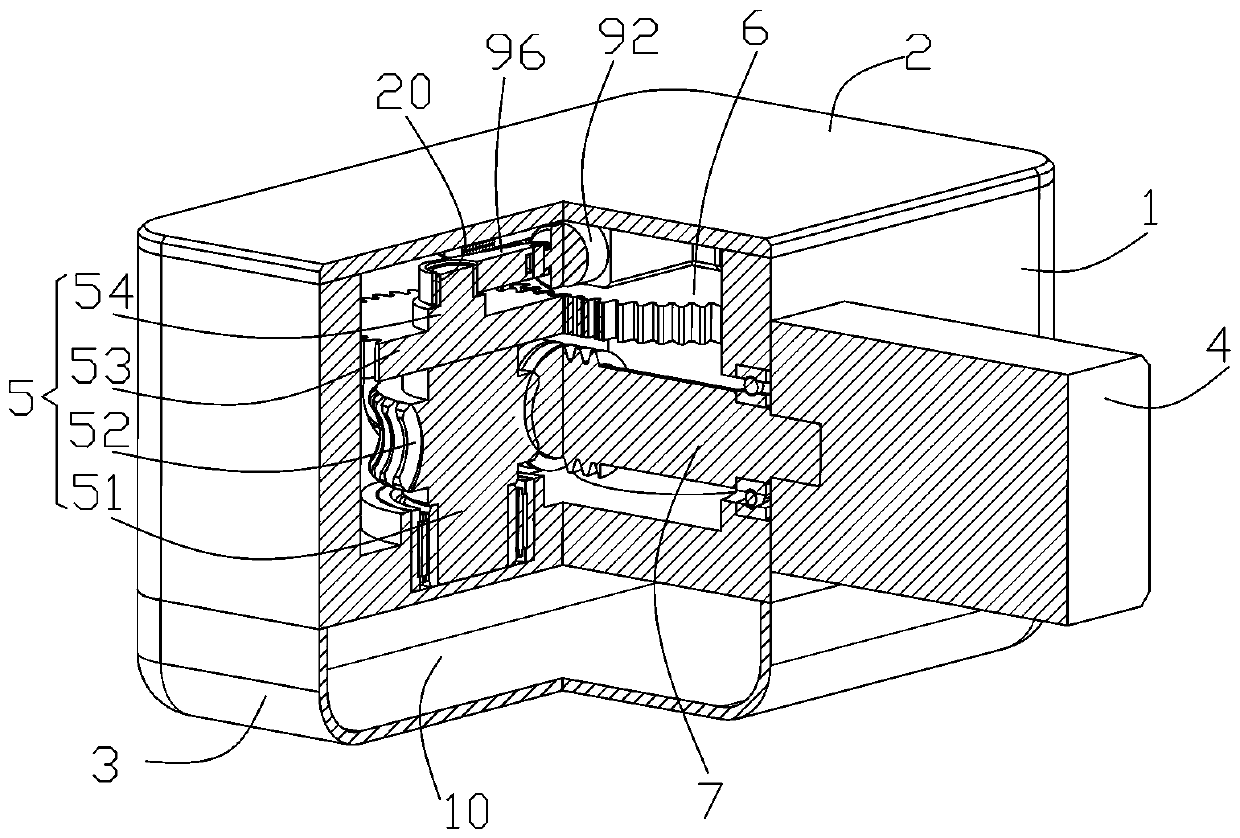

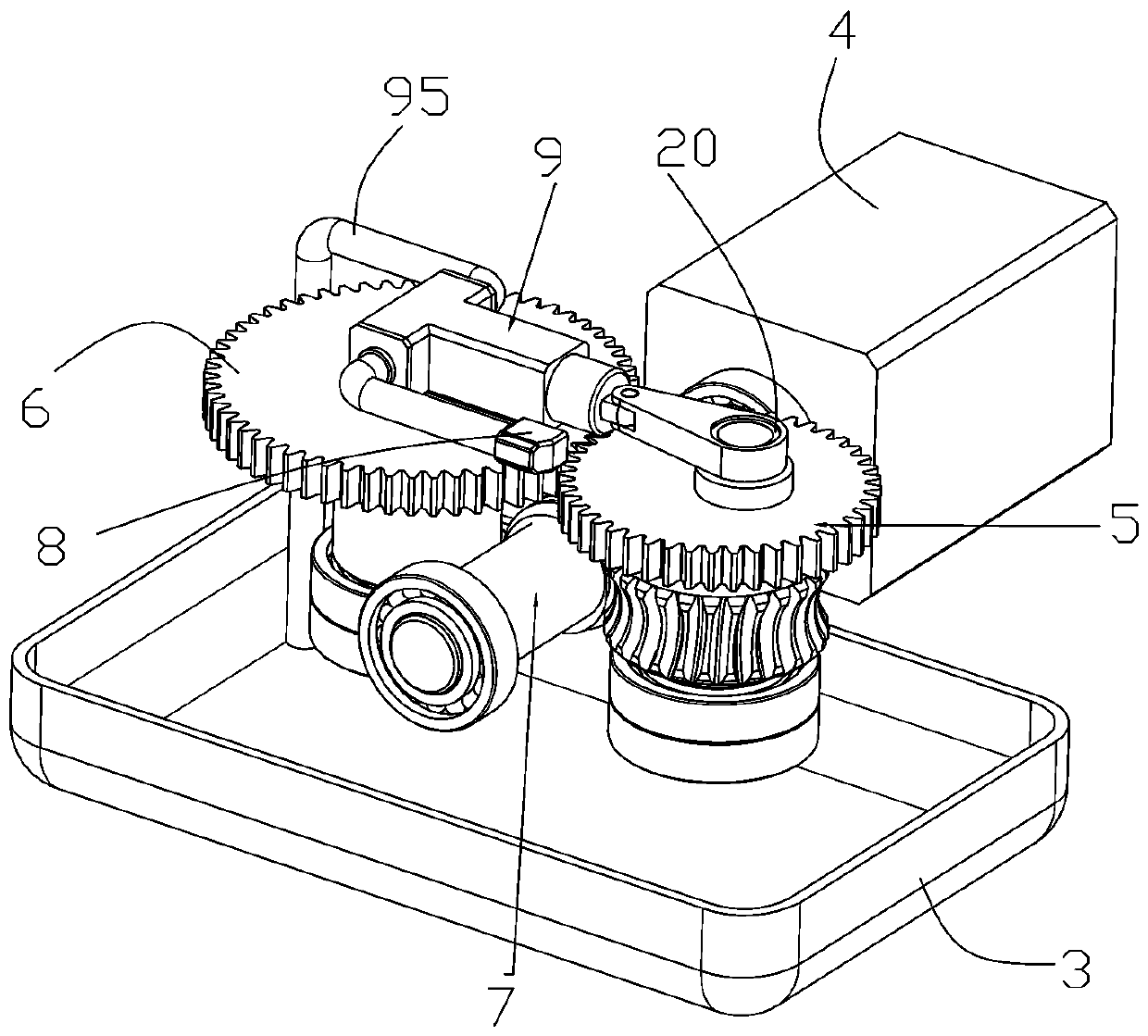

[0018] like Figure 1 to Figure 5 As shown, the self-lubricating wiper motor of a bottom pressurized oil supply type described in this embodiment includes a gear box 1 with an opening, a box upper cover 2, an oil sump 3, a driving motor 4, and a gear box located on the gear box. The driving turbine 5, the driven gear 6, the transmission worm 7, the atomizing nozzle 8 and the pressurized plunger pump 9 in the casing 1; the casing upper cover 2 is covered on the top of the gear casing 1; the oil The top of the bottom groove 3 is connected to the bottom of the gear case 1, thereby forming a sealed oil storage chamber 10, and lubricating oil is stored in the oil storage chamber 10. The gear case 1 is provided with an oil return hole 11, and the The oil return h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com