Refrigeration pipeline assembly with defrosting function, evaporator and refrigeration equipment

A technology for refrigeration tubes and evaporators, which is applied in refrigeration components, evaporators/condensers, refrigerators, etc., and can solve the problems of outer wall insulation or protective layer wear and tear of heating parts, deformation or bending of aluminum tubes, and water storage that cannot be discharged outside and other problems, to achieve the effect of improving the cooling effect, fast defrosting speed, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

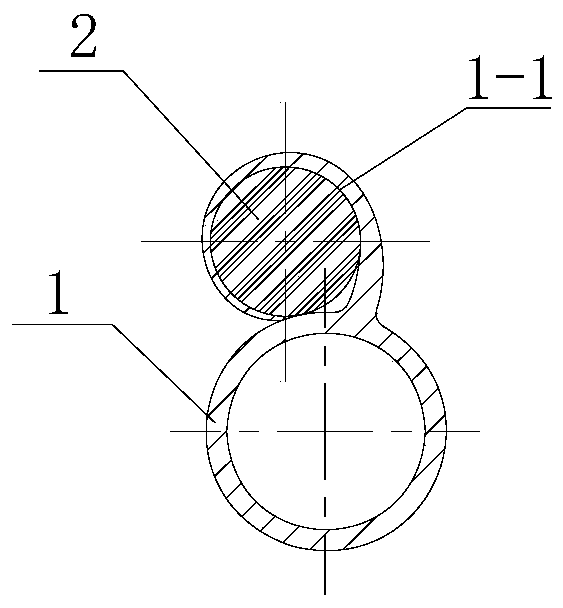

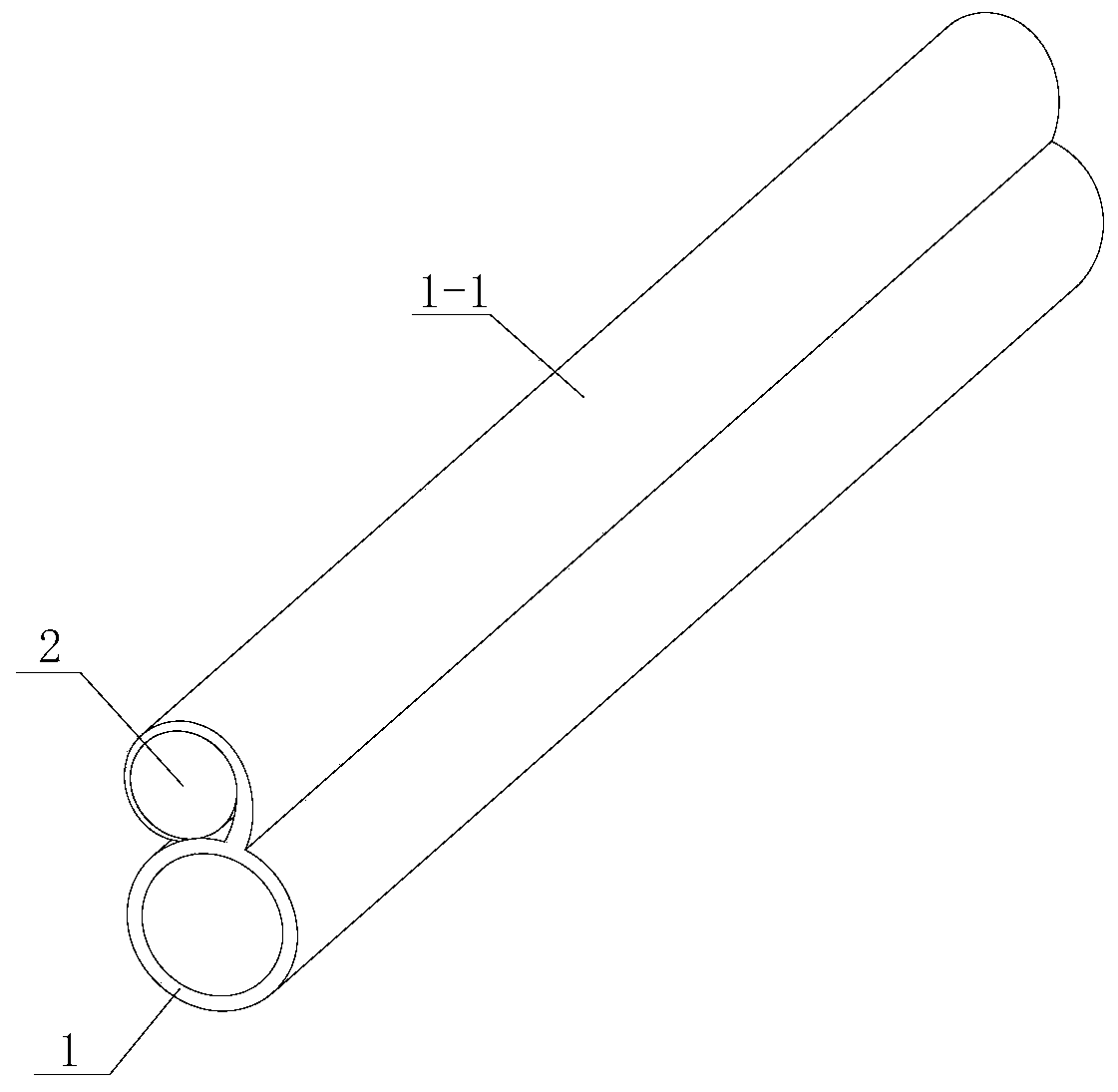

[0049] Example 1, see Figure 1 to Figure 3 ; A refrigeration pipeline assembly with a defrosting function, used in a refrigeration system, comprising a continuous refrigerant delivery pipe 1 with an inlet and an outlet, which is used to deliver a refrigerant medium; The heating pipe 2 is used for defrosting; the outer surface of the refrigerant delivery pipe is provided with a wrapping part 1-1 along the length direction of the refrigerant delivery pipe, and the wrapping part is integrally formed with the refrigerant delivery pipe; the wrapping part and the refrigerant delivery pipe are integrally formed. The thickness of the junction of the refrigerant delivery pipe is greater than the thickness of the extension of the wrapping part, and the thickness is linearly decreasing from the junction of the wrapping part and the refrigerant delivery pipe to the extension of the wrapping part; The heating tube is tightly wrapped to keep the electric heating tube in a static state rela...

Embodiment 2

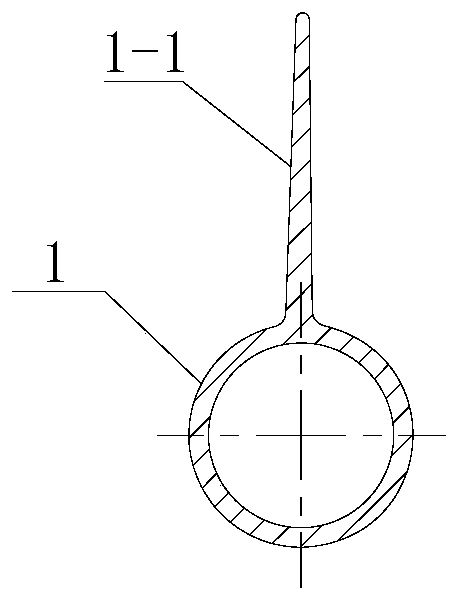

[0051] Example 2: see Figure 4 to Figure 5 ; On the basis of Embodiment 1, an arc-shaped placement groove 1-2 equal to the outer diameter of the electric heating tube 2 is provided along the length direction on the refrigerant delivery pipe 1 near the root side of the wrapping part; The heating tube is placed in the arc-shaped placement slot, and the outer wall of the electric heating tube is attached to the outer wall of the placement slot. In this way, on the basis of Example 1, the contact area between the electric heating tube and the refrigerant delivery tube is increased, the heat exchange efficiency is improved, and the defrosting speed is accelerated. When the electric heating tube deviates, the production efficiency is improved. When the evaporator is wound, the seam is set to be slanted downward in order to facilitate drainage.

Embodiment 3

[0052] Example 3: See Figure 6 to Figure 7 ; A refrigeration pipeline assembly with a defrosting function, used in a refrigeration system, comprising a continuous refrigerant delivery pipe 1 with an inlet and an outlet, which is used to deliver a refrigerant medium; The heating pipe 2 is used for defrosting; the outer surface of the refrigerant conveying pipe is provided with two wrapping parts 1-1 along the length direction of the refrigerant conveying pipe, and the wrapping parts are integrally formed with the refrigerant conveying pipe; The height of the wrapping part is not less than the radius of the electric heating tube; the height of the two wrapping parts in this embodiment is greater than the radius of the electric heating tube, smaller than the diameter of the electric heating tube, and the upper ends of the two wrapping parts are not closed after wrapping; The heating tube is placed between the two wrapping parts, and the two wrapping parts are relatively bent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com