Brake strength test bed

A technology for strength testing and machine gates, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. It can solve the problems of load-bearing columns, optimal design of beams, and lack of overall control of the test bench, so as to facilitate later expansion. , good operability and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

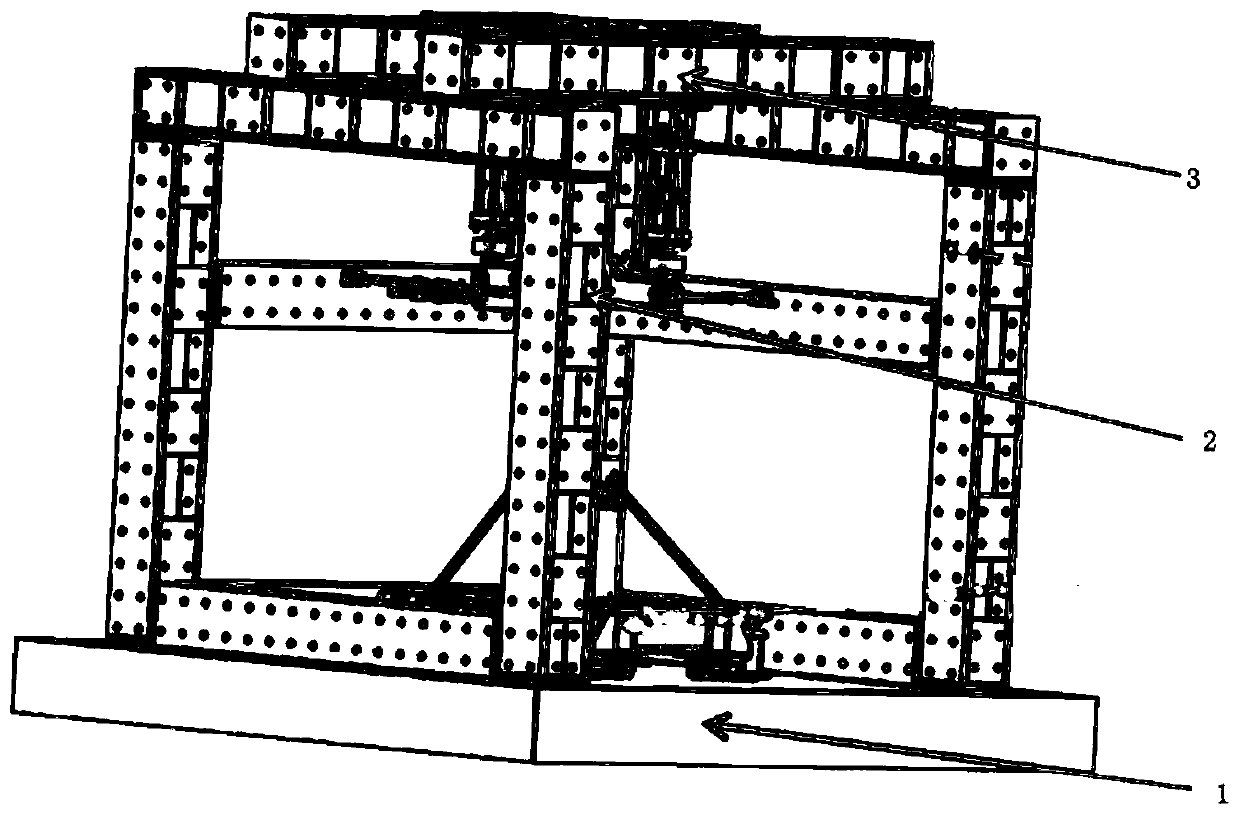

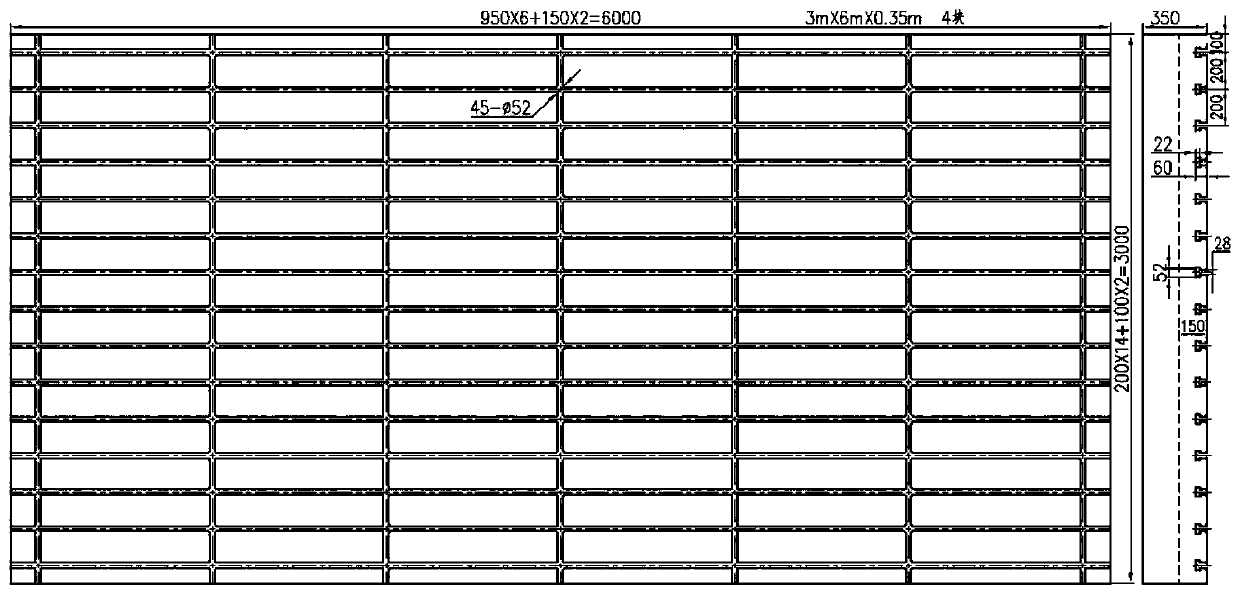

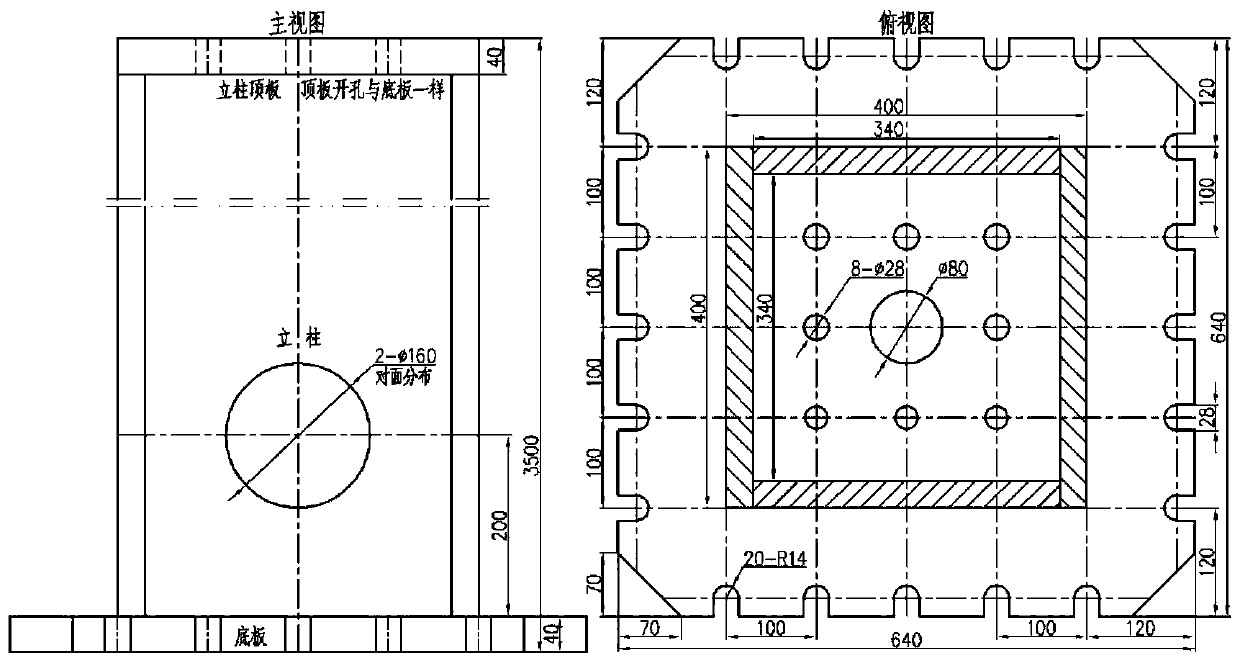

[0037] Such as figure 1 As shown, the machine gate strength test bench is composed of mechanical parts, hydraulic system, actuator assembly, control system, testing system and monitoring system. 2 and the load-bearing beam 3 set on the load-bearing column 2, the actuator assembly is installed on the load-bearing beam 3; the hydraulic system includes a high-pressure oil source that provides the total pressure oil for the system, and a hydraulic substation that controls the hydraulic oil supply state of the test bench , the oil distribution module connected with the hydraulic substation and the matching pipeline, the oil distribution module is connected to the actuator assembly; the control system includes a hydraulic control system and a multi-channel loading control system; the test system is modular in design and can be expanded infinitely to support various The monitoring system is divided into a video monitoring subsystem and a field communication subsystem, which are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com